A metal sulfide-loaded mesoporous carbon catalyst, preparation method and application thereof

A metal sulfide and catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of restricting the development of fuel cells and high cost of use, and achieve the effects of controllable metal sulfide, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Add 0.4mL of aniline, 0.3mL of pyrrole and 0.06mL of Triton X-100 into 60mL of deionized water, and sonicate to obtain a uniform mixture;

[0035] (2) 1mmol ferric nitrate nonahydrate and 1mmol cobalt nitrate hexahydrate are added to the mixed solution in step (1), and stirred to obtain a new mixed solution;

[0036] (3) Add 20mL of ammonium persulfate aqueous solution with a concentration of 0.05g / mL to the mixed solution in step (2), then immediately place the mixed solution at 3°C for 24 hours of polymerization, and use the mixed solution after the polymerization reaction is completed Rotary evaporator (evaporating temperature 90°C, negative pressure inside the bottle is 0.2MPa) evaporated excess water and dried to obtain a black intermediate product;

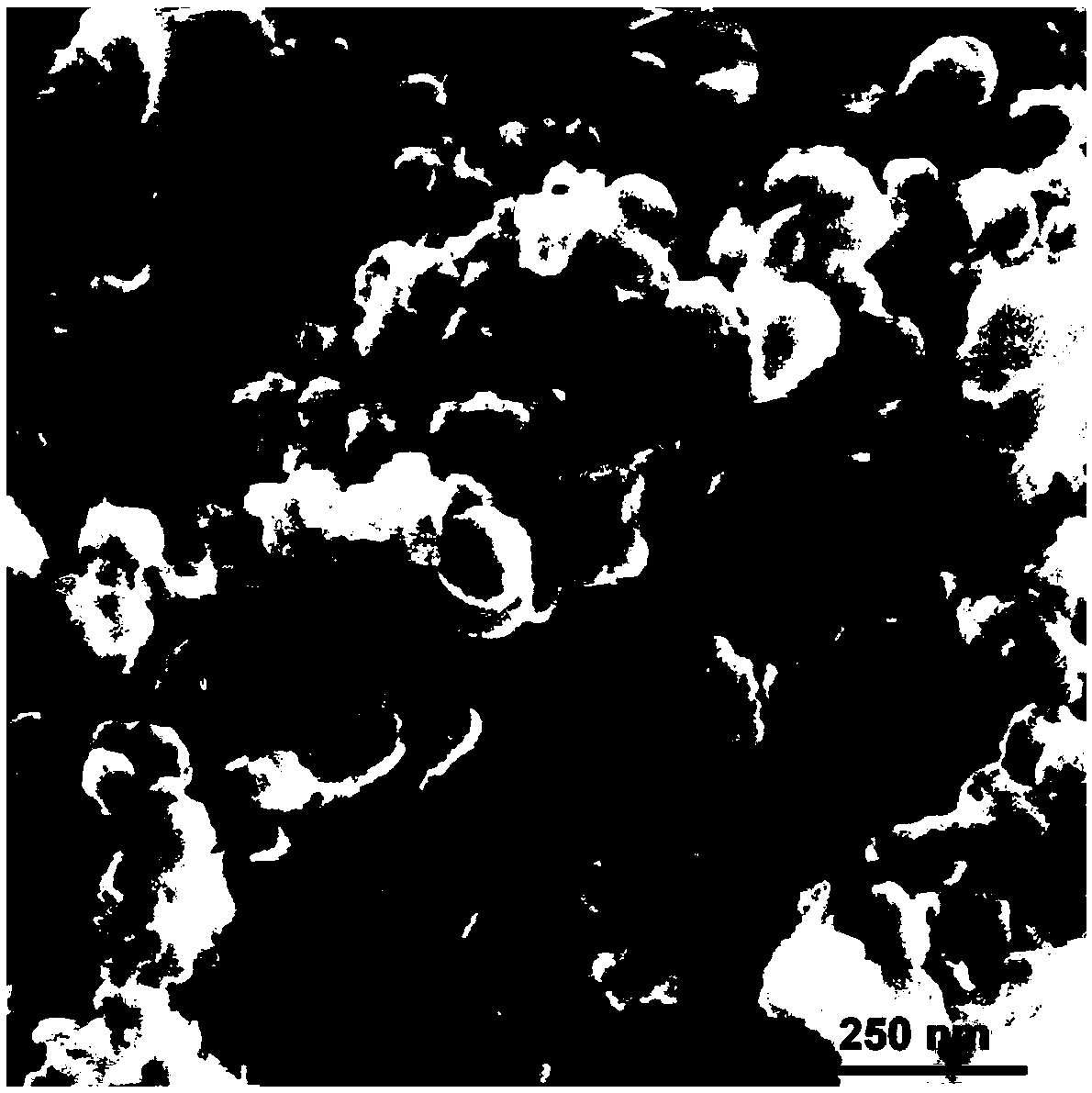

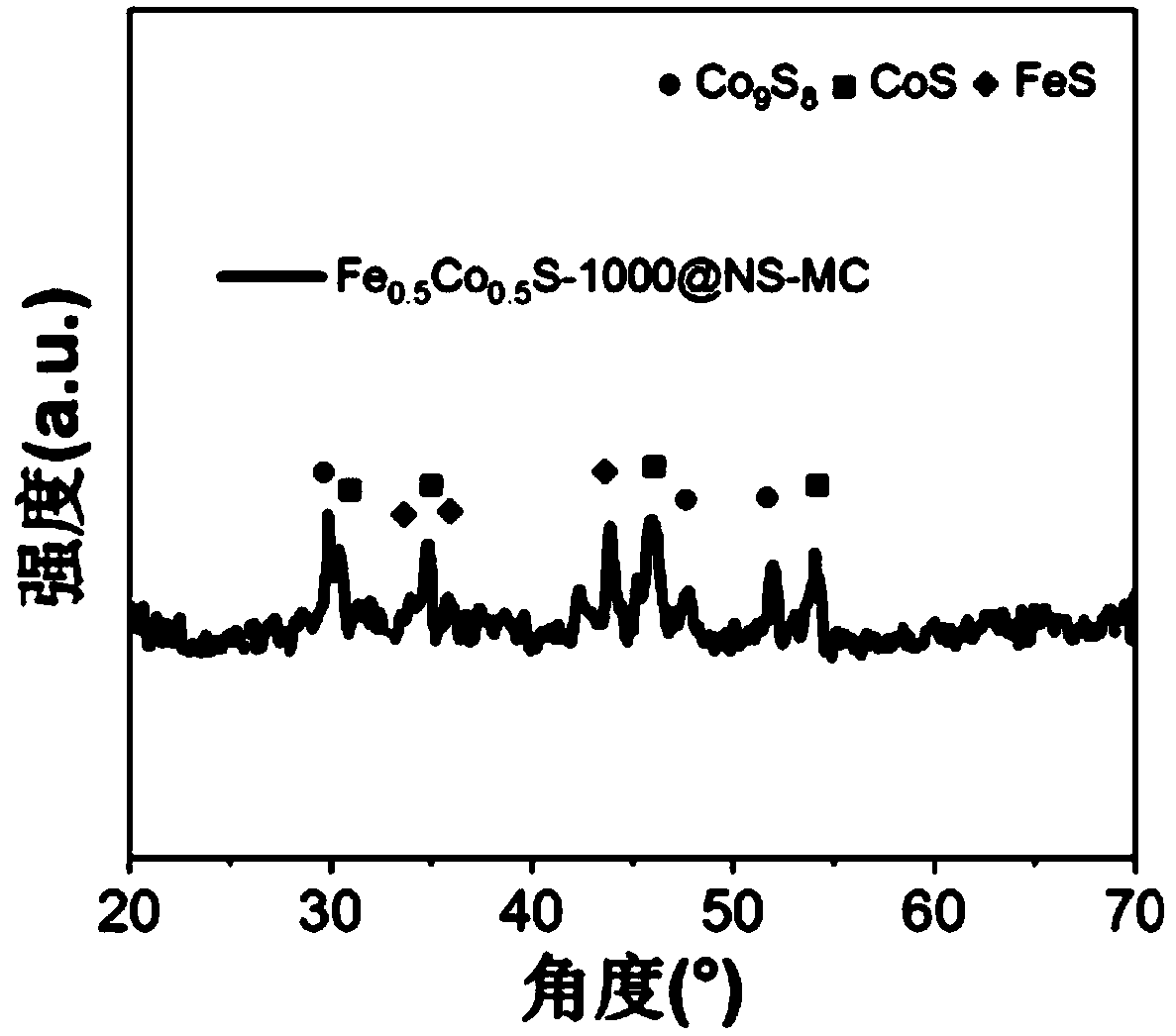

[0037] (4) The black intermediate product obtained in step (3) was placed in a tube furnace under nitrogen protection and subjected to high-temperature heat treatment at 1000° C. for 3 hours, and the heating rat...

Embodiment 2

[0040] (1) Add 0.4mL of aniline, 0.3mL of pyrrole and 0.06mL of Triton X-100 into 60mL of deionized water, and sonicate to obtain a uniform mixture;

[0041] (2) 2mmol ferric nitrate nonahydrate is added in the mixed solution in step (1), stirs to obtain new mixed solution;

[0042] (3) Add 20mL of ammonium persulfate aqueous solution with a concentration of 0.05g / mL to the mixed solution in step (2), then immediately place the mixed solution at 3°C for 24 hours of polymerization, and use the mixed solution after the polymerization reaction is completed Rotary evaporator (evaporating temperature 90°C, negative pressure inside the bottle is 0.2MPa) evaporated excess water and dried to obtain a black intermediate product;

[0043] (4) The black intermediate product obtained in step (3) was placed in a tube furnace under nitrogen protection and subjected to high-temperature heat treatment at 1000° C. for 3 hours, and the heating rate was 5° C. / min;

