Copper removal treatment method for waste material containing copper and selenium

A treatment method and decopper technology, which is applied in the field of copper smelting, can solve the problems of waste of resources, separation of selenium and impurities in lead filter cake, etc., and achieve the effects of improved recovery rate, stable process, and good copper leaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

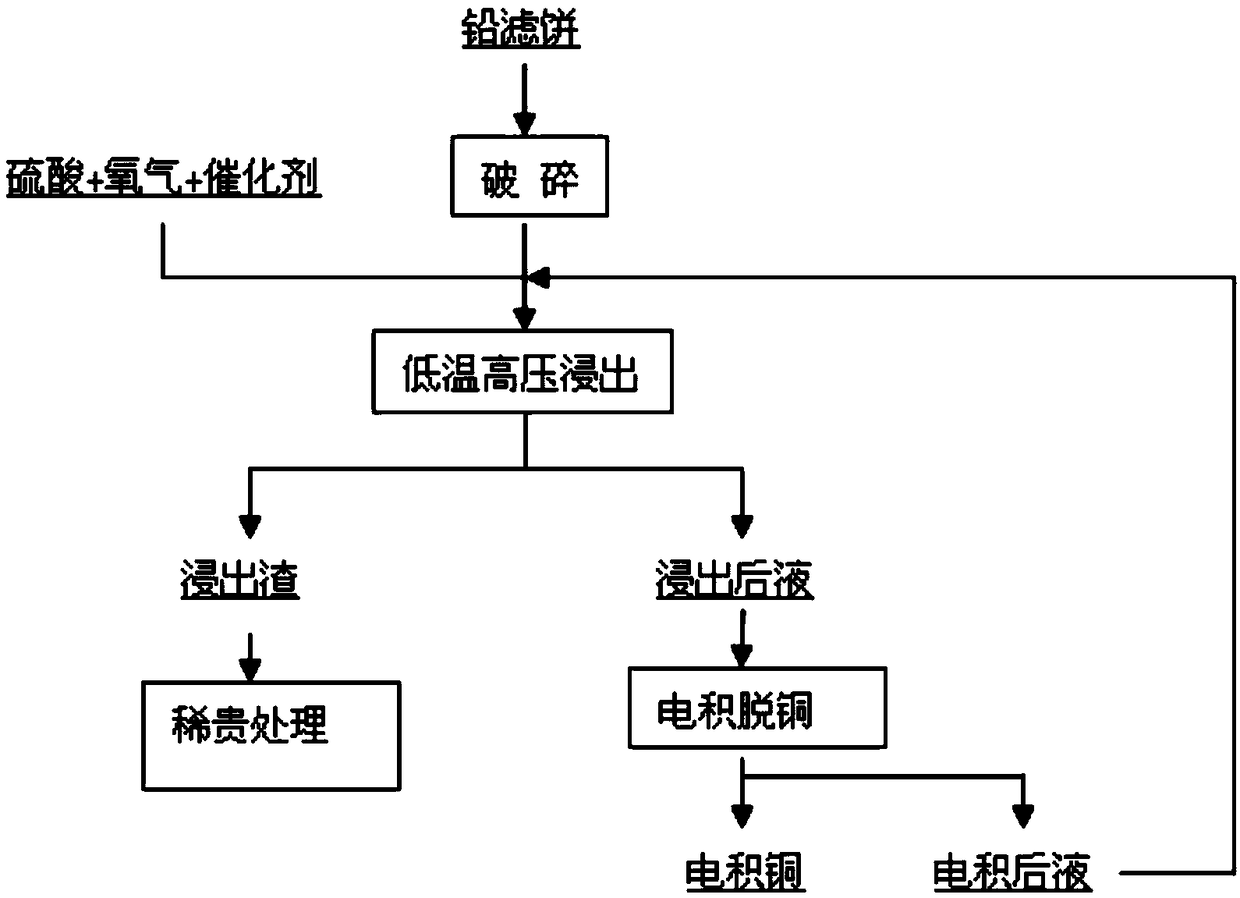

Method used

Image

Examples

Embodiment 1

[0046] 1. Pre-dipping solution

[0047] Take 4t of selenium-containing material lead filter cake, main components: Cu 16.8%, Se 27.3%, As 1%, Pb 10%, Au39g / t, Ag 1030g / t, moisture 20%; crushed to 80 mesh. First configure 19m in the reaction vessel 3 Dilute sulfuric acid solution, wherein the concentration of sulfuric acid is 220g / L. After starting the stirring, add the above-mentioned lead filter cake, and at the same time add catalyst iron powder, the addition amount is 97kg. After stirring for half an hour, pump it to the autoclave, and the pre-soaking solution is at room temperature.

[0048] 2. High pressure leaching to remove copper and pressure filtration

[0049] After the obtained prepreg mixture enters the autoclave, it is first heated to 60°C, and then oxygen is introduced to gradually increase the pressure in the reactor. When the pressure reaches 1 MPa, the oxygen supply is stopped and the pressure is maintained for 8 hours. After the reaction is completed, the pr...

Embodiment 2

[0055] 1. Pre-dipping solution

[0056] Take 3.5t of selenium-containing material lead filter cake, main components: Cu 30%, Se 45%, As 1%, Pb 15%, Au 22g / t, Ag 1350g / t, moisture 25%; crushed to 100 mesh. First configure 16m in the reaction vessel 3 Dilute sulfuric acid solution, where the concentration of sulfuric acid is 240g / L. After starting the stirring, add the above-mentioned lead filter cake, and at the same time add catalyst iron powder, the addition amount is 82kg. After stirring for half an hour, pump it to the autoclave, and the pre-dipping solution is at room temperature.

[0057] 2. High pressure leaching to remove copper and pressure filtration

[0058] After the obtained prepreg mixture enters the autoclave, it is first heated to 70°C, and then oxygen is introduced to gradually increase the pressure in the reactor. When the pressure reaches 1MPa, the oxygen supply is stopped and the pressure is maintained for 8 hours. After the reaction is completed, the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com