Organic-inorganic composite film and preparation method thereof

An inorganic composite membrane and inorganic composite technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of composite membrane flux attenuation, large pollutant treatment capacity, etc., and achieve high hydrophilicity and high flux , Conducive to the effect of large-scale continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Select a copolymer of acrylonitrile and acrylic acid with a molar content of acrylic acid of 90% and a number average molecular weight of 5000 g / mol as a polymer, dissolve the polymer and polyvinylidene fluoride in N,N-dimethylformamide, stir and mix Uniform, standing for defoaming, the obtained polymer mass fraction is 15% (that is, the mass ratio of polymer to film-forming solution is 15:100).

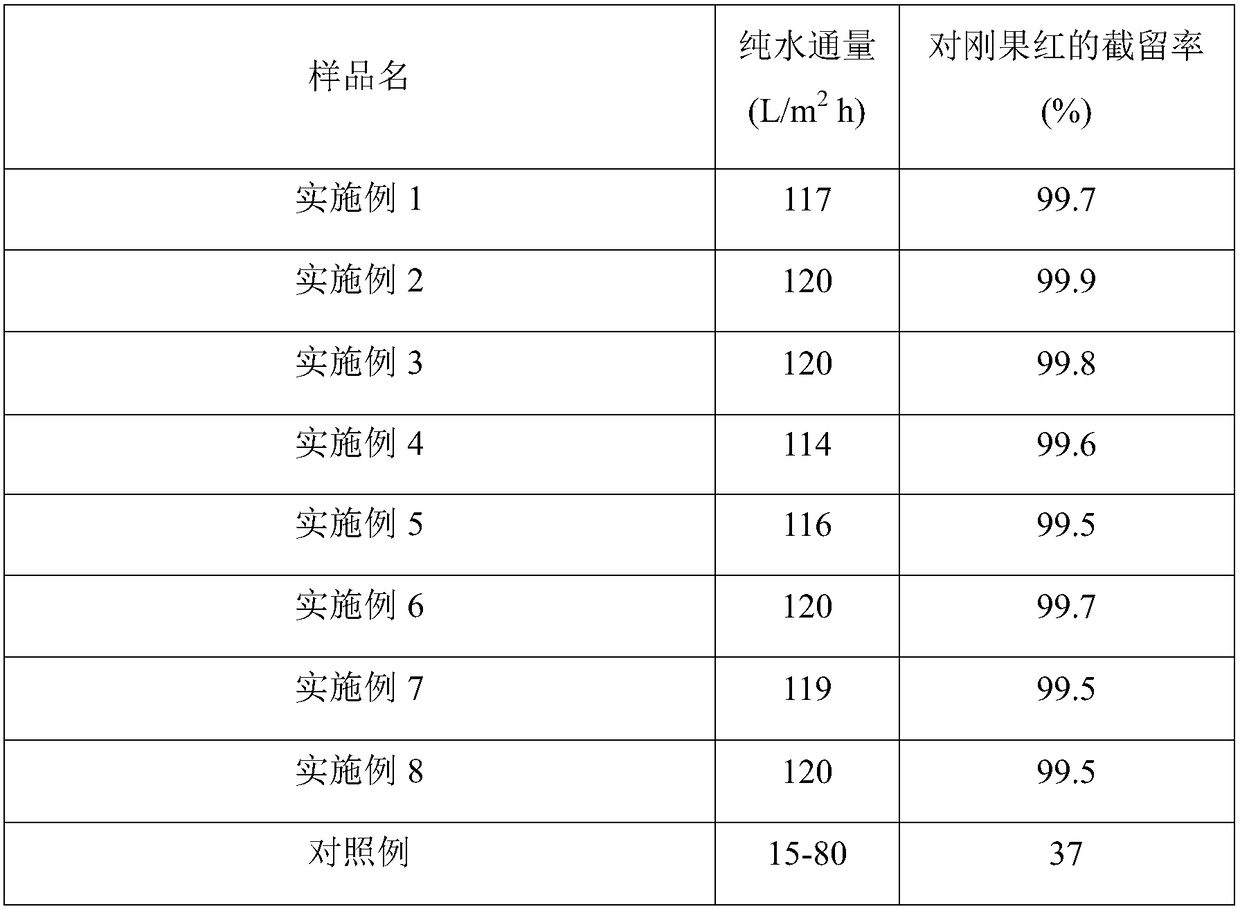

[0033] The membrane-forming solution is transferred into a membrane-forming coagulation bath to prepare an organic ultrafiltration membrane. The organic ultrafiltration membranes were impregnated in 0.1M CaCl 2 Aqueous solution, deionized water, 0.1M Na 2 CO 3 The aqueous solution and deionized water were used for 10 seconds, and one cycle was regarded as one deposition. After five cycles of deposition, the composite film was placed in a clear water bath for oscillating cleaning for 20 hours to obtain the organic-inorganic composite film. The pure water flux of the composit...

Embodiment 2

[0035]Select a copolymer of methyl methacrylate and acrylic acid with a molar content of 10% acrylic acid and a number average molecular weight of 60,000 g / mol as the polymer, and dissolve the polymer and polyvinylidene fluoride in N,N-dimethylacetamide , dissolve the polymer and polyvinylidene fluoride in N,N-dimethylformamide, stir and mix evenly, let stand for defoaming, and obtain a polymer mass fraction of 10% (that is, the mass of the polymer and the film-making solution The ratio is 10:100).

[0036] The membrane-forming solution is transferred into a membrane-forming coagulation bath to prepare an organic ultrafiltration membrane. The organic ultrafiltration membranes were impregnated in 0.2M CaCl 2 Aqueous solution, deionized water, 0.2M Na 2 CO 3 The aqueous solution and deionized water were used for 10 seconds, and one cycle was regarded as one deposition. After 10 cycles of deposition, the composite film was placed in a clear water bath and washed for 20 hours b...

Embodiment 3

[0038] Select the copolymer of styrene and hydroxyethyl methacrylate with a molar content of 30% of hydroxyethyl methacrylate and a number average molecular weight of 10000g / mol as a polymer, and dissolve the polymer and polyacrylonitrile in N,N- In dimethylacetamide, stir and mix evenly, let stand for defoaming, and obtain a polymer mass fraction of 12% (ie, the mass ratio of the polymer to the film-forming solution is 12:100).

[0039] The membrane-forming solution is transferred into a membrane-forming coagulation bath to prepare an organic ultrafiltration membrane. The organic ultrafiltration membrane was immersed in 0.2M tetraethyl orthosilicate aqueous solution, deionized water, 0.2M hydrochloric acid aqueous solution, and deionized water for 10 seconds, and one cycle was one deposition. After deposition for 8 cycles, the composite The membrane was shaken and washed in a water bath for 20 hours to obtain the organic-inorganic composite membrane. The pure water flux of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com