A kind of silicone type polyurethane damping material and preparation method thereof

A damping material, polyurethane technology, applied in the field of organic polymer material synthesis, can solve problems such as low elastic modulus and unsuitable damping materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

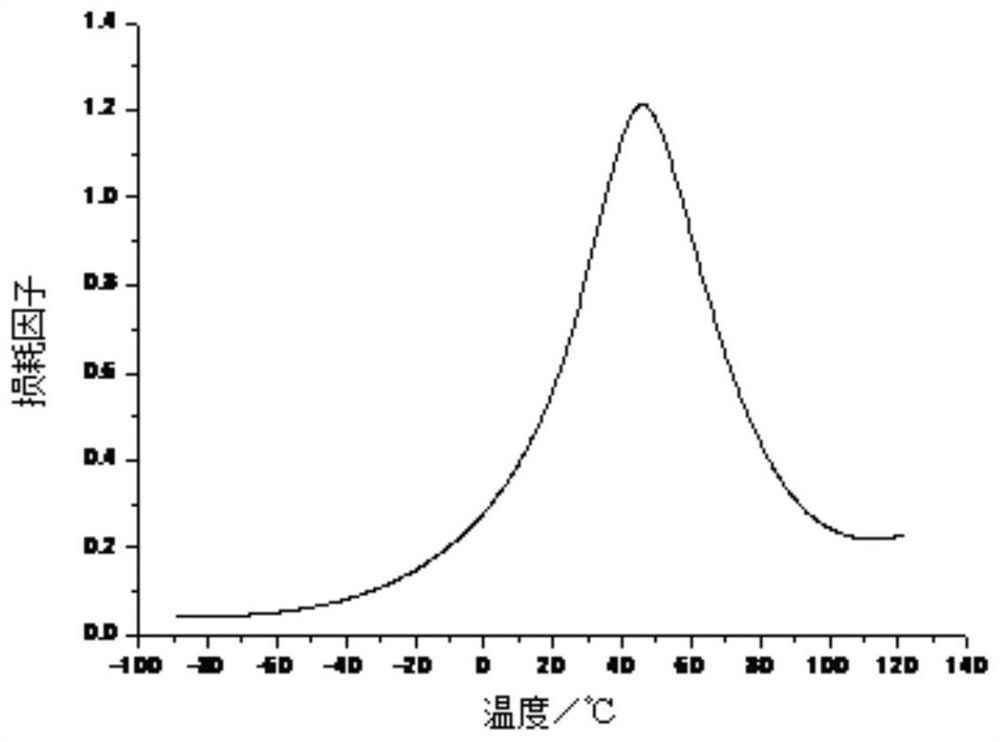

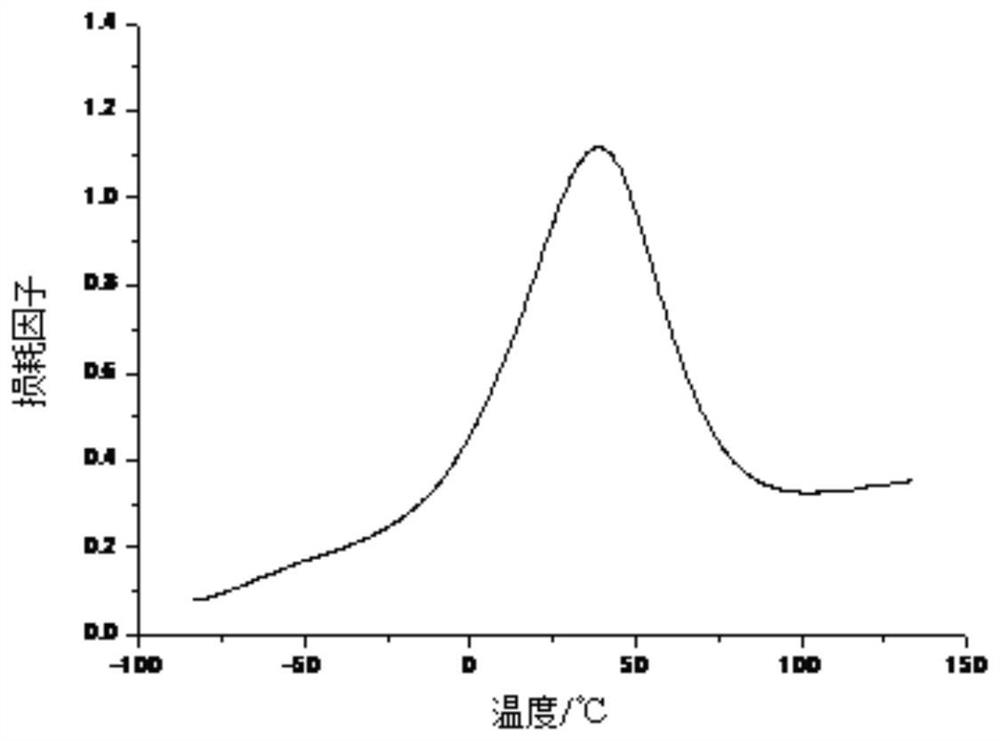

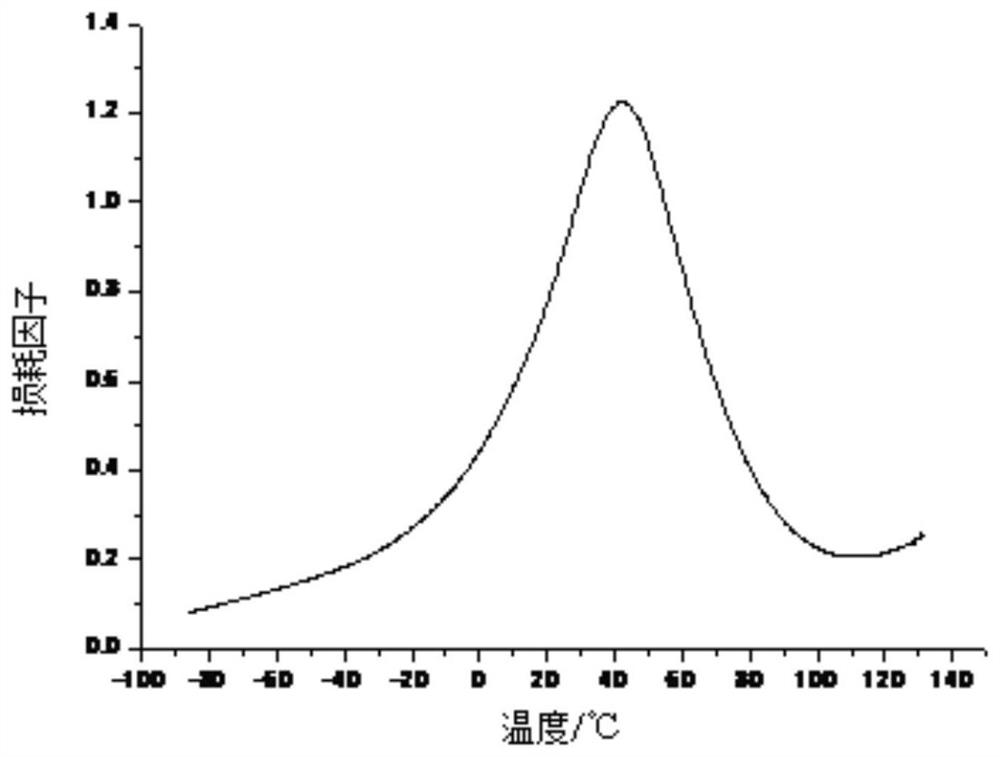

Image

Examples

Embodiment 1

[0033] 1) Synthesis of terminal alkenyl ether alcohols:

[0034] Add 116.16g of allyl alcohol and 4g of KOH into a 2L stainless steel autoclave, vacuumize for 10 minutes, fill with nitrogen for 5 minutes, then repeat the vacuum and nitrogen filling twice, then vacuumize, heat up to 110°C, and add the measured Methyl propylene oxide 576.8g, the feeding time of the feeding pump is 2h, the pressure in the reactor is controlled not to exceed 0.7MPa, after the feeding is completed, the reaction temperature is controlled at 110-115°C, and the reaction is 5h. After there is no pressure in the reactor, keep warm After 0.5 h, the temperature was lowered to 70° C. and vacuum was applied for 1 h, the temperature was lowered and the material was filtered to obtain 679.1 g of light yellow terminal alkenyl ether alcohol with a yield of 98%.

[0035] 2) Synthesis of diols with the same carbon dimethyl structure and the same silicon dimethyl structure:

[0036] Add 141.16g of terminal hydrog...

Embodiment 2

[0040]In the step 3) the diisocyanate added in the preparation process of silicone polyurethane damping material is IPDI, the addition amount is 44.7g, the chain extender is MDBA, the dosage is 36.4g, and the rest are the same as in Example 1. The tensile strength, brittleness temperature, loss factor and damping temperature range of the obtained damping material are listed in Table 1.

Embodiment 3

[0042] Said step 3) the preparation process of organosilicon polyurethane damping material, add said step 2) 20g of diol synthesized, polytetrahydrofuran diol (molecular weight 1000) 20g, TDI addition is 41.1g, chain extender is MDBA , Add-on 39.5g, all the other are with embodiment 1. The tensile strength, brittleness temperature, loss factor and damping temperature range of the obtained damping material are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com