Detection method for bottom morphology of phase defect in multilayer film with extreme ultraviolet lithography mask

A technology of extreme ultraviolet lithography and multi-layer film, applied in micro-lithography exposure equipment, optics, opto-mechanical equipment, etc. The effect of moving, eliminating detection errors, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment, but should not limit protection scope of the present invention with this embodiment.

[0033] Specific steps are as follows:

[0034] Step 1. Set the defect bottom morphology parameters of the blank mask containing multilayer film phase defects in the training set:

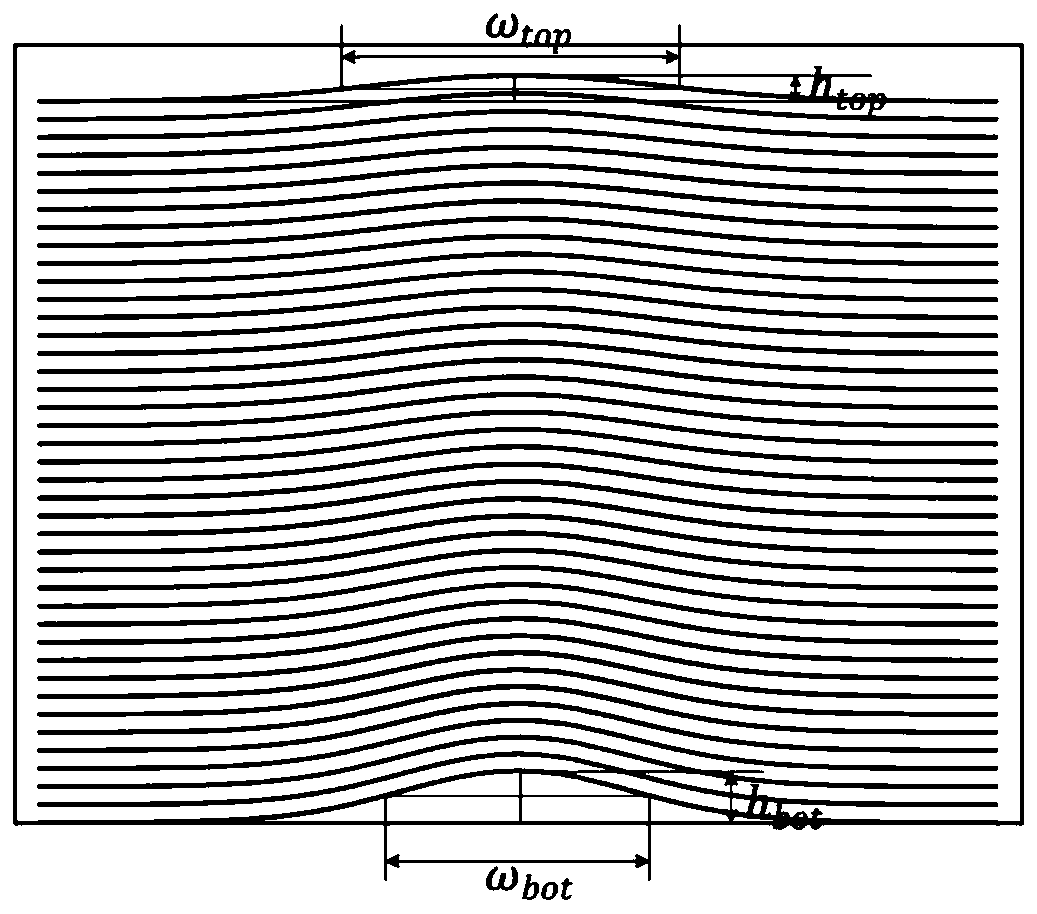

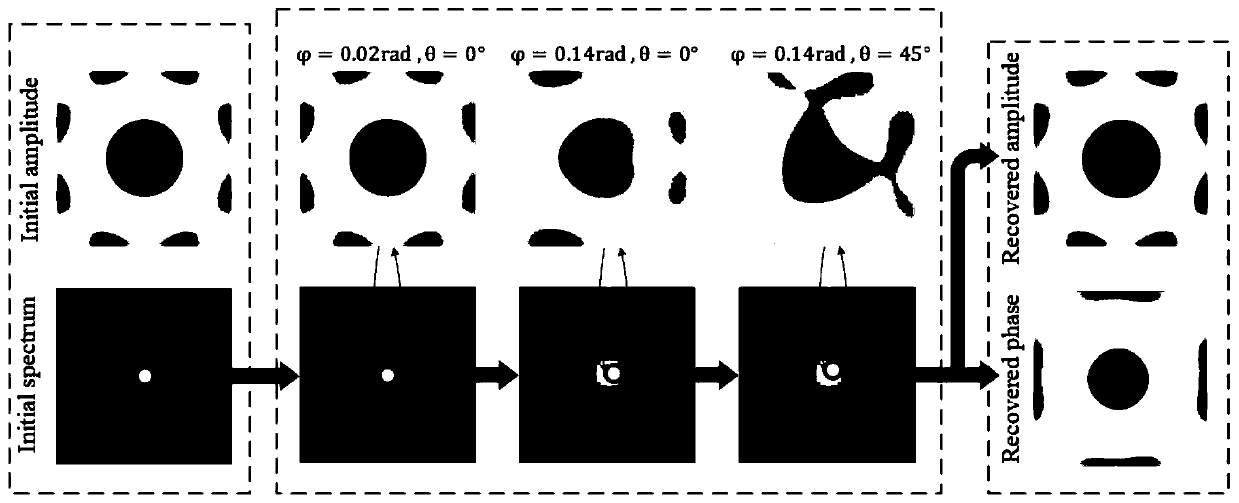

