A chemical mechanical polishing pad and method for planarizing substrate thereof

A chemical mechanical and polishing pad technology, applied in the direction of grinding tools, etc., can solve problems such as inhomogeneity, uneven gel in the reaction system, and affect polishing performance, so as to reduce excessive heat release, suppress heat release, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

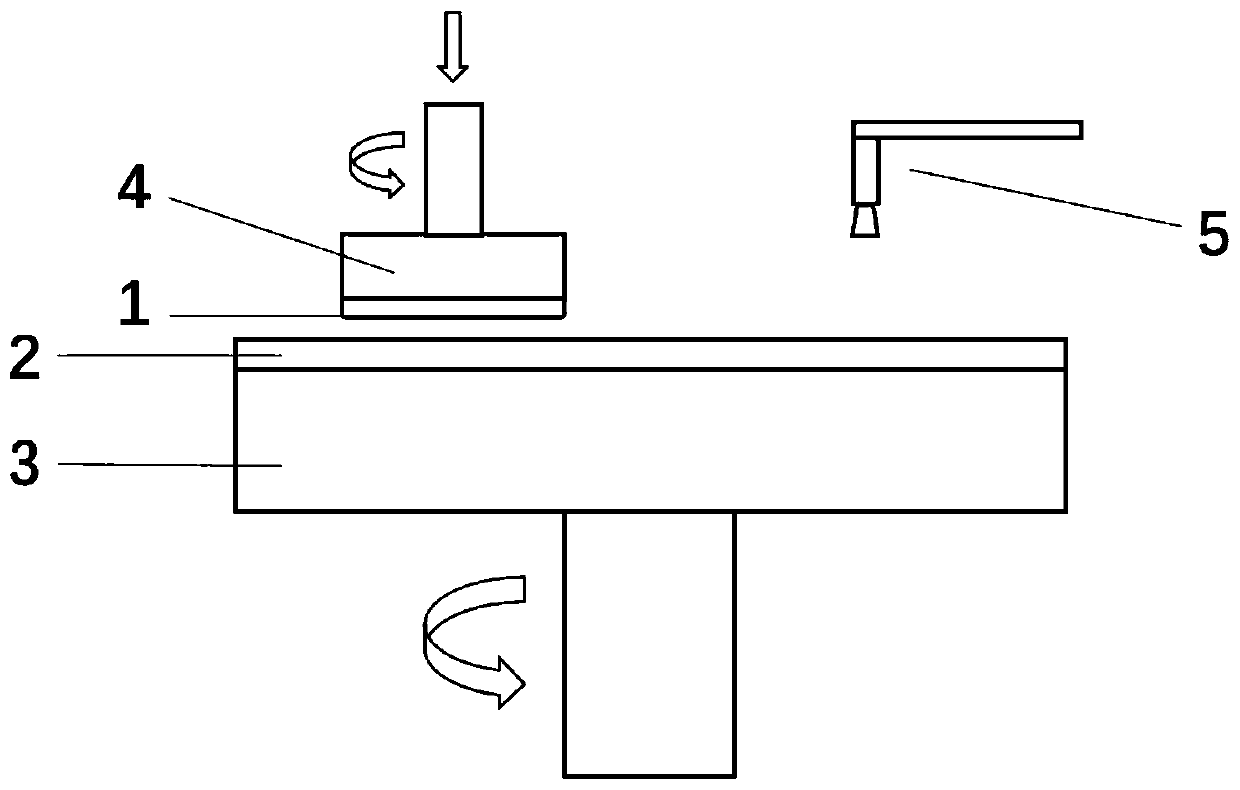

[0118] Preparation method of polishing layer

[0119] The present invention also provides a preparation method of the above-mentioned polishing layer. The preparation method of the polishing layer of the present invention can be the pouring curing process conventionally used in the art, and the preparation method comprises the following steps:

[0120] (1) Optionally, pour the casting composition capable of producing an endpoint detection zone corresponding to the hardness into the inner cavity of the mold, solidify, demould, and polish the surface to obtain a cylindrical block;

[0121] (2) Place the cylindrical block obtained in the optional step (1) in the annular side wall of the polishing layer mold, and pour the above-mentioned polishing layer raw material capable of producing a polishing zone with corresponding hardness into the annular inner cavity Combining, curing, demoulding, and surface grinding to obtain a cylindrical solidified block;

[0122] (3) Slicing the...

