Aluminum alloy material and production method therefor, and aluminum alloy cladding material using aluminum alloy material

An aluminum alloy material and aluminum alloy technology, applied in the field of aluminum alloy materials, can solve problems such as inappropriate anti-corrosion methods, accelerated corrosion speed, and difficulties in high corrosion resistance of thin-walled materials, and achieve easy and cheap formation and environmental burden Small, good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

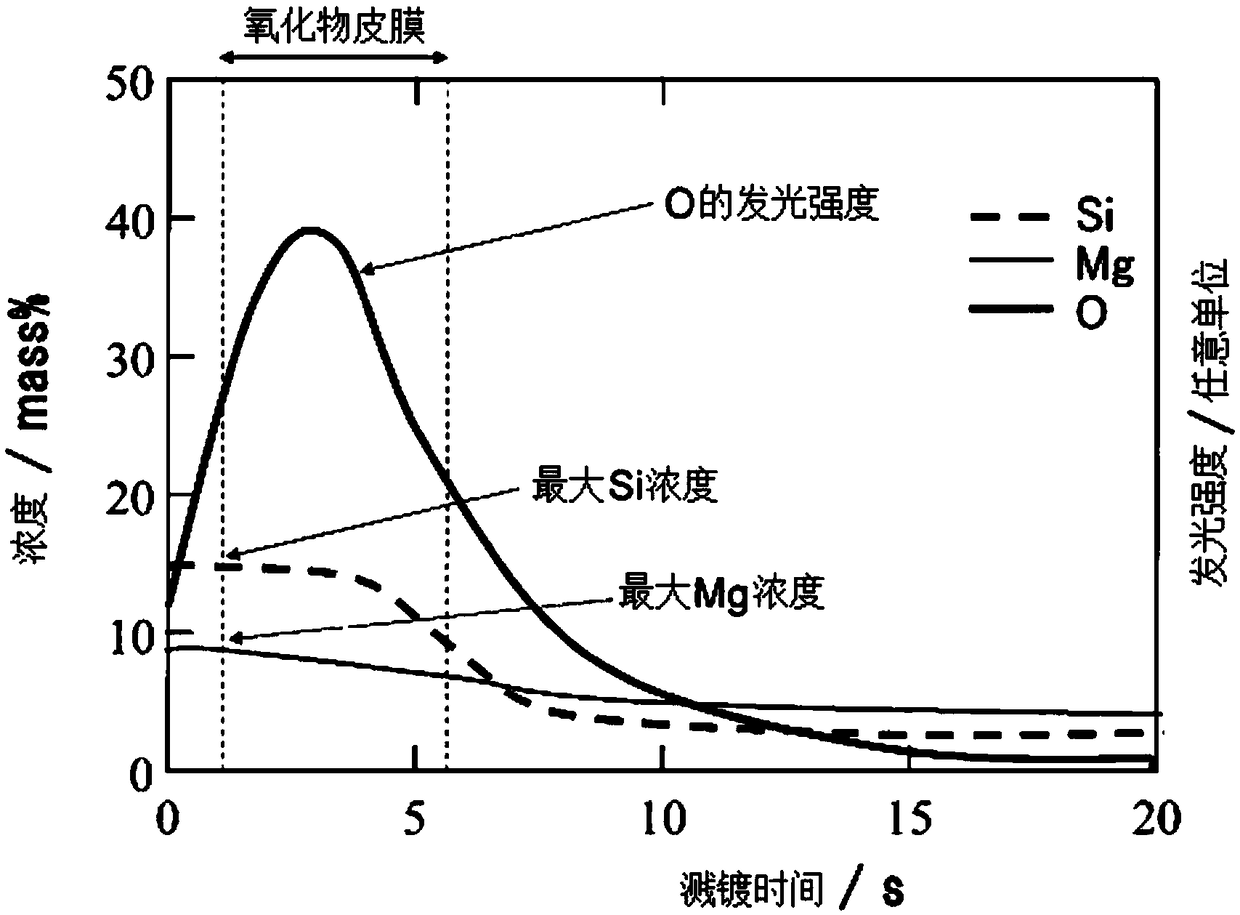

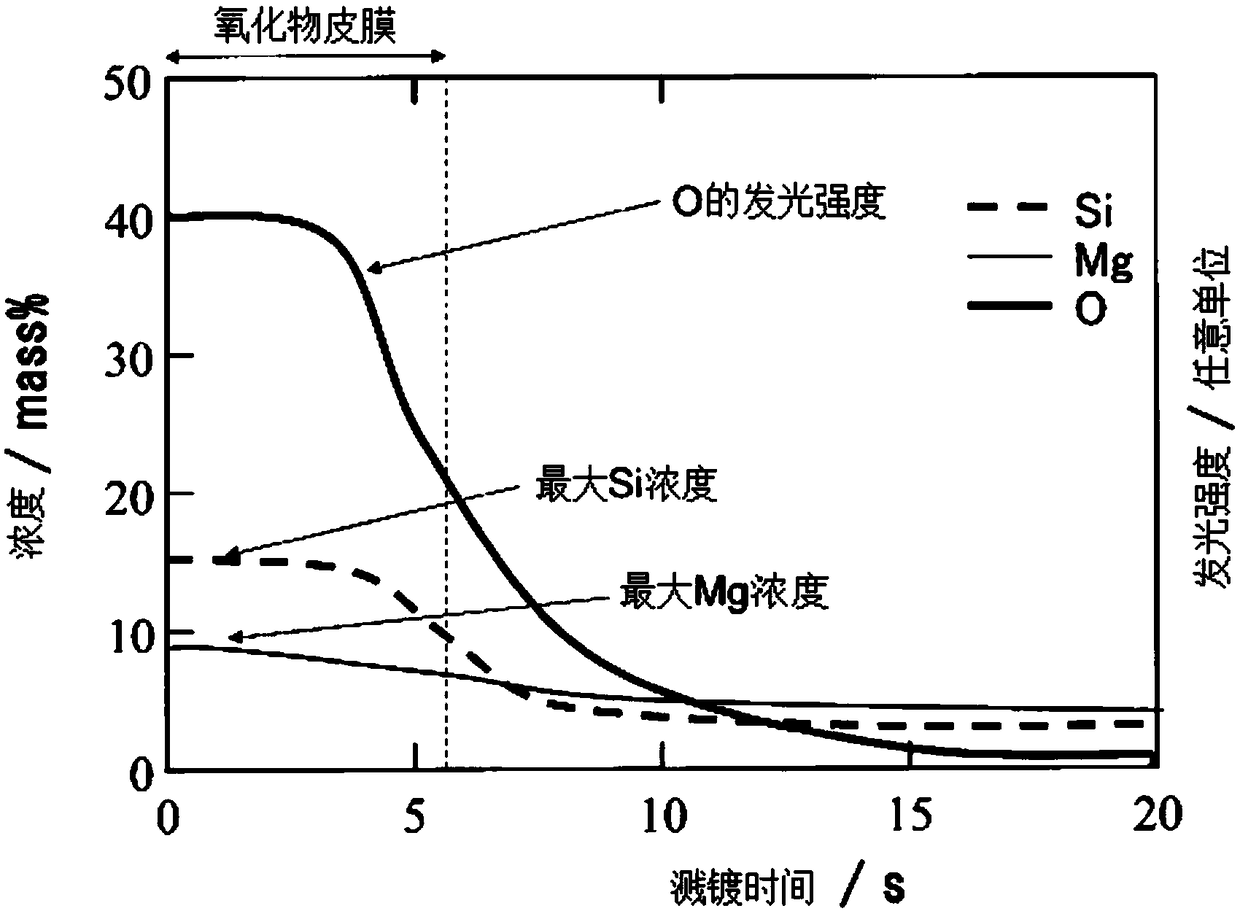

Method used

Image

Examples

Embodiment

[0086] Next, the present invention will be described in further detail based on examples. These examples are merely illustrations for explaining the present invention, and do not limit the technical scope of the present invention.

