High-damping resin-based friction material and preparation method thereof

A friction material and resin-based technology, applied in the field of friction materials, can solve the problems of the influence of the mechanical properties of composite materials, the difficulty of controlling the uniformity of materials, and the complicated preparation process, so as to improve the ride comfort, the friction coefficient is stable, and the friction coefficient is high. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

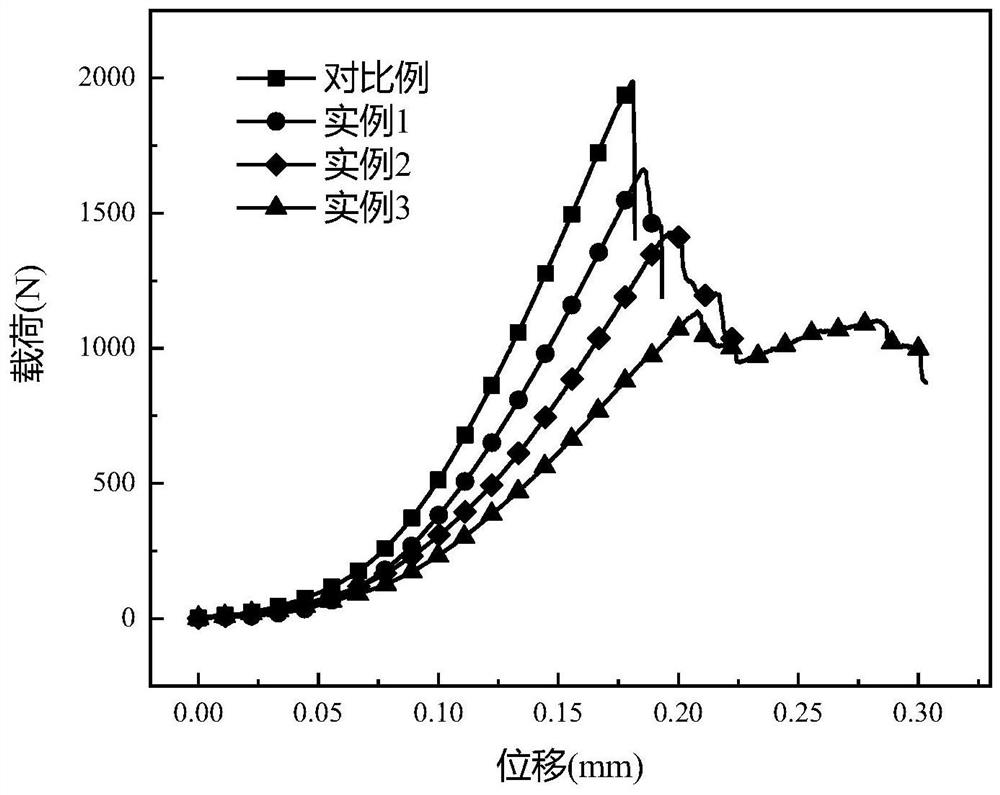

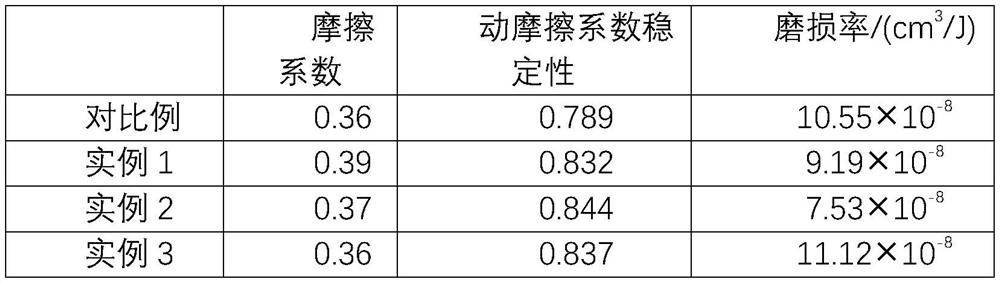

example 1

[0032] A high-damping resin-based friction material, comprising the following components according to mass percentage: phenolic resin: 13%-18%, polyacrylonitrile carbon fiber: 15%-20%, friction performance regulator: 40%-60%, damping silicon Rubber content: 3% to 6%.

[0033] Step 1: weigh phenolic resin, fiber, friction performance modifier and damping silicone rubber according to mass percentage, put into high-speed mixer and stir, and put into mold after reaching uniform mixing;

[0034] Step 2: Preheating the die to 150-160°C, ready for pressing;

[0035] Step 3: the pressing process conditions are: pressing temperature 160°C, pressing pressure 5Mpa, heat preservation and pressure holding time 600s, deflation once every 50 seconds;

[0036] Step 4: Put the pressed product sample in an oven, raise the temperature to 120°C, and keep it warm for 60 minutes; raise the temperature to 140° C, and keep it warm for 90 minutes; raise the temperature to 160° C, and keep it warm for...

example 2

[0038] A high-damping resin-based friction material, comprising the following components according to mass percentage: phenolic resin: 13%-18%, polyacrylonitrile carbon fiber: 15%-20%, friction performance modifier: 40%-55%, damping silicon Rubber content: 9% to 12%; the preparation method of the material is as described in Example 1.

example 3

[0040] A high-damping resin-based friction material, comprising the following components according to mass percentage: phenolic resin: 13%-18%, polyacrylonitrile carbon fiber: 15%-20%, friction performance modifier: 40%-50%, damping silicon Rubber content: 13% to 16%; the preparation method of the material is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com