Electrostatic protection component and production method therefor

A technology of electrostatic protection and manufacturing method, which is applied in the direction of electrical components, circuits, varistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Embodiments of the present invention will be described in detail below based on the accompanying drawings.

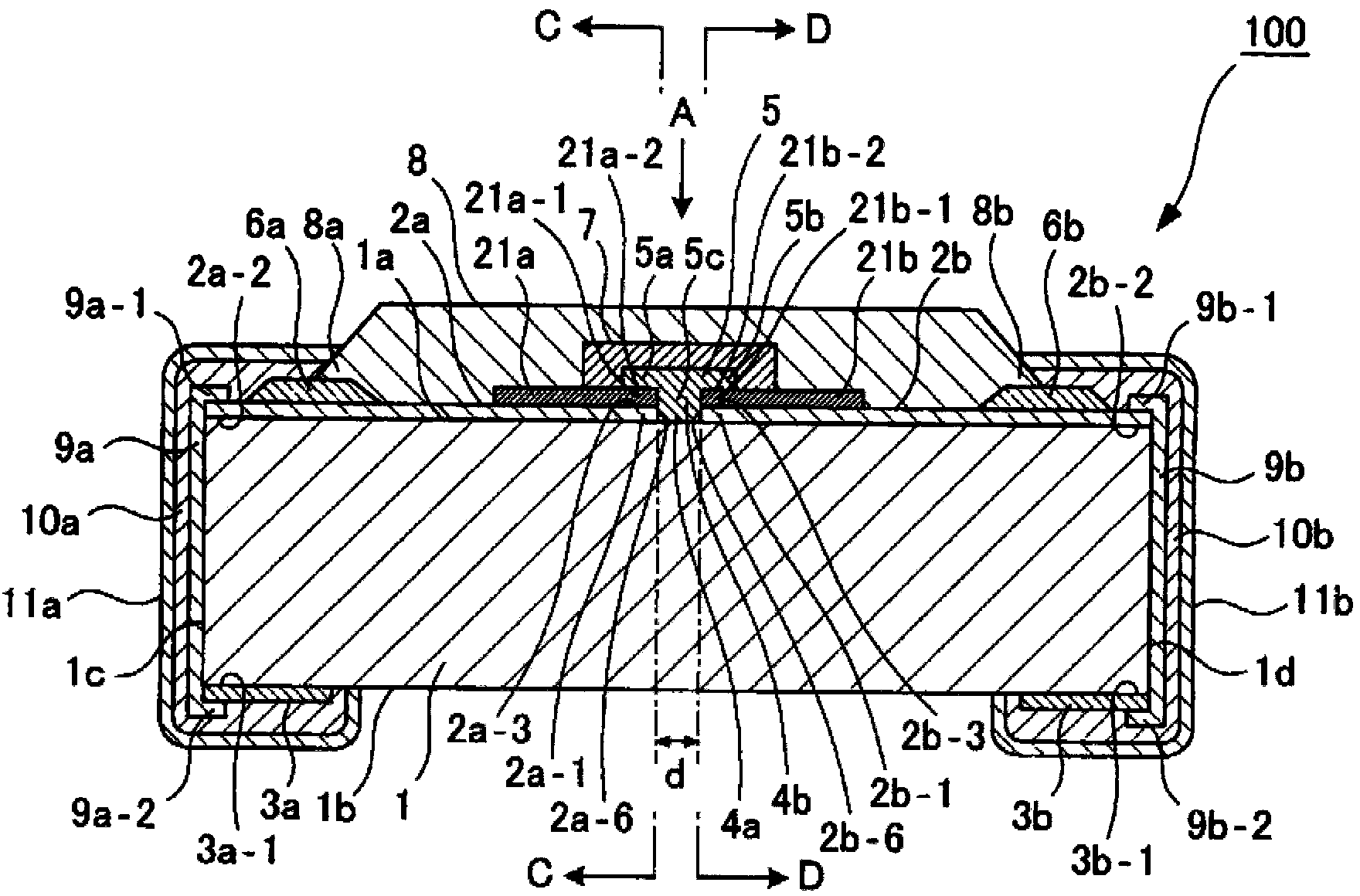

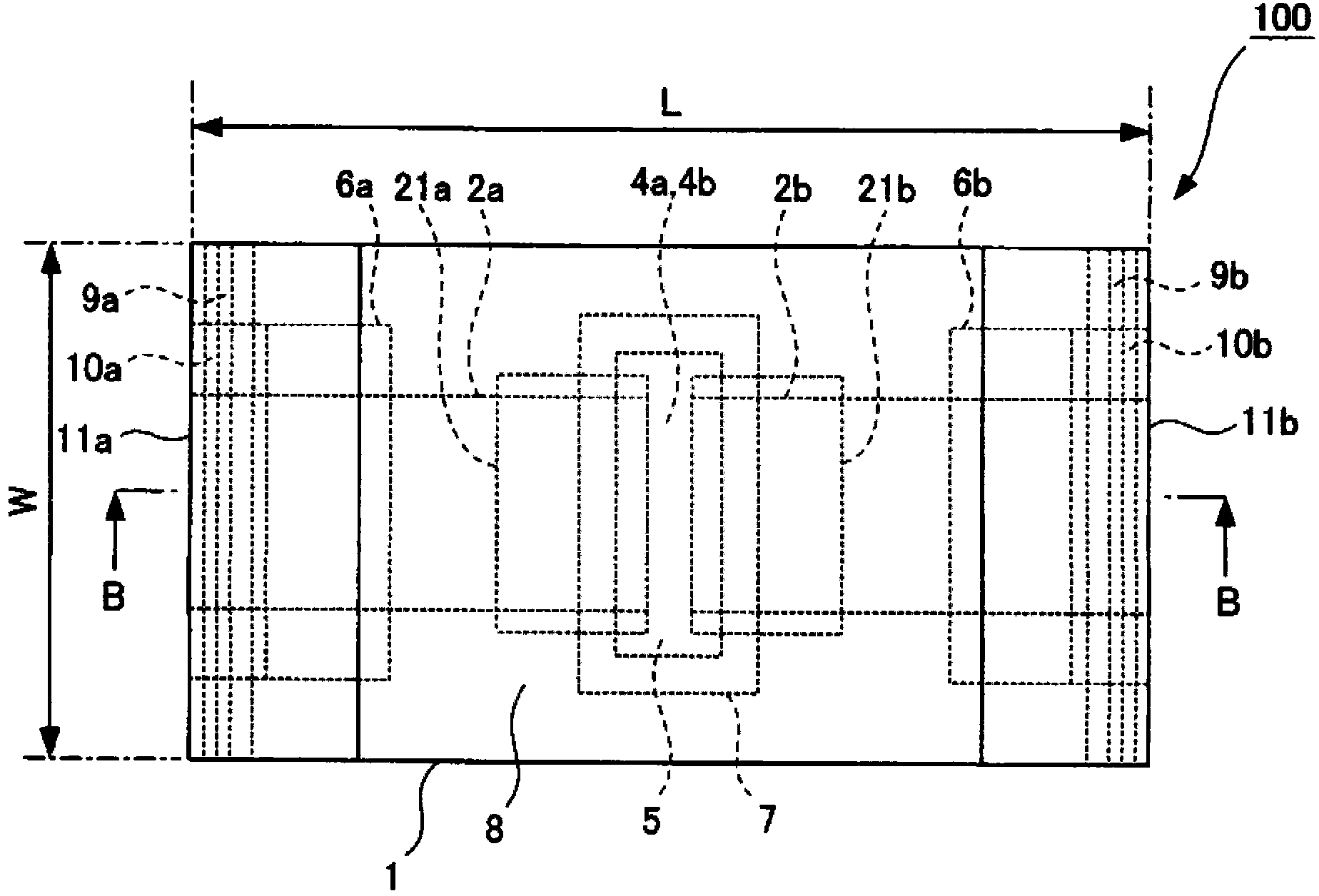

