Method for preparing Ti4O7

A titanium powder and microwave sintering technology, which is applied in the field of titanium materials, can solve the problems of high preparation conditions and low product quality, and achieve good application prospects, lower reaction temperature, and ease of sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

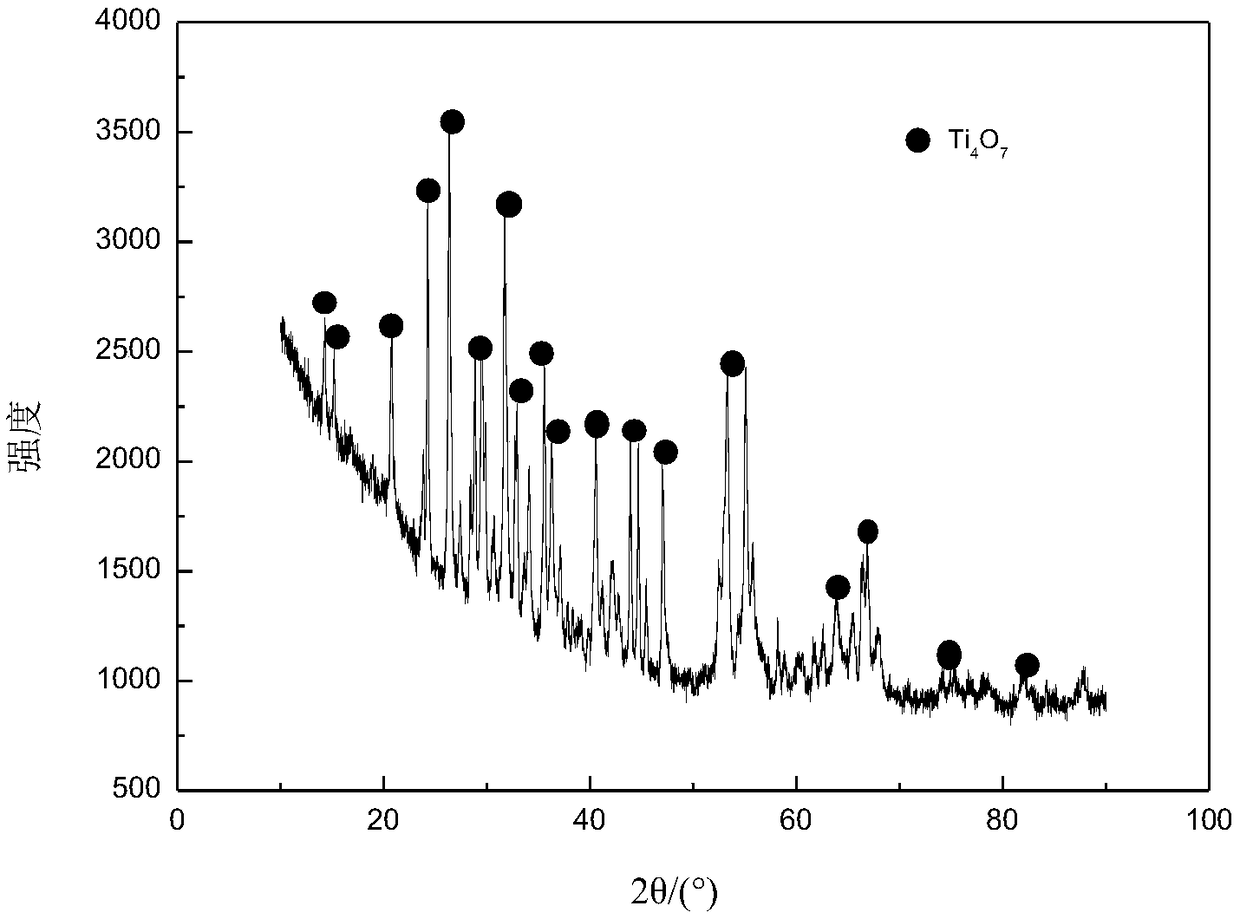

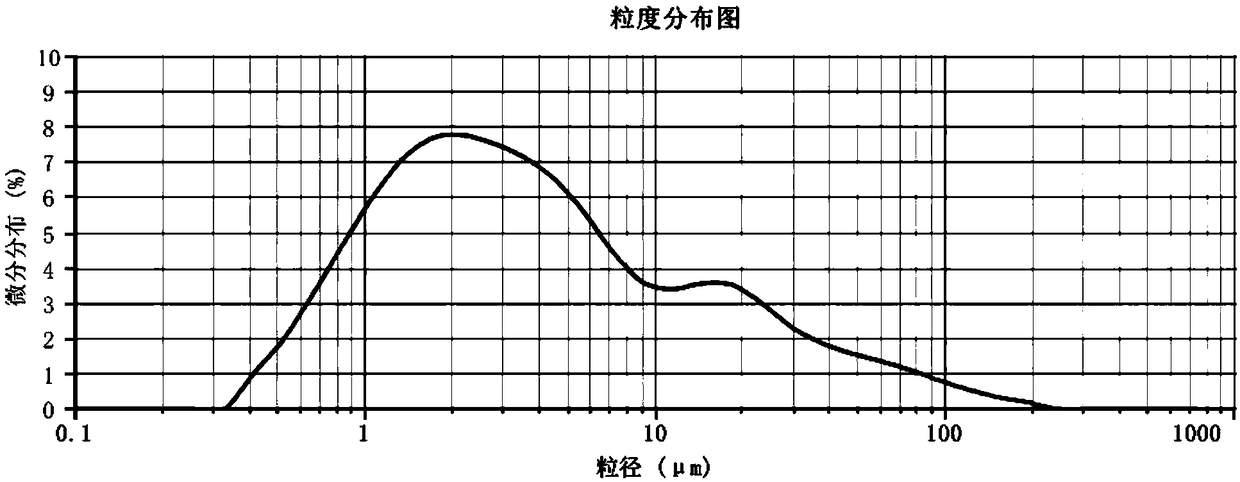

[0030] Embodiment 1 uses the method of the present invention to prepare micron Ti 4 o 7

[0031] With titanium powder (2 As raw material, a total of 608g (including titanium powder 48g, TiO 2 560g), put the prepared raw materials into a ball mill for ball milling, and the ball milling time is 2h. After the ball milling, take out the raw materials, put them in a corundum crucible, and then put the loaded corundum crucible into a microwave oven for heating and sintering. The sintering temperature 1150°C, sintering time 1h, while using argon as a protective gas. After the sintering is completed, the microwave oven is naturally cooled to room temperature, the microwave oven is turned on, the product is taken out, and the product is ground, broken, and detected and analyzed to confirm that the final product is Ti 4 o 7 , purity > 99%.

Embodiment 2

[0032] Embodiment 2 uses the method of the present invention to prepare micron Ti 4 o 7

[0033] With titanium powder (2 As raw material, a total of 304g (including titanium powder 24g, TiO 2 280g), put the prepared raw materials into a ball mill for ball milling, the ball milling time is 1h, after the ball milling is over, take out the raw materials, put them into a corundum crucible, then put the corundum crucible with the materials into a microwave oven and carry out under vacuum conditions. Heating and sintering, the sintering temperature is 750°C, and the sintering time is 4h. After the sintering is completed, the microwave oven is naturally cooled to room temperature, the microwave oven is turned on, the product is taken out, and the product is ground, broken, and detected and analyzed to confirm that the final product is Ti 4 o 7 , purity > 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com