Bacteria-resistant polyphenylene ether and nylon alloy material and preparation method thereof

A technology of alloy material and polyphenylene ether, which is applied in the field of antibacterial polyphenylene ether and nylon alloy materials and their preparation, can solve the problems of no performance, etc., and achieve the goal of overcoming poor processing performance, good bacteria resistance and high impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

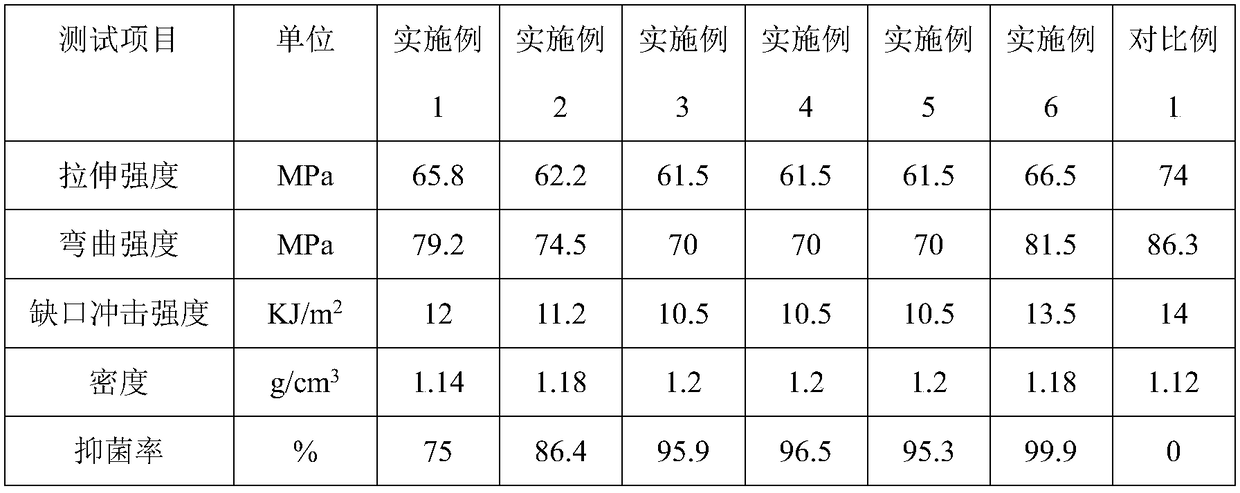

Examples

preparation example Construction

[0019] The preparation method of antibacterial polyphenylene ether and nylon alloy material:

[0020] 1): Weigh the raw materials polyphenylene ether resin, nylon resin, compatibilizer, toughening agent, silver ion antibacterial agent and antioxidant according to the weight ratio, put the weighed raw materials into the high-speed mixer and mix them thoroughly for 3~ 5 minutes;

[0021] 2): The material obtained in step (1) is fed into the twin-screw extruder through the main feeder, and melted and extruded by the twin-screw extruder. The extrusion process is: twin-screw extruder temperature zone: twin-screw extruder Extruder temperature zone: zone 1 temperature 160℃~190℃, zone 2 temperature 200℃~230℃, zone 3 temperature 230℃~260℃, zone 4 temperature 230℃~260℃, zone 5 temperature 230℃~260℃ , The temperature of the sixth zone is 240℃~270℃, the temperature of the seventh zone is 240℃~270℃, the temperature of the eighth zone is 240℃~270℃, the temperature of the ninth zone is 240℃...

Embodiment 1

[0024] 1): Weigh 60 parts of polyphenylene ether resin and 21.7 parts of nylon resin according to the weight ratio, and dry them in an oven; add 3 parts of compatibilizer, 10 parts of toughening agent, 5 parts of silver ion antibacterial agent, antioxidant Mix 0.3 parts of the agent in a high-speed mixer for 3 to 5 minutes;

[0025] 2): The material obtained in step (1) is fed into the twin-screw extruder through the main feeder, and melted and extruded by the twin-screw extruder. The extrusion process is: twin-screw extruder temperature zone: twin-screw extruder Extruder temperature zone: zone 1 temperature 160℃~190℃, zone 2 temperature 200℃~230℃, zone 3 temperature 230℃~260℃, zone 4 temperature 230℃~260℃, zone 5 temperature 230℃~260℃ , The temperature of the sixth zone is 240℃~270℃, the temperature of the seventh zone is 240℃~270℃, the temperature of the eighth zone is 240℃~270℃, the temperature of the ninth zone is 240℃~270℃, the temperature of the head is 250℃~280℃, the sc...

Embodiment 2

[0028] 1): Take 50 parts of polyphenylene ether resin and 26.7 parts of nylon resin according to the weight ratio, and dry them in an oven; add 5 parts of compatibilizer, 10 parts of toughening agent, 8 parts of silver ion antibacterial agent, anti-oxidant Mix 0.3 parts of the agent in a high-speed mixer for 3 to 5 minutes;

[0029] 2): The material obtained in step (1) is fed into the twin-screw extruder through the main feeder, and melted and extruded by the twin-screw extruder. The extrusion process is: twin-screw extruder temperature zone: twin-screw extruder Extruder temperature zone: zone 1 temperature 160℃~190℃, zone 2 temperature 200℃~230℃, zone 3 temperature 230℃~260℃, zone 4 temperature 230℃~260℃, zone 5 temperature 230℃~260℃ , The temperature of the sixth zone is 240℃~270℃, the temperature of the seventh zone is 240℃~270℃, the temperature of the eighth zone is 240℃~270℃, the temperature of the ninth zone is 240℃~270℃, the temperature of the head is 250℃~280℃, the sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com