Anti-bacterial and flame-retardant PVC composite board and processing method thereof

A composite board and PVC resin technology, which is applied in the field of wood-plastic composite materials, can solve the problems of low mechanical strength of PVC board, poor adhesion between the matrix and filler interface, etc., and achieves low cost, improved compatibility, and good application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

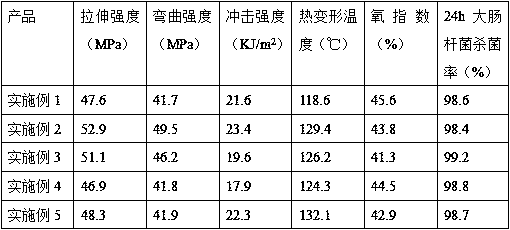

Examples

Embodiment 1

[0035] An antibacterial and flame-retardant PVC composite board, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 8 parts of acrylic acid-maleic anhydride copolymer, 55 parts of wood powder, 50 parts of modified calcium carbonate, 6 parts of shell powder, nitrogen 4 parts of boron compound, 2.5 parts of aramid fiber, 3 parts of foaming agent, 1.5 parts of flame retardant, 1 part of antibacterial agent, 2.5 parts of plasticizer, 1.5 parts of organotin stabilizer, 1 part of 1010 antioxidant, modified 3 parts of agent and 4 parts of processing aid.

[0036]The modifier is composed of octaaminophenyl clathrate silsesquioxane and rapeseed fatty acid alkanolamide borate with a mass ratio of 2:1. The foaming agent is composed of AC foaming agent and triterpene saponin with a mass ratio of 2:1. The flame retardant is composed of zinc borate and polyaminopropylmethylsilsesquioxane with a mass ratio of 2:1. The antibacterial agent is composed of chito...

Embodiment 2

[0047] An antibacterial and flame-retardant PVC composite board, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 6 parts of acrylic acid-maleic anhydride copolymer, 45 parts of wood powder, 55 parts of modified calcium carbonate, 8 parts of shell powder, nitrogen 5 parts of boron compound, 1.5 parts of aramid fiber, 3.5 parts of foaming agent, 1 part of flame retardant, 1.5 parts of antibacterial agent, 3 parts of plasticizer, 0.5 part of organotin stabilizer, 0.8 part of 1076 antioxidant, modified 2.5 parts of agent and 3 parts of processing aid.

[0048] The modifier is composed of octaaminophenyl clathrate silsesquioxane and rapeseed fatty acid alkanolamide borate with a mass ratio of 1.5:1. The foaming agent is composed of AC foaming agent and triterpene saponin with a mass ratio of 1:1. The flame retardant is composed of zinc borate and polyaminopropylmethylsilsesquioxane with a mass ratio of 1:1. The antibacterial agent is composed of...

Embodiment 3

[0059] An antibacterial and flame-retardant PVC composite board, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 10 parts of acrylic acid-maleic anhydride copolymer, 60 parts of wood powder, 50 parts of modified calcium carbonate, 5 parts of shell powder, nitrogen 3.5 parts of boron compound, 2.5 parts of aramid fiber, 4 parts of foaming agent, 2 parts of flame retardant, 2 parts of antibacterial agent, 1.5 parts of plasticizer, 1.5 parts of calcium zinc stabilizer, 1.5 parts of CA antioxidant, modified 4 parts of agent and 4 parts of processing aid.

[0060] The modifier is composed of octaaminophenyl clathrate silsesquioxane and rapeseed fatty acid alkanolamide borate with a mass ratio of 3:1. The foaming agent is composed of AC foaming agent and triterpene saponin with a mass ratio of 2:1. The flame retardant is composed of zinc borate and polyaminopropylmethylsilsesquioxane with a mass ratio of 1:1. The antibacterial agent is composed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com