A preparation method and application of a back electrode of a solar cell

A solar cell and back electrode technology, which is applied in the field of solar cells, can solve the problems of affecting the welding performance of the back electrode, increasing the cost of the back electrode paste, and increasing the width of the back electrode, so as to improve the photoelectric conversion efficiency, avoid serious leakage problems, and improve The effect of solderability and solder resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0030] A method for preparing the back electrode of a solar cell, printing or spraying a layer of conductive barrier layer slurry on the back aluminum paste, the barrier layer slurry is directly printed on the back aluminum electrode, and after drying, a matching back electrode is printed on it The silver paste is dried and sintered to form the back electrode.

[0031] The barrier layer slurry includes the following in parts by weight: a total of 67 parts of metal nitride powder, silicon nitride compound powder, metal oxide powder or low melting point metal powder, 3 parts of lead-free glass powder, organic adhesive 29.8 parts of binder, 0.2 parts of organic additives.

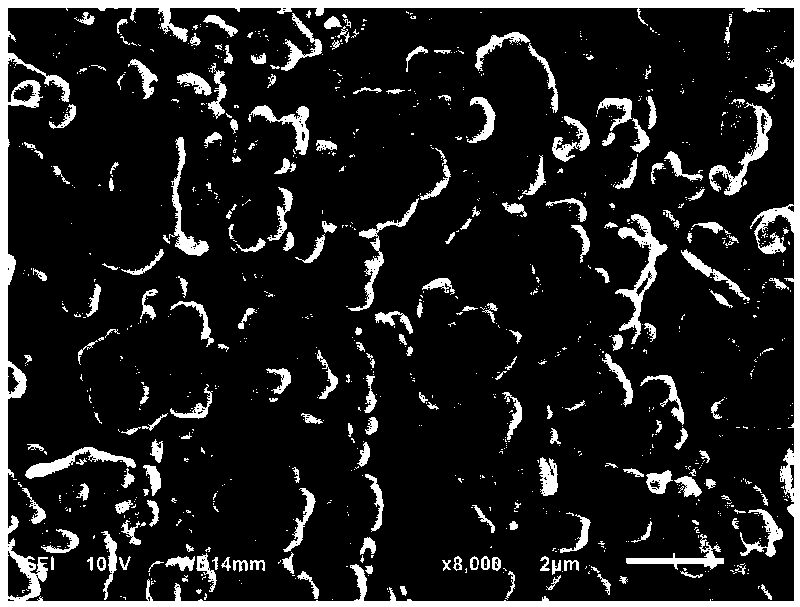

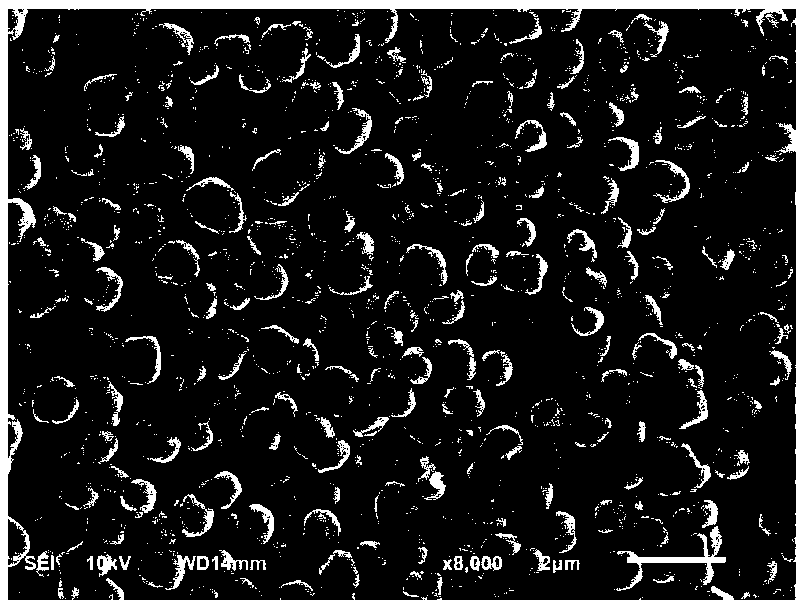

[0032] The back silver paste used in combination includes the following parts by weight: 42 parts of hollow spherical silver powder with a purity greater than 99.99%, 15 parts of flake silver powder, 2.5 parts of lead-free glass powder, 40.1 parts of organic binder, 0.4 parts of organic auxiliary agent; where...

specific Embodiment 2

[0048] A method for preparing the back electrode of a solar cell, printing or spraying a layer of conductive barrier layer slurry on the back aluminum paste, the barrier layer slurry is