Solid lubricating film for aluminum alloy sheet stamping forming and preparation method thereof

An aluminum alloy sheet, stamping forming technology, applied in the direction of lubricating composition, petroleum industry, coating, etc., can solve the problem that the lubricating performance of aluminum alloy stamping is not evaluated in depth, the dispersibility of lubricant imparting agent is neglected, and the surface quality of formed parts is affected. and other problems, to achieve the effect of excellent protection ability, less residue, and excellent stamping lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Preparation of solid lubricating film

[0039] The surface of the aluminum alloy punching cup sample plate is degreased, washed and dried.

[0040] After adding the lubricating agent A and the wetting and dispersing agent C to the elastic organic coating B, add the selected diluent and defoamer, and mix by mechanical stirring. The weight percentage of each component meets the scope of the present invention. There is no special limitation on the coating method of the solid lubricant of the present invention, dipping method, spraying method and other methods can be used, and it should be noted that the coating thickness is between 5-35 microns.

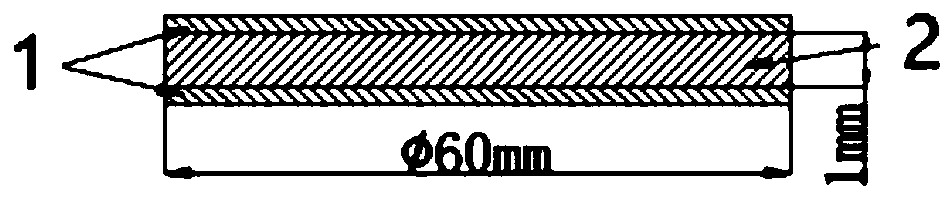

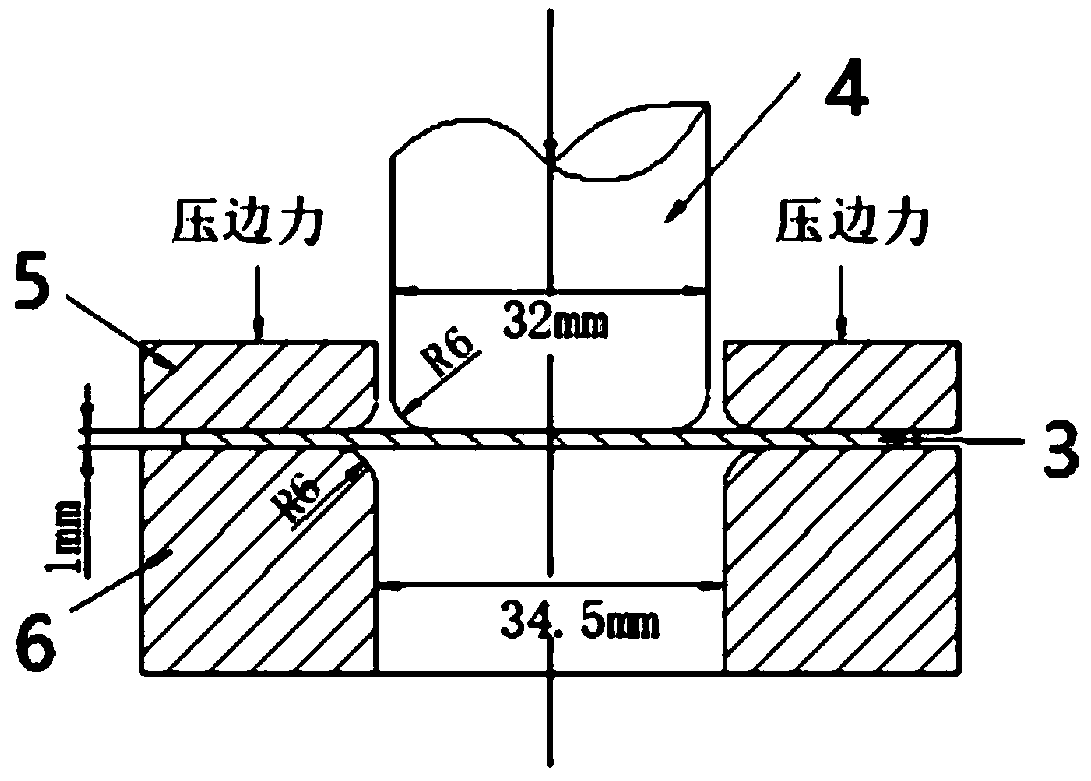

[0041] After coating, the lubricant needs to be dried and solidified. After it is surface-dried, it is cured at a temperature of 40-60°C for 4-6 hours to obtain an aluminum alloy punching cup sample coated with a solid lubricating film. figure 1 Schematic diagram of the structure of an aluminum alloy punching cup sample coated w...

Embodiment 1

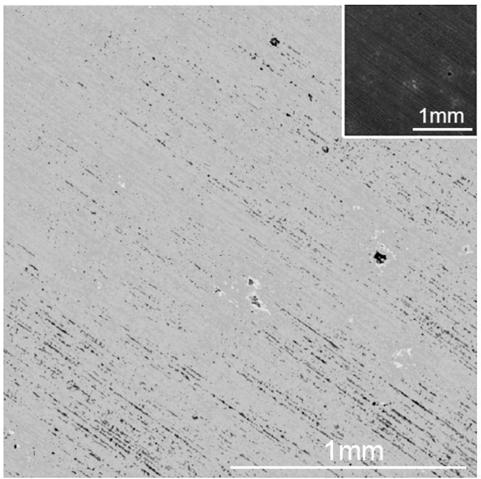

[0050]The lubricating imparting agent is selected as polytetrafluoroethylene particles with an average particle size of 2.8 microns, and the number of parts by mass is selected as 10 parts; the elastic organic coating is selected as polyurethane, and the number of parts by mass is selected as 88.5 parts; the wetting and dispersing agent is selected as Disponer904S, and the number of parts by mass is selected as 1 part, Defom 6500 is selected as the defoamer, and the mass fraction is selected as 0.5 part. The prepared solid lubricating film was coated on the same aluminum alloy disc sample as the comparative example to carry out the punching cup test. The dispersion of the lubricant imparting agent was detected by the Micromeasure2 white light confocal three-dimensional topography instrument produced by the French STIL company. The detection parameters were scanning area: 1mm×1mm; step size: 2μm×5μm; light pen depth of field: 300μm, the results are as follows image 3 As shown,...

Embodiment 2

[0054] The lubricating imparting agent is selected as polytetrafluoroethylene particles with an average particle size of 2.8 microns, and the mass parts are selected as 15 parts; the elastic organic coating is selected as polyurethane, and the mass parts are selected as 83.5 parts; the wetting and dispersing agent is selected as Disponer904S, and the mass parts are selected as 1 part, Defom 6500 is selected as the defoamer, and 0.5 parts by mass. The prepared solid lubricating film was coated on the same aluminum alloy disc sample as the comparative example to carry out the punching cup test. The dispersion of the lubricant imparting agent is detected by the Micromeasure2 white light confocal three-dimensional topography instrument produced by STIL company in France. The detection parameters are scanning area: 1mm×1mm; step size: 2μm×5μm; light pen depth of field: 300μm, the results are as follows Figure 5 As shown, the stamping pressure stroke curves of this embodiment and C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com