A kind of liquid silicone rubber impregnating solution for copper bar insulation sheath and its impregnating process

A liquid silicone rubber, processing technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., to achieve the effect of smooth surface, compactness and excellent coating effect, and solve the problem of insulation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

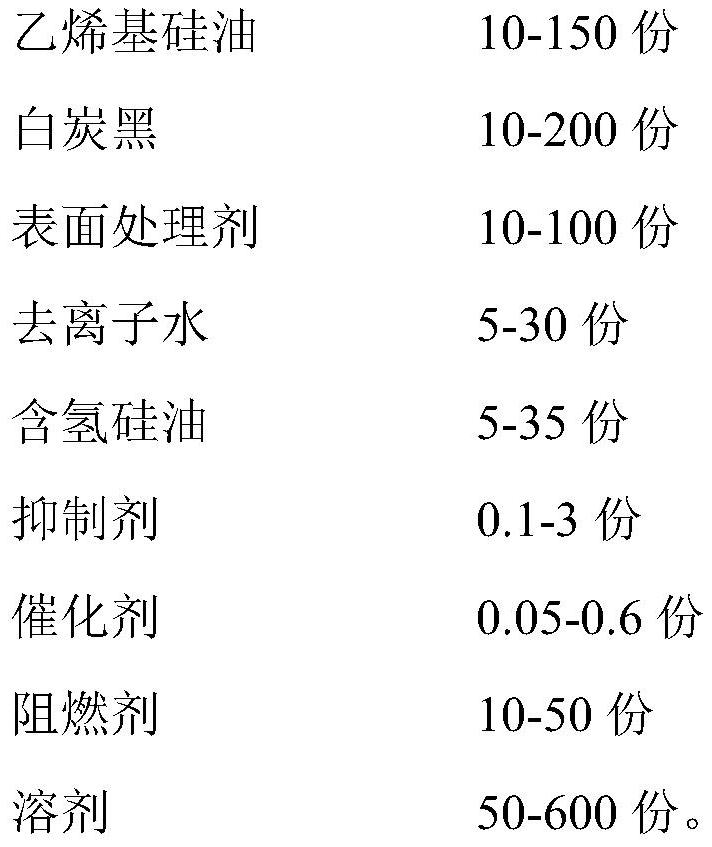

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment prepares the silicone rubber impregnation solution according to the following steps:

[0028] 1. Put 50 parts of 5000mPa·s terminal vinyl silicone oil, 50 parts of 1500mPa·s terminal vinyl silicone oil, 50 parts of 500mPa·s terminal vinyl silicone oil, 25 parts of hexamethyldisilazane and 30 parts of zinc oxide into the kneader Kneading at room temperature for 1 hour, and adding 80 parts in ten times during the kneading process 2 / g precipitated silica and 10 parts of deionized water; then raise the temperature to 80°C and knead for 1.5h; then raise the temperature to 140°C and continue kneading for 1.5h, and finally vacuumize and knead for 1h at a vacuum degree of 0.1MPa and a temperature of 140°C , cooled to room temperature to obtain the kneaded final product;

[0029] 2. Put the kneaded final product obtained in step 1 into a planetary mixer, add 450 parts of butyl acetate and stir for 2 hours, continue to add 20 parts of hydrogen-containing ...

Embodiment 2

[0038] The present embodiment prepares the silicone rubber impregnation solution according to the following steps:

[0039] 1. Mix 70 parts of 5000mPa·s terminal vinyl silicone oil, 20 parts of 1500mPa·s terminal vinyl silicone oil, 30 parts of 500mPa·s terminal vinyl silicone oil, 20 parts of hexamethyldisilazane, tetramethyltetravinyl di Put 1 part of silazane and 25 parts of zinc oxide into the kneader, knead at room temperature for 1 hour, and add 60 parts in ten times during the kneading process. 2 / g precipitated silica and 10 parts of deionized water; then raise the temperature to 80°C and knead for 1.5h; then raise the temperature to 140°C and continue kneading for 1.5h, and finally vacuumize and knead for 1h at a vacuum degree of 0.1MPa and a temperature of 140°C , cooled to room temperature to obtain the kneaded final product;

[0040] 2. Put the kneaded final product obtained in step 1 into a planetary mixer, add 500 parts of butyl acetate and stir for 2 hours, con...

Embodiment 3

[0049] The present embodiment prepares the silicone rubber impregnation solution according to the following steps:

[0050] 1. Add 30 parts of 5000mPa·s terminal vinyl silicone oil, 75 parts of 1500mPa·s terminal vinyl silicone oil, 30 parts of 500mPa·s terminal vinyl silicone oil, 25 parts of dimethyldiethoxysilane and 20 parts of magnesium hydroxide In the kneader, knead at room temperature for 1 hour, and add 75 parts of it in ten times during the kneading process 2 / g fumed silica and 15 parts of deionized water; then raise the temperature to 80°C and knead for 1.5h; then raise the temperature to 140°C and continue kneading for 1.5h, and finally vacuumize and knead for 1h at a vacuum degree of 0.1MPa and a temperature of 140°C , cooled to room temperature to obtain the kneaded final product;

[0051] 2. Put the kneaded final product obtained in step 1 into a planetary mixer, add 550 parts of cyclohexane and stir for 2 hours, continue to add 20 parts of hydrogen-containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com