Metal free-form surface polishing liquid and preparation method and application thereof

A surface polishing and free technology, applied in the field of polishing materials, can solve problems such as high cost, low product polishing efficiency, and inability to perform batch polishing, and achieve the effect of easy operation, large-scale production, and continuous polishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

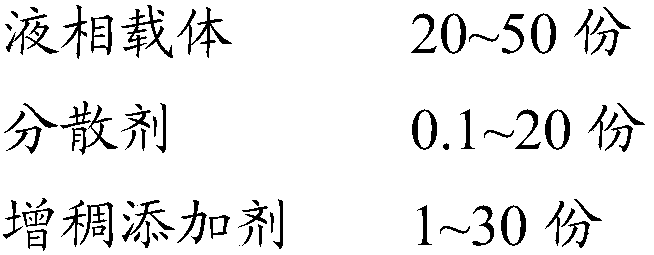

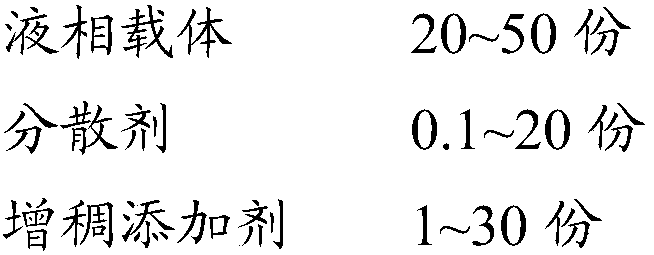

[0042] The present invention also provides a method for preparing a metal free-form surface polishing solution described in the above technical solution, comprising the following steps:

[0043] The liquid carrier, the dispersant, the friction agent, the thickening additive, the oxidizing agent and the surfactant are mixed according to the parts by weight, and the pH value is adjusted to obtain the metal free-form surface polishing liquid.

[0044] In the present invention, the mixing is preferably carried out under stirring conditions, and the stirring is preferably mechanical stirring or magnetic stirring. The present invention has no special limitation on the rotation speed and time of stirring, as long as a mixed solution can be obtained.

[0045] In the present invention, there is no special limitation on the order of adding the liquid phase carrier, dispersant, friction agent, thickening additive, oxidizing agent and surfactant; in the present invention, the mixing order ...

Embodiment 1

[0052] Weigh 5 kg of α-alumina with a particle size of 2 to 10 μm, add 1 kg of ethylene glycol (concentration: 5%), stir and disperse at room temperature, add 2.5 kg of water, 1 kg of modified ethyl cellulose, and 1 kg of 1% peroxide Hydrogen is made into a suspension, and after adding 1kgN-isopropyl polyacrylamide, a mixed solution is obtained, and the pH is adjusted to 2.5 with nitric acid solution, stirred evenly, and left to stand to obtain a metal free-form surface polishing liquid. The viscosity of the polishing liquid in a static state is 1.37 Pa.s.

[0053] Fix the 316L stainless steel frame on the fixture and immerse it in the prepared metal free-form surface polishing solution. The fixture drives the stainless steel frame to rotate rapidly around the main axis, and at the same time, the frame rotates at high speed perpendicular to the main axis, and polishes for 8 minutes to obtain a smooth mirror surface. No orange peel.

Embodiment 2

[0055] Weigh 5 kg of precipitated silica with a particle size of 20-30 μm, add 5 g of ethylene glycol solution (concentration: 10%), stir and disperse at room temperature, add 1 kg of polyethylene glycol (concentration: 70%), 50 g of corn Starch, add 50g of 0.5% hydrogen peroxide to make a suspension, add 50g of N-isopropyl polyacrylamide to obtain a mixed solution, adjust the pH to 3 with nitric acid solution, stir evenly, and let it stand to obtain a metal free-form surface polishing Liquid, the viscosity of the polishing liquid at rest is 1.52Pa.s.

[0056] The 316L stainless steel frame is fixed on the jig and immersed in the prepared metal free-form surface polishing solution. The jig drives the stainless steel frame to rotate rapidly around the main shaft. Orange peel phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com