Embodiment 1

[0132] Present embodiment provides a kind of polyurethane polishing layer, and its preparation method is as follows:

[0133] Step 1. Treatment of the isocyanate-terminated polyurethane prepolymer (or prepolymer for short).

[0134] 100 parts by mass of the isocyanate-terminated prepolymer obtained by the reaction of toluene diisocyanate and polytetrahydrofuran (containing 8.75 to 9.05% by mass of unreacted NCO groups) was heated to 80°C and degassed under vacuum (~0.095MPa) for 2 hour, so that the gas and the small molecular compound in the prepolymer are removed; Then add 0.86 parts by mass of the hollow microsphere polymer with an average diameter of 40 microns, and make the hollow microsphere polymer evenly disperse in the prepolymer under stirring , degas again under vacuum (~0.095MPa) for 2 hours, then lower the temperature to 50°C and set aside.

[0135] Step 2, preparation of curing agent composition.

[0136] Heat 23.5 parts by mass of MOCA to 115°C to make it compl...

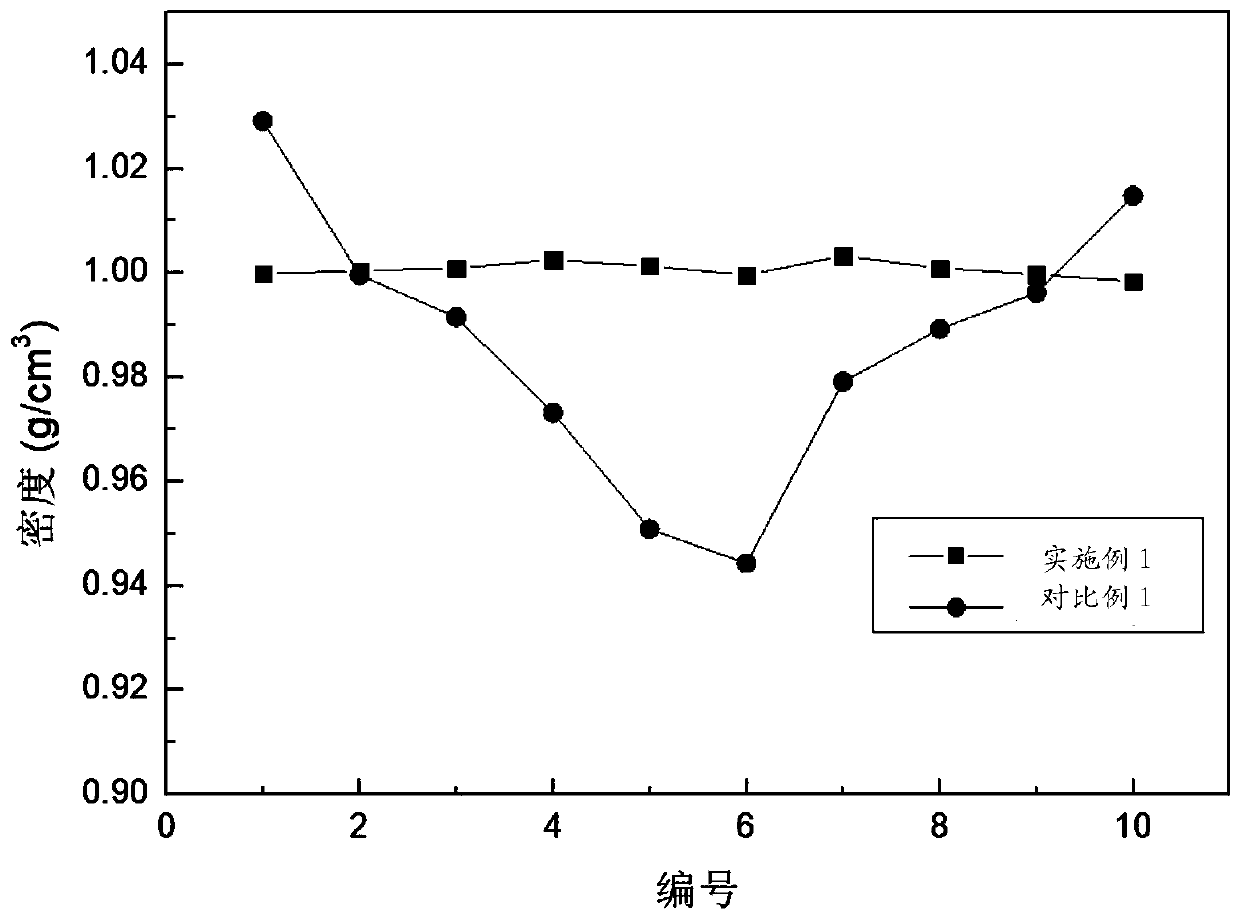

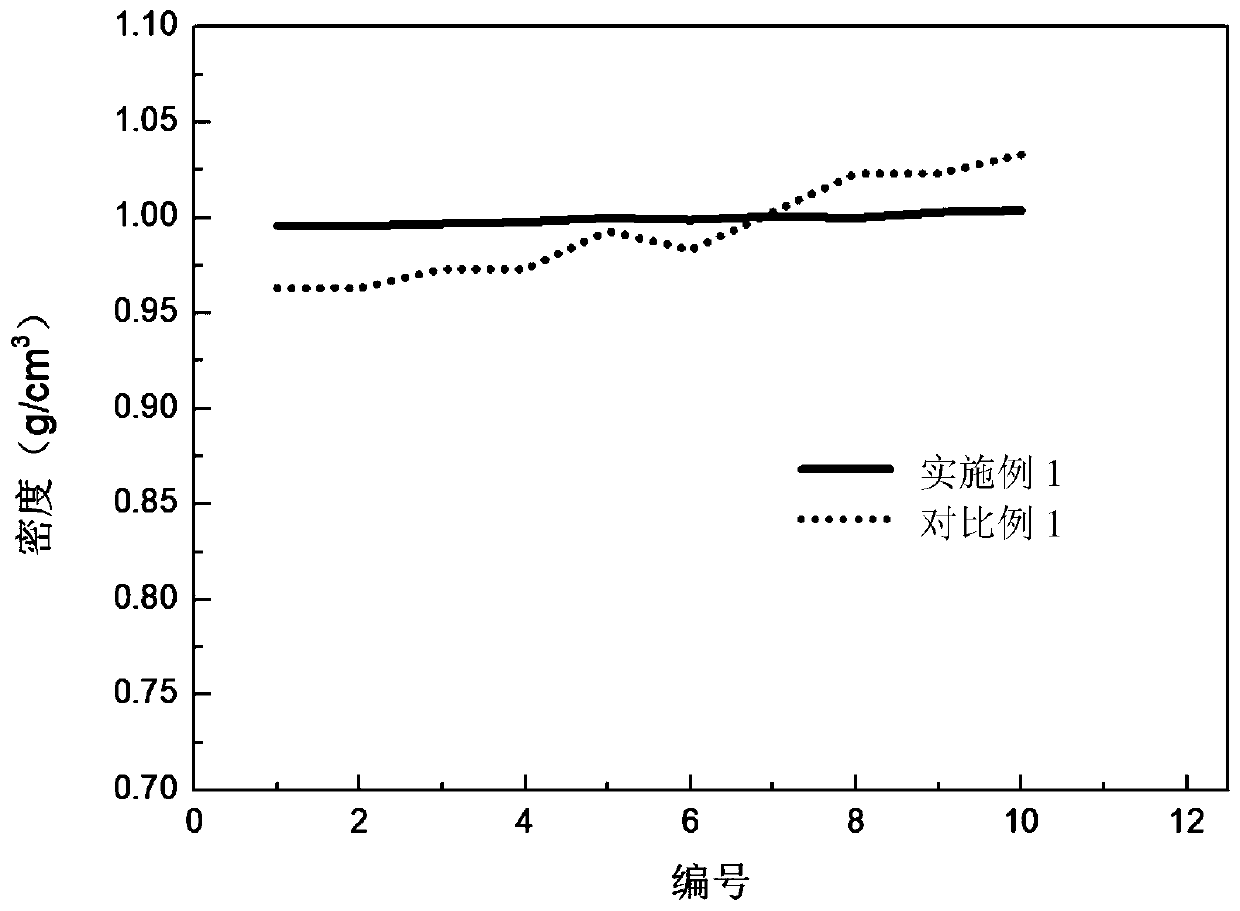

Embodiment 2~15

[0145] Using the same process as in Example 1, selecting different grades of aliphatic-terminated secondary amino polyethers, prepolymers with different unreacted NCO contents, hollow microsphere polymers with different average diameters, and different chain extension coefficients, you can obtain different Effect polyurethane finish. Each raw material and its dosage are summarized in Table 1 and Table 2, wherein the amounts of all materials are parts by mass. The hardness, density and compressibility of the polyurethane polishing layer prepared in each embodiment were measured according to the method in Example 1, and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com