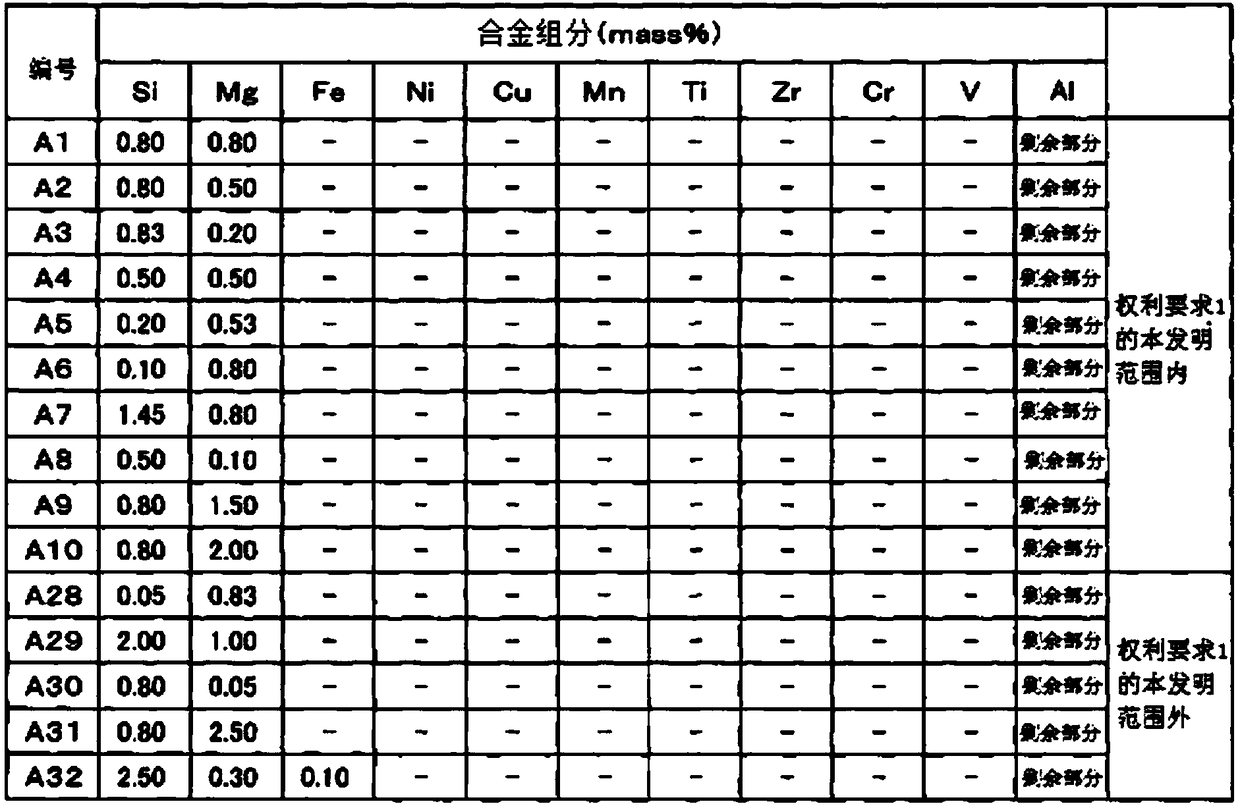

[0087] As the aluminum alloy material, alloys having the compositions shown in Table 1 and Table 2 were used. These alloys were cast by a semi-continuous casting method at a cooling rate of 3° C. / sec in order to prevent the formation of coarse Mg—Si-based crystals. After casting, surface cutting was performed, and a homogenization treatment was performed at a temperature of 500° C. for 3 hours in order to homogenize the metal structure and re-dissolve the coarse Mg—Si-based crystals. The casting method and homogenization process described above can also be applied to sheet and extruded materials.

[0088] Table 1

[0089]

[0090] Table 2

[0091]

[0092] An uncoated veneer (hereinafter, simply referred to as a veneer) is produced as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com