Carbon nanotube surface modification method

A technology of carbon nanotubes and surface modification, applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve problems such as broken tube walls, defects, and difficult disposal of waste liquid, and achieve stable dispersion and improved compatibility , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

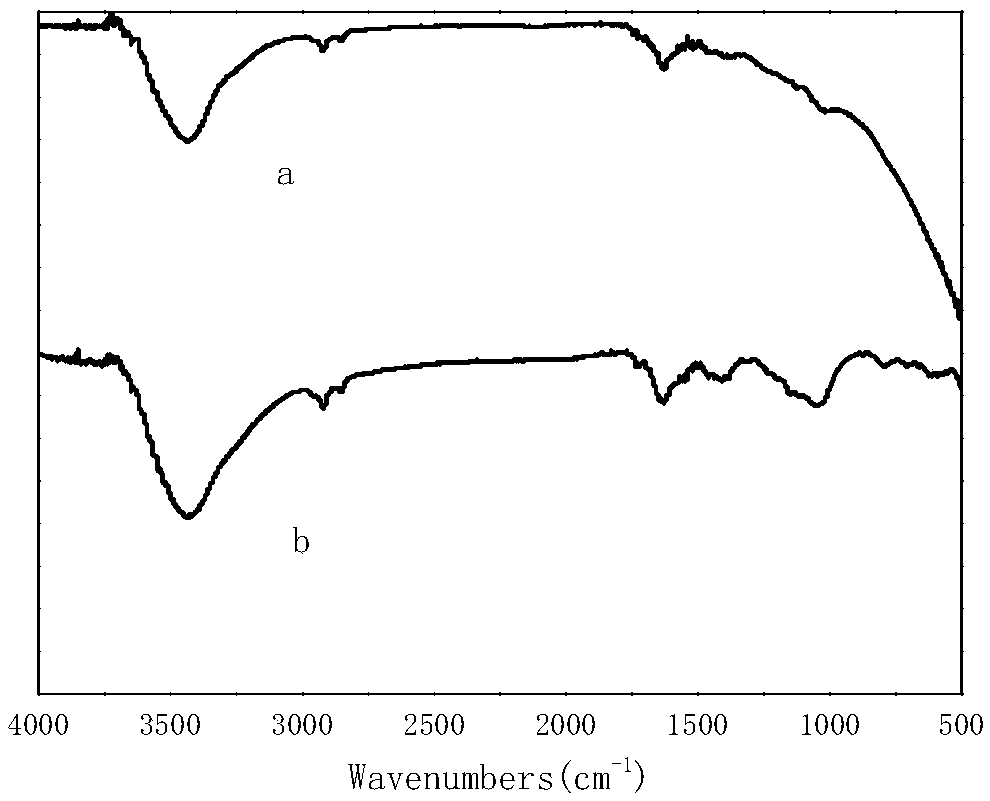

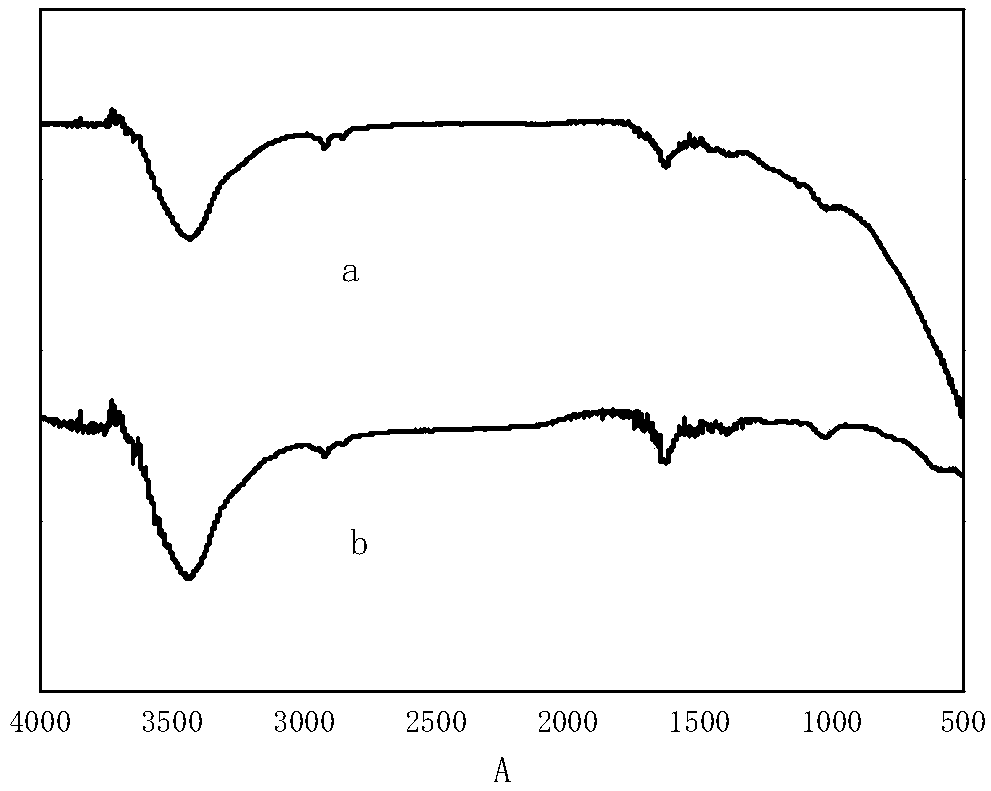

Method used

Image

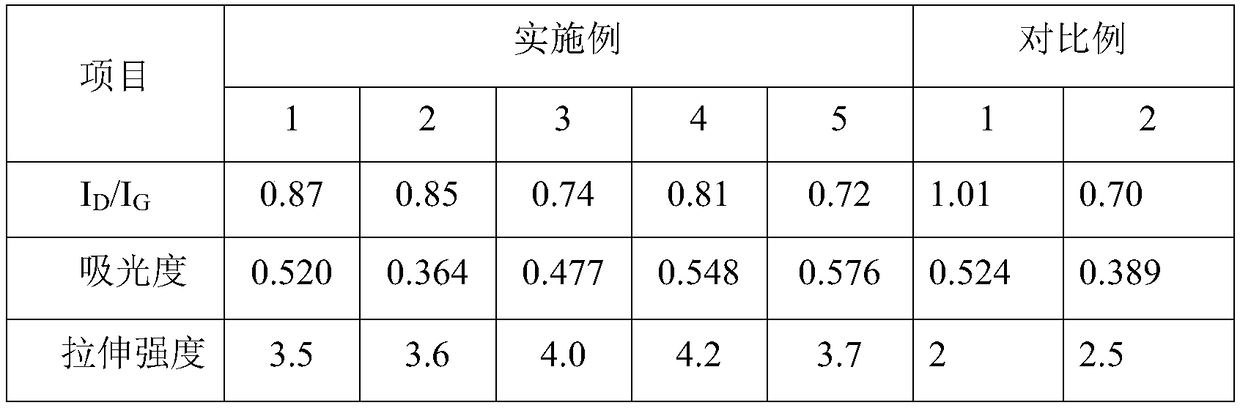

Examples

Embodiment 1

[0033] (1) the first step purification treatment of carbon nanotubes: 10ml concentration is that the ferrous sulfate solution of 1mol / L is mixed with the hydrogen peroxide solution of 30wt% with 12ml concentration, obtains the hydrogen peroxide solution containing ferrous sulfate catalyst, Adjust pH=2; put 0.1g of untreated carbon nanotubes into a hydrogen peroxide solution containing ferrous sulfate catalyst, react under ultrasonic vibration conditions for 4 hours, centrifuge to separate carbon nanotubes, and use deionized water to filter Wash until neutral, then dry in a vacuum oven;

[0034] (2) Carry out the second step of purification treatment on the carbon nanotubes treated in step (1): place 0.1 g of the treated carbon nanotubes in a muffle furnace for 3 hours and roast in an air atmosphere, and the roasting temperature is 400° C.;

[0035] (3) Coating the carbon nanotubes treated in step (2) with polydopamine: the tris of 0.788g and 14.7ml of concentration are mixed e...

Embodiment 2

