Alkaline titanium sol color-fixing agent and preparation method and application thereof

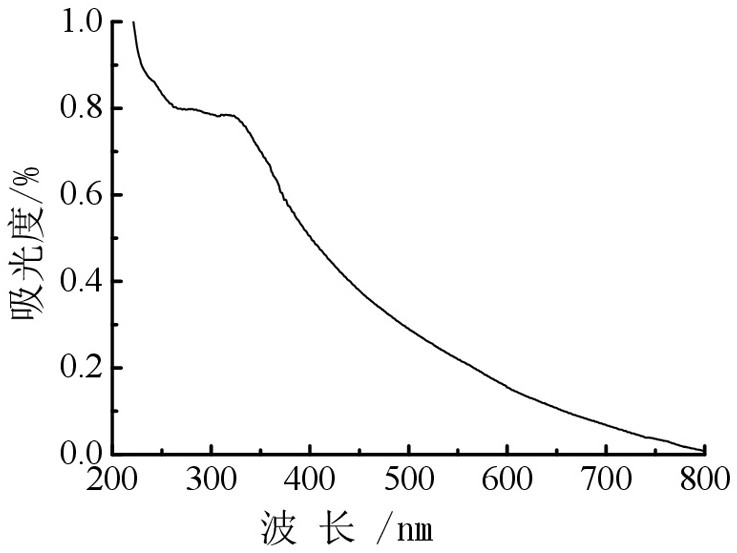

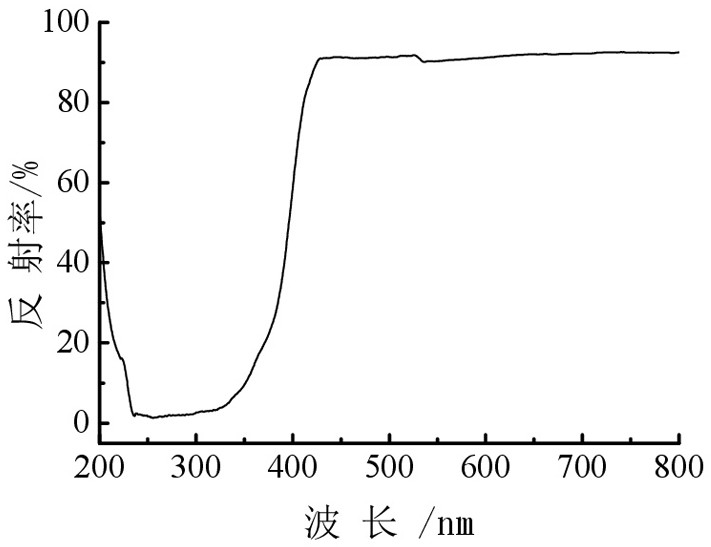

A technology of titanium sol and color fixing agent, which is applied in the field of alkaline titanium sol color fixing agent and its preparation, can solve the problem that the color fastness to light has not been effectively improved, the color fixing rate and color fastness have not been greatly improved, and the printing and dyeing process has become more serious. The difficulty of biological treatment of wastewater and other issues, to achieve good ultraviolet light absorption performance, improve dyeing rate and fixation rate, and promote the effect of adsorption and dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the alkaline titanium sol of the present invention specifically comprises the following steps:

[0035] (1) Mix 34g of butyl titanate, 26.3g of diethanolamine and 64.4g of absolute ethanol, stir evenly, and prepare solution A.

[0036] (2) Mix 21.6g of distilled water and 32.2g of absolute ethanol evenly to prepare solution B.

[0037] (3) Take solution A and put it into the reactor, heat it up to 60 °C at a heating rate of 2 °C / min, start the stirrer in the reactor, and control the stirring speed to be 500 rpm / min; add solution B at a dropping speed of 1 mL / min It was slowly added dropwise to the reactor, condensed and refluxed, and after 2 hours of reaction, 0.2 g of γ-aminopropyl ethoxysilane was added dropwise, and the reaction was continued to stir for 1 hour, and allowed to stand for 12 hours to obtain a milky white alkaline titanium sol solid. Toner.

[0038] The viscosity of the alkaline titanium sol color-fixing agent in this embodim...

Embodiment 2

[0044] The invention relates to the application of an alkaline titanium sol color-fixing agent in the field of wood dyeing.

[0045] The alkaline titanium sol fixing agent and soda ash of Example 1 were compared, and the fixing effect of reactive dyes on wood dyeing was investigated:

[0046] Reactive red X-3B dye solution, reactive red M-3BE dye solution, reactive blue X-BR dye solution, reactive blue M-2GE dye solution, reactive yellow X-R dye solution, reactive Yellow M-3RE dye solution; add 40g / L yuanming powder to each dye solution, dye poplar veneer (size 100×50×2mm) at constant temperature of 1:20 at 80°C for 3h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com