Initiator and gas generator

A detonator and end plate technology, which is applied in blasting barrels, weapon accessories, transportation and packaging, etc., can solve the problems of labor-intensive manufacturing and high cost, and achieve the effect of reducing manufacturing costs and making it easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

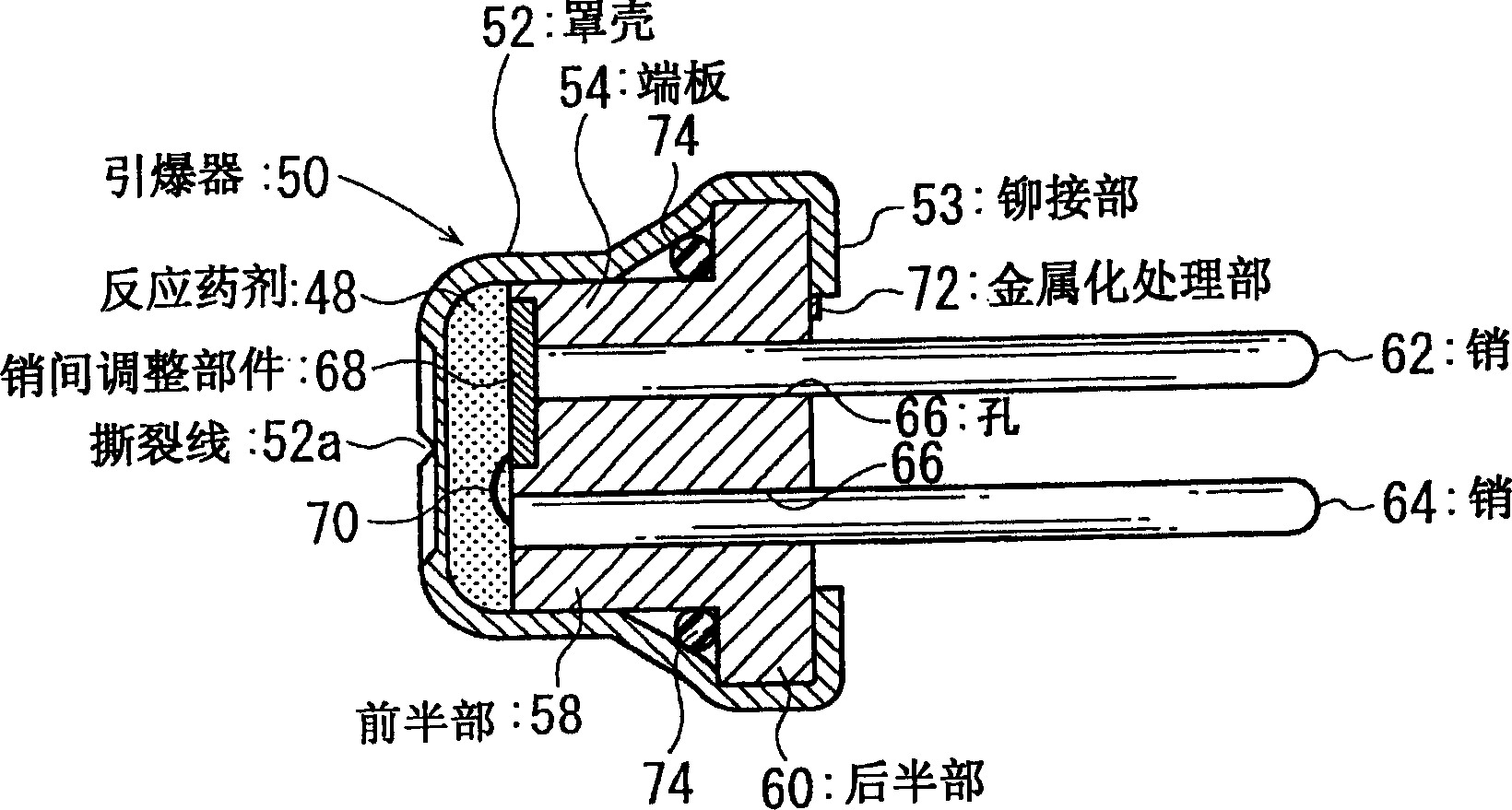

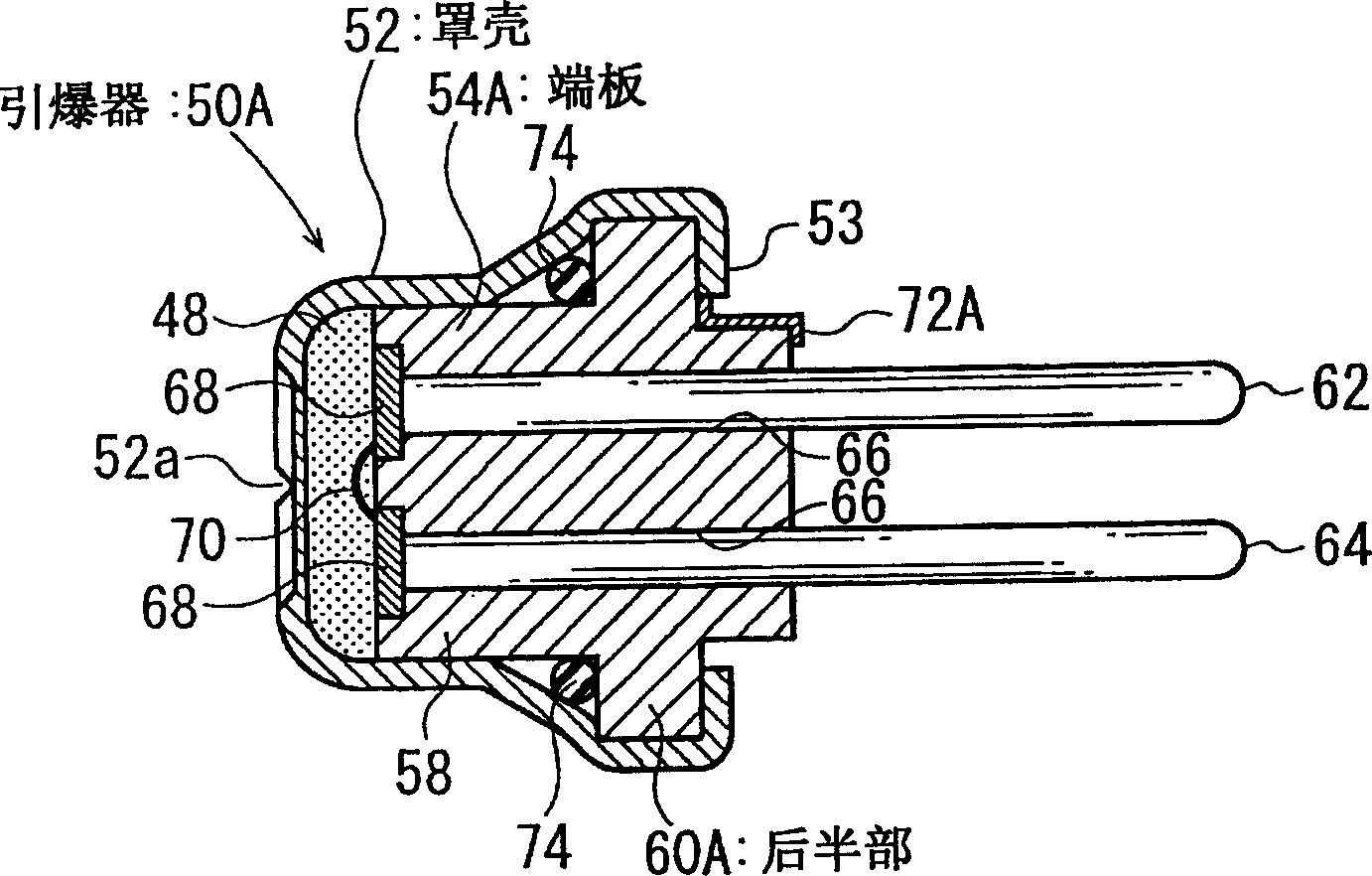

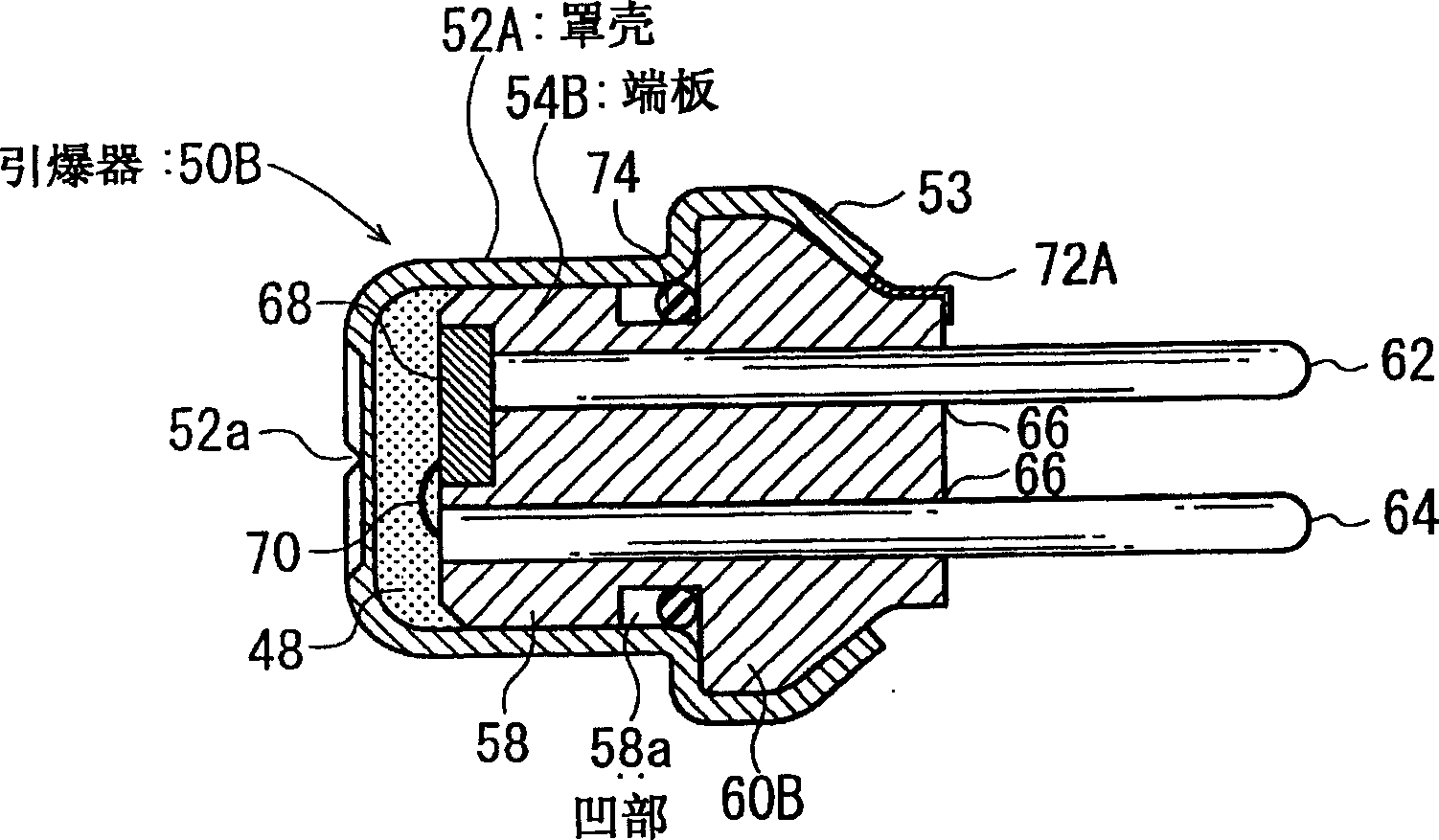

[0035] Embodiments will be described below with reference to the drawings. Figure 1 ~ Figure 4 (a) and Figure 5 All are cross-sectional views of detonators according to embodiments of the present invention, Figure 4 (b) is a perspective view of the electrode pin in figure (a).

[0036] figure 1 The detonator is equipped with a ceramic end plate 54 inserted into a case 52 made of SUS304 or the like and an inlet portion of the case 53, and a reaction agent is filled between the case 52 and the top end surface of the end plate 54. 48.

[0037] In this embodiment, the end plate 54 is composed of a small-diameter cylindrical front half 58 and a large-diameter cylindrical rear half 60 connected to the rear end of the front half 58 .

[0038] A pair of holes 66 penetrating in the thickness direction of the end plate are provided in the central portion of the end plate 54 . Electrode pins (hereinafter, simply referred to as pins) 62 and 64 are inserted into the holes 66 at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com