[0038] (1) The first step purification treatment of carbon nanotubes: the ferrous sulfate solution that is 0.5mol / L is mixed with the hydrogen peroxide solution that 10ml concentration is 30wt% by 8ml concentration, obtains the hydrogen peroxide solution that contains ferrous sulfate catalyst , adjust the pH=4; put 0.1g of untreated carbon nanotubes into the hydrogen peroxide solution containing ferrous sulfate catalyst, react for 5 hours under the condition of ultrasonic vibration, centrifuge the carbon nanotubes, use deionized water to pump Filter and wash until neutral, then dry in a vacuum oven;

[0039] (2) Carrying out the second step of purification treatment on the carbon nanotubes treated in step (1): placing 0.1 g of the treated carbon nanotubes in a muffle furnace for 2 hours of roasting, the atmosphere is air atmosphere, and the roasting temperature is 350° C.;

[0040] (3) Coating the carbon nanotubes treated in step (2) with polydopamine: the tris of 0.788g and 1...

Embodiment 3

[0043] (1) The first step purification treatment of carbon nanotubes: 12ml concentration is that the ferrous sulfate solution of 1.5mol / L is mixed with the hydrogen peroxide solution of 20wt% with 8ml concentration, obtains the hydrogen peroxide solution containing ferrous sulfate catalyst , adjust the pH=3; put 0.1g of untreated carbon nanotubes into the hydrogen peroxide solution containing ferrous sulfate catalyst, react for 4 hours under the condition of ultrasonic vibration, centrifuge the carbon nanotubes, use deionized water to pump Filter and wash until neutral, then dry in a vacuum oven;

[0044] (2) Carry out the second step of purification treatment on the carbon nanotubes treated in step (1): place 0.1 g of the treated carbon nanotubes in a muffle furnace and roast for 1 hour, the atmosphere is an air atmosphere, and the roasting temperature is 450° C.;

[0045] (3) Coating the carbon nanotubes treated in step (2) with polydopamine: the tris of 0.788g and 16.7ml of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com