Compound preparation method of high-performance rare earth magnesium alloy

A rare-earth magnesium, high-performance technology, applied in the processing of high-performance wrought magnesium alloys, and the composite preparation of high-performance wrought magnesium alloys, can solve the problem of fine and dense recrystallization structure, the improvement of the plastic deformation ability of magnesium alloys is not significant, and has not yet been discovered. Satisfy the problems of dispersion and precipitation, achieve the effect of improving processing stability, improving dynamic precipitation effect, and avoiding thermal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following, ZK60-1Yb deformed magnesium alloy is used as an example material, and the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

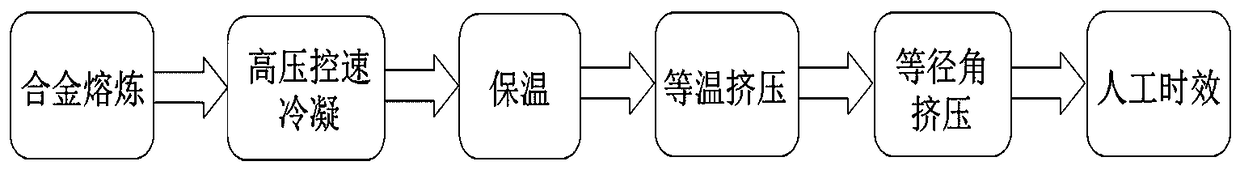

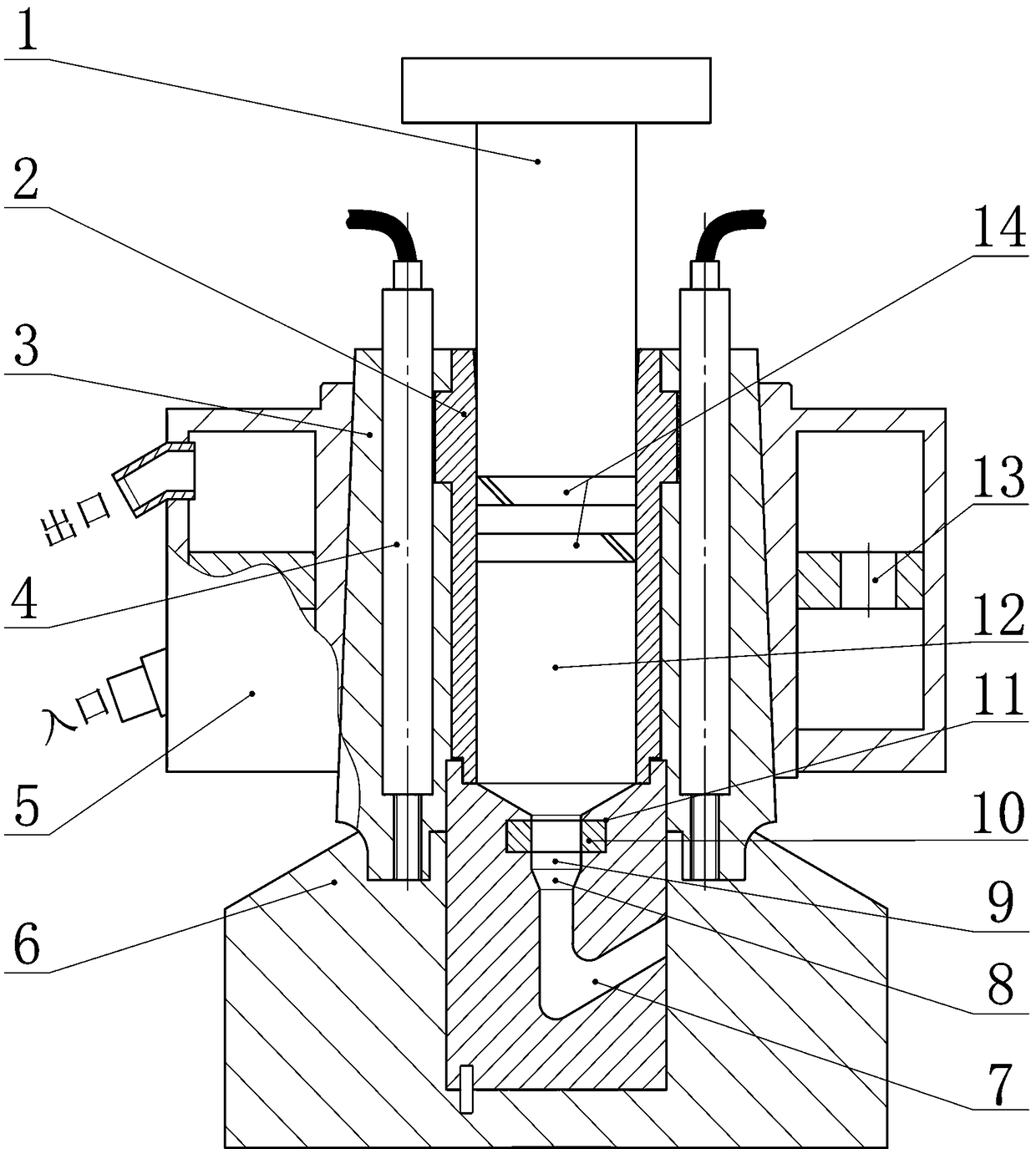

[0030] When this method is actually implemented, through such as figure 1 The process flow shown and figure 2The mold structure shown realizes the composite preparation of ZK60-1Yb high-performance magnesium alloy, and its functions integrate gold melting, high specific pressure controlled speed condensation, shrinking extrusion and equal diameter angular extrusion processing; including sequentially connected cavities 12. Extrusion cavity 9, reduced-diameter extrusion belt 8 and equal-diameter angular extrusion cavity 7; wherein the upper end of the cavity 12 is arranged with a punch 1 with an elastic sealing ring 14, and the lower end of the cavity 9 is extruded There is a movable plate 10 inside, which transitionally cooperates with the socket 11 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com