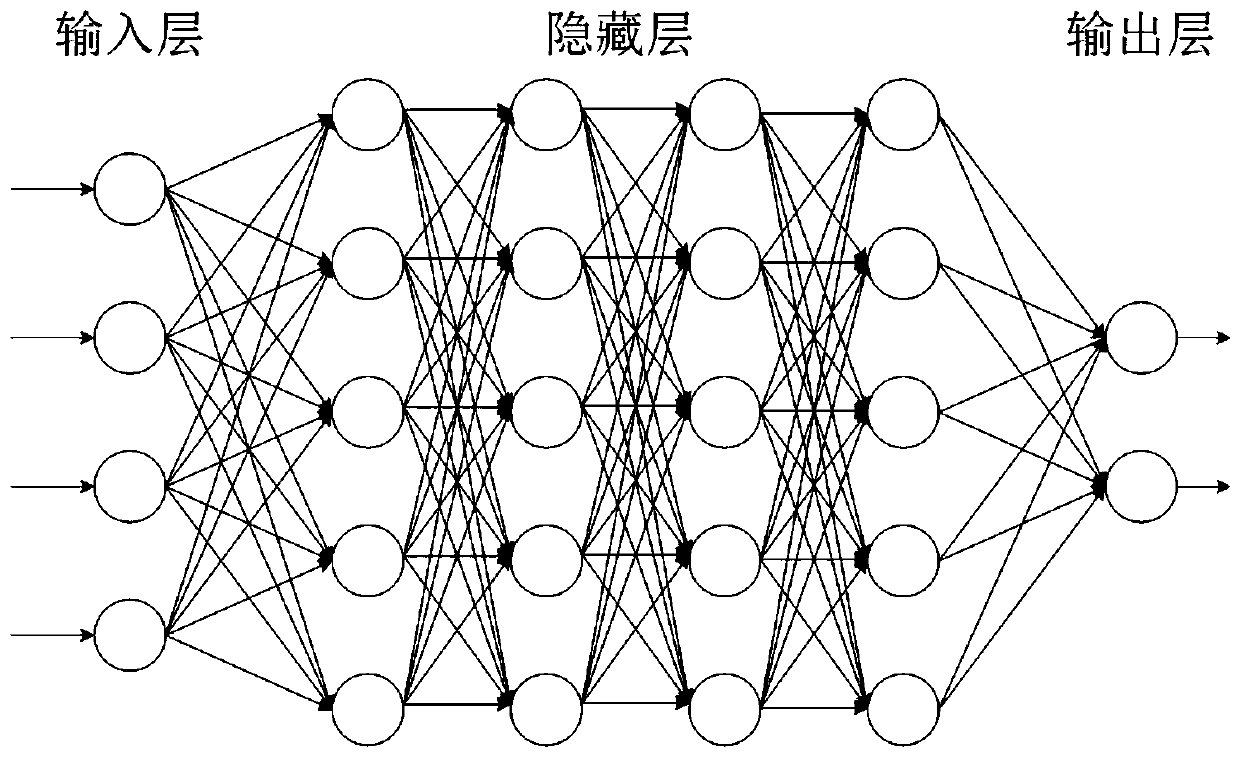

[0035] The morphology of phase defects in the multilayer film of the mask is characterized by Gaussian defect parameters, and the full width at half maximum of the defect surface is ω top , with height h top , the full width at half maximum at the bottom of the defect is ω bot , with height h bot , the structure of the EUV lithography mask containing phase defect multilayer film is as follows figure 1 shown. Since the surface topography of phase-type defects in the multilayer film of the mask can be better detected by existing instruments, the surface topography can be set as a known parameter. In this example, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com