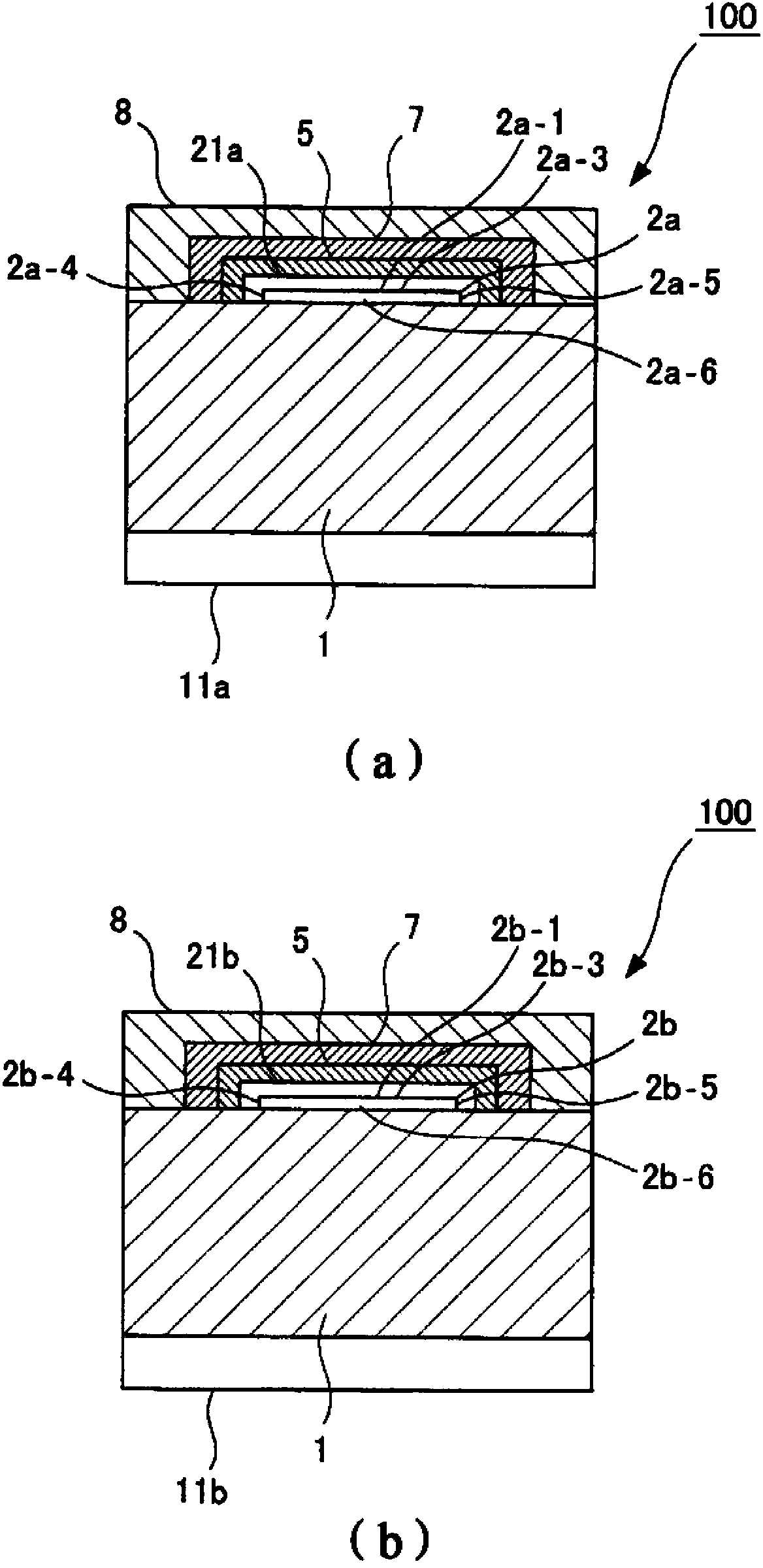

[0074] First, according to Figure 1~Figure 3 , illustrating the structure of the electrostatic protection component of the embodiment of the present invention.

[0075] Figure 1~Figure 3 The electrostatic protection component 100 shown is a component for surface mounting on a printed substrate of an electronic device such as a portable information device, in order to protect an electronic circuit (electronic component) mounted on the printed substrate from static pulses, external noise, etc. The overvoltage generated by the electronic device is placed between the wire that may be applied with the overvoltage and the ground.

[0076] Such as Figure 1~Figure 3 As shown, surface electrodes 2a, 2b are formed on a surface 1a of a ceramic substrate 1, which is an insulating substrate, and rear electrodes 3a, 3b are formed on a rear surface 1b of the ceramic subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com