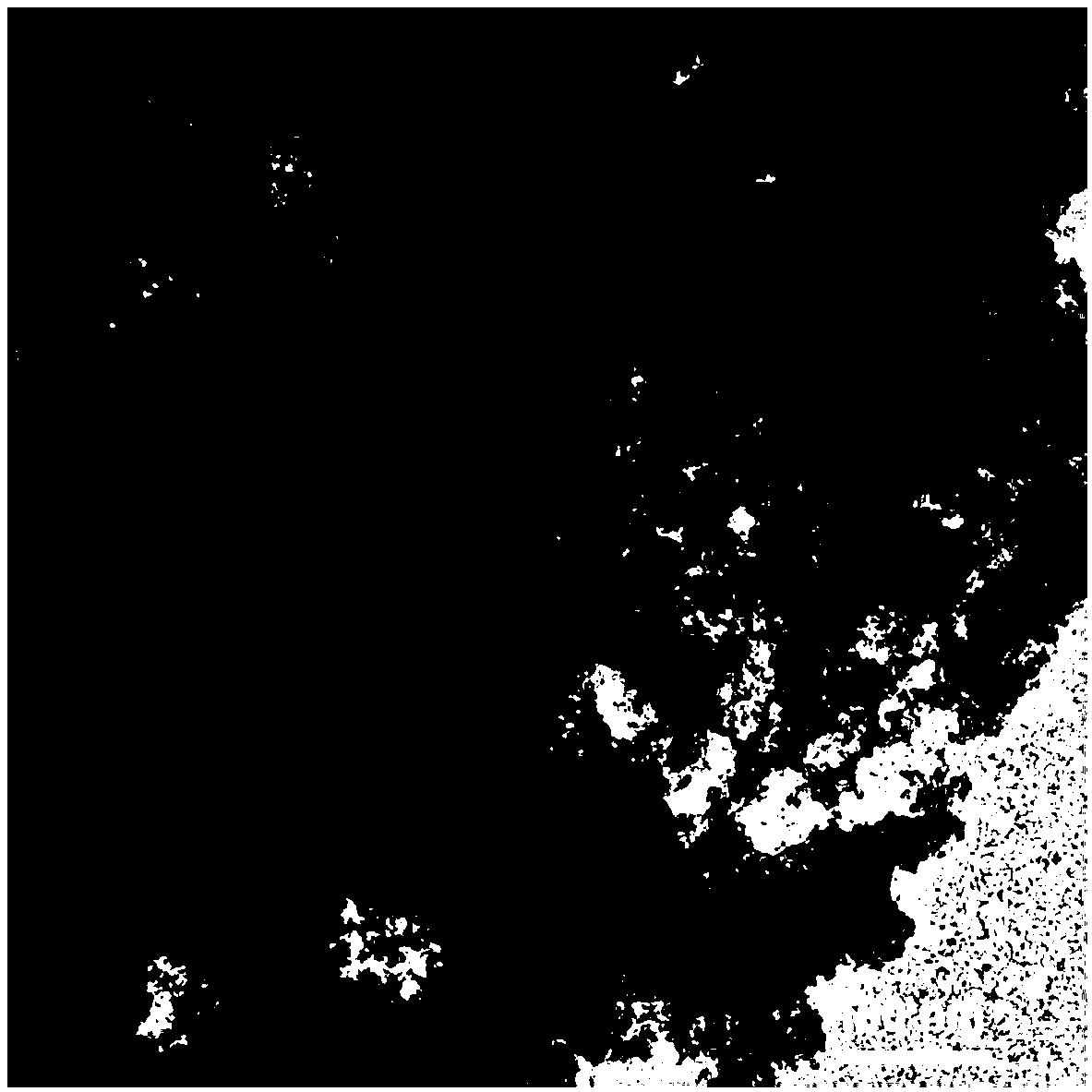

[0044] (5) The final produ...

Embodiment 3

[0046] (1) Add 0.4mL of aniline, 0.3mL of pyrrole and 0.06mL of Triton X-100 into 60mL of deionized water, and sonicate to obtain a uniform mixture;

[0047] (2) 0.5mmol ferric nitrate nonahydrate and 1.5mmol cobalt nitrate hexahydrate are added to the mixed solution in step (1), and stirred to obtain a new mixed solution;

[0048] (3) Add 20mL of ammonium persulfate aqueous solution with a concentration of 0.05g / mL to the mixed solution in step (2), then immediately place the mixed solution at 3°C for 24 hours of polymerization, and use the mixed solution after the polymerization reaction is completed Rotary evaporator (evaporating temperature 90°C, negative pressure inside the bottle is 0.2MPa) evaporated excess water and dried to obtain a black intermediate product;

[0049] (4) Place the black intermediate product obtained in step (3) under nitrogen protection in a tube furnace for high-temperature heat treatment at 1000° C. for 3 hours, with a heating rate of 5° C. / min;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com