A non-ironing finishing process of polyester-cotton white fabric

A non-iron finishing and fabric technology, applied in the processing of textile materials, fabric, fabric surface trimming, etc., can solve the problems of time-consuming transfer, affecting the cycle of non-iron finishing, etc., to shorten the processing cycle, excellent anti-wrinkle effect, Comfortable and comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

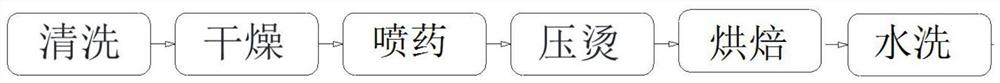

[0046] Take a fabric with a warp and weft yarn count of 80 English strands and a warp and weft density of 130*90 threads / inch as an example. The fabric is woven from 20% polyester and 80% cotton blended yarn. The non-ironing finishing method includes: The following steps:

[0047] Cleaning: wash the cotton fabric with water to remove organic and inorganic impurities on the surface of the cotton fabric;

[0048] Drying: dry the cleaned cotton fabric at 55°C for 25 minutes;

[0049] Spraying: Spray the finishing liquid on the dried cotton fabric in the injection device, so that the surface of the cotton fabric is evenly liquid-filled. The finishing liquid includes the following components and the mass concentrations of each component are: polyethylene emulsion 30g / L; polyurethane 25g / L; urea 5g / L; amino acid oil 35 / L; Water-based silicone softener 8g / L; catalyst 16g / L; penetrant 1g / L; dimethylol urea resin 160g / L; fluorescent agent: 2.5g / L; the balance is water;

[0050] Pres...

Embodiment 2

[0055] Take a fabric with warp and weft counts of 100 strands and a warp and weft density of 130*90 strands / inch as an example. The fabric is woven from 20% polyester and 80% cotton blended yarn. The non-ironing finishing method includes: The following steps:

[0056] Cleaning: wash the cotton fabric with water to remove organic and inorganic impurities on the surface of the cotton fabric;

[0057] Drying: Dry the cleaned cotton fabric at 50°C for 30 minutes;

[0058] Spraying: Spray the finishing liquid on the dried cotton fabric in the injection device, so that the surface of the cotton fabric is evenly liquid-filled. The finishing liquid includes the following components and the mass concentrations of each component are: polyethylene emulsion 33g / L; polyurethane 25.5g / L; urea 5.5g / L; amino acid oil 36 / L ; Hydrophilic silicone softener 8.5g / L; catalyst 15.5g / L; penetrating agent 1g / L; dimethylol urea resin 155g / L; fluorescent agent: 2g / L; the balance is water;

[0059] Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com