Bacterium-inhibiting cleaning solution for underpants and production and manufacturing method thereof

A technology for cleaning liquid and underwear, which is applied to chemical instruments and methods, detergent compositions, detergent compounding agents, etc. It can solve the problem of general cleaning effect and bactericidal effect, difficult to completely remove harmful chemicals, and inability to rinse off liquid foam and other problems, to achieve good cleaning effect, excellent degreasing and degreasing effect, good water solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

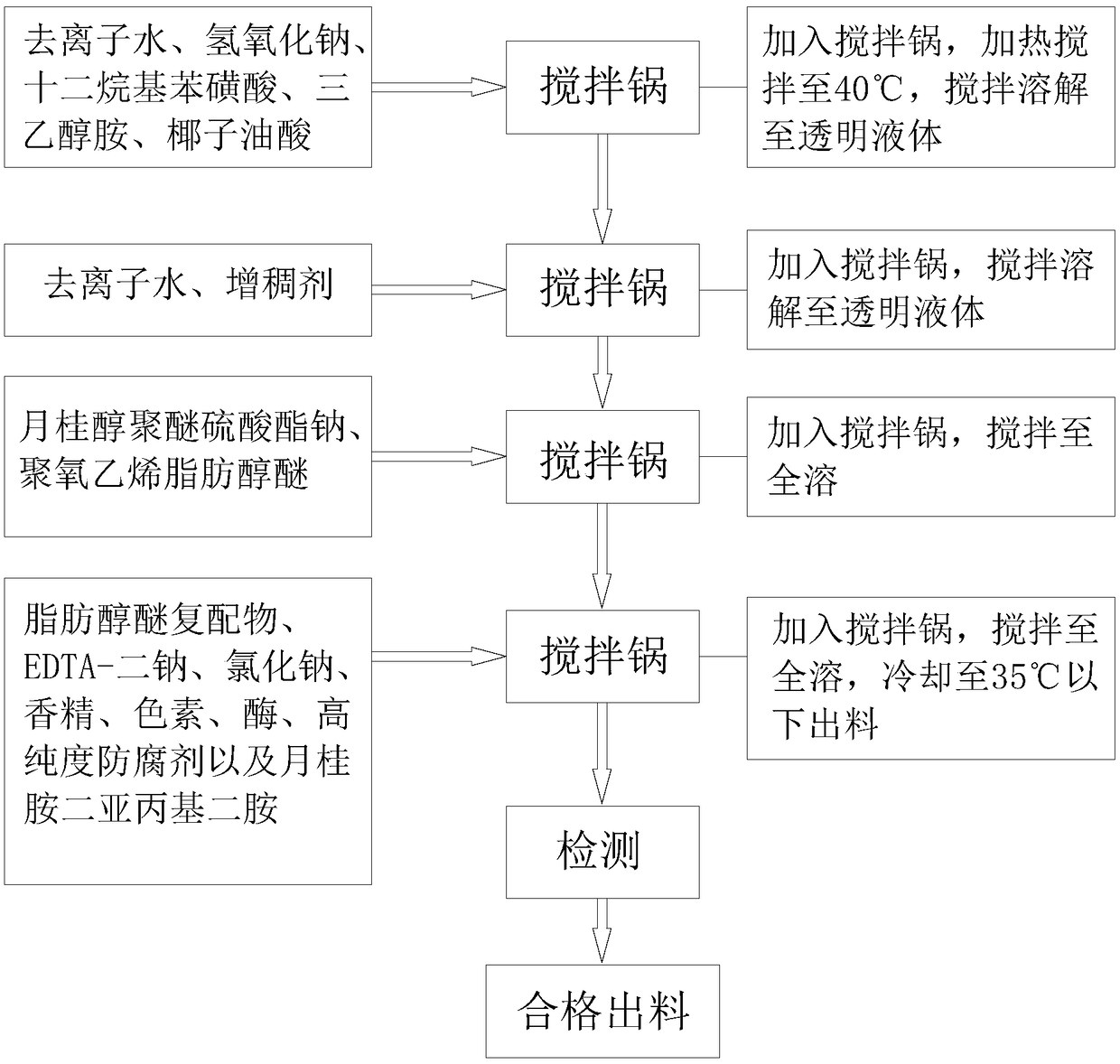

Method used

Image

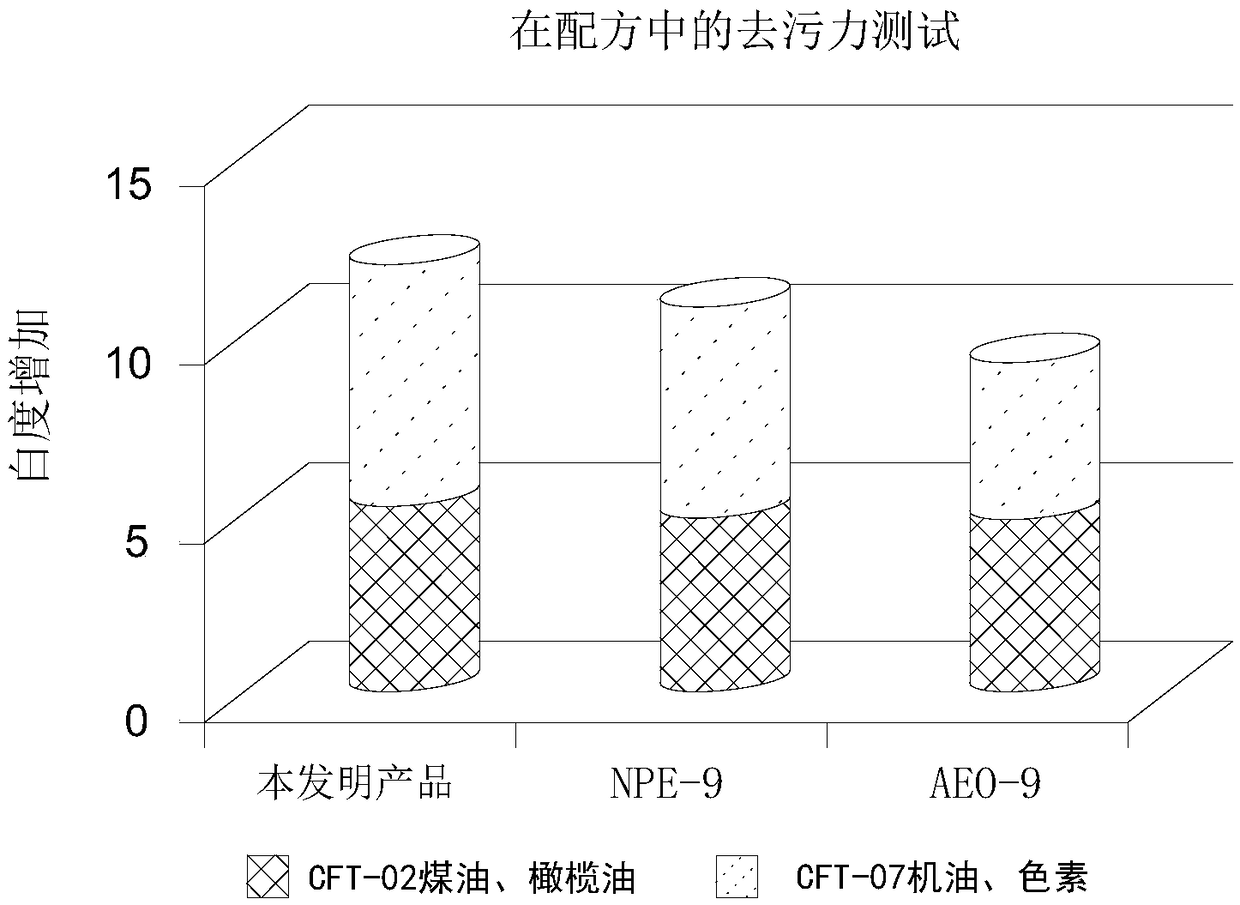

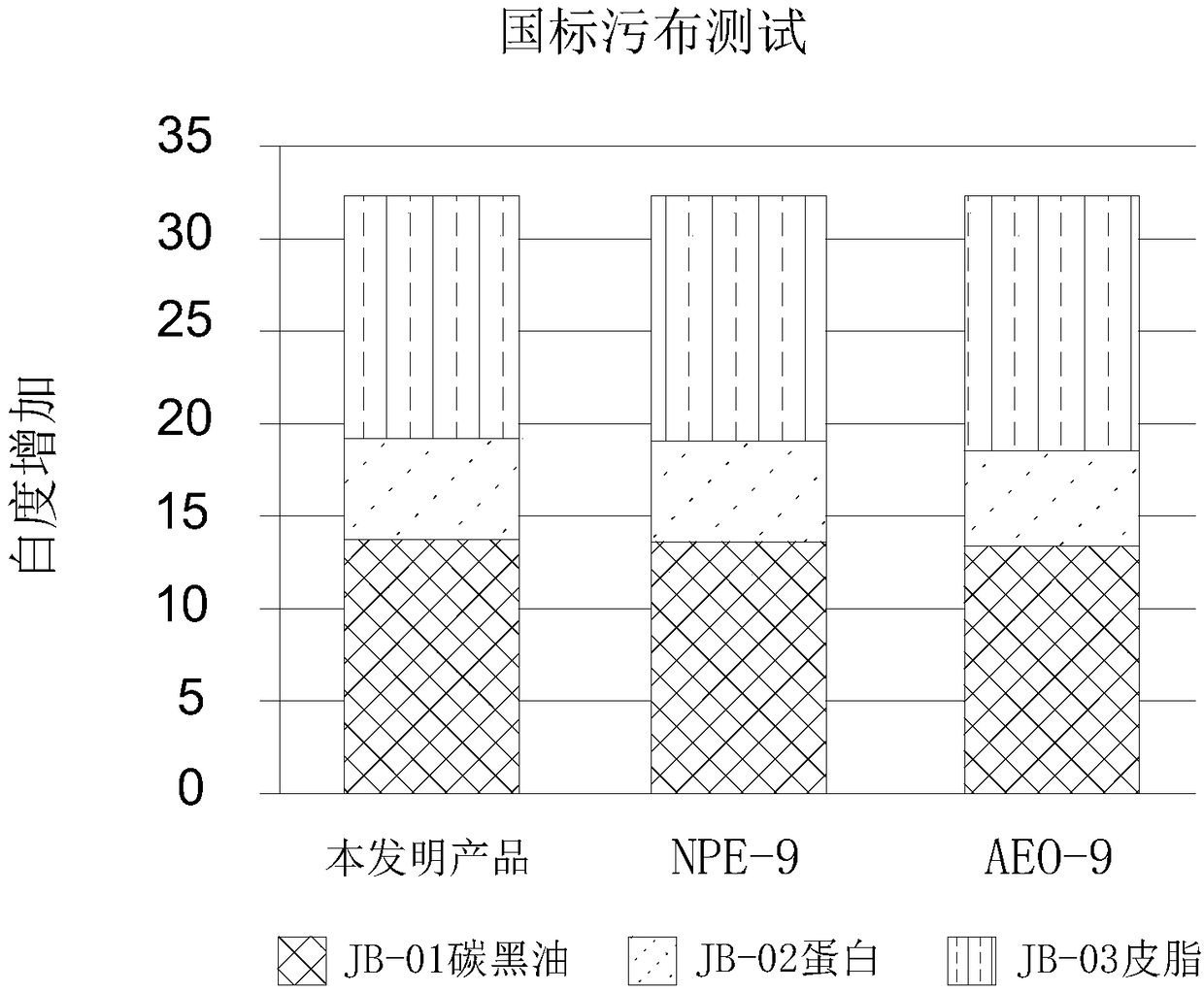

Examples

Embodiment 1

[0028] An antibacterial cleaning solution for underwear, which is prepared by the following specific components in parts by mass: 40 parts of deionized water, 15 parts of dodecylbenzenesulfonic acid, and sodium hydroxide solution with a mass fraction of 40-55% 4 parts, 3 parts of triethanolamine, 5 parts of coconut oleic acid, 1 part of thickener, 0.7 parts of sodium laureth sulfate, 3 parts of polyoxyethylene fatty alcohol ether, 1 part of fatty alcohol ether compound, EDTA- 0.8 part of disodium, 2 parts of sodium chloride, 0.8 part of essence, 0.6 part of pigment, 0.1 part of enzyme, 0.4 part of high-purity preservative, 0.5 part of laurylamine dipropylenediamine (Triameen Y12D).

[0029] Wherein, the thickener is HC-200 thickener, the polyoxyethylene fatty alcohol ether is AEO-9 polyoxyethylene fatty alcohol ether, and the high-purity antiseptic is Kathon-CG high-purity antiseptic agent.

[0030] The fatty alcohol ether compound adopts two or more mixtures of polyoxyethyle...

Embodiment 2

[0040] An antibacterial cleaning solution for underwear, which is prepared by the following specific components in parts by mass: 50 parts of deionized water, 20 parts of dodecylbenzenesulfonic acid, and sodium hydroxide solution with a mass fraction of 40-55% 6 parts, 6 parts of triethanolamine, 10 parts of coconut oleic acid, 2 parts of thickener, 1.1 parts of sodium laureth sulfate, 5 parts of polyoxyethylene fatty alcohol ether, 1.4 parts of fatty alcohol ether compound, EDTA- 1.3 parts of disodium, 3 parts of sodium chloride, 1.2 parts of essence, 0.9 parts of pigment, 0.4 parts of enzyme, 0.6 part of high-purity preservative, 0.7 part of laurylamine dipropylene diamine (Triameen Y12D).

[0041] Wherein, the thickener is HC-200 thickener, the polyoxyethylene fatty alcohol ether is AEO-9 polyoxyethylene fatty alcohol ether, and the high-purity antiseptic is Kathon-CG high-purity antiseptic agent.

[0042]The fatty alcohol ether compound adopts two or more mixtures of poly...

Embodiment 3

[0052] An antibacterial cleaning solution for underwear, which is prepared by the following specific components in parts by mass: 47 parts of deionized water, 18 parts of dodecylbenzenesulfonic acid, and sodium hydroxide solution with a mass fraction of 40-55% 5 parts, 5 parts of triethanolamine, 8 parts of coconut oleic acid, 1.5 parts of thickener, 0.9 parts of sodium laureth sulfate, 4 parts of polyoxyethylene fatty alcohol ether, 1.3 parts of fatty alcohol ether compound, EDTA- 0.9 parts of disodium, 2.6 parts of sodium chloride, 1.1 parts of essence, 0.8 parts of pigment, 0.2 parts of enzyme, 0.5 parts of high-purity preservative, and 0.6 parts of laurylamine dipropylenediamine (Triameen Y12D).

[0053] Wherein, the thickener is HC-200 thickener, the polyoxyethylene fatty alcohol ether is AEO-9 polyoxyethylene fatty alcohol ether, and the high-purity antiseptic is Kathon-CG high-purity antiseptic agent.

[0054] The fatty alcohol ether compound adopts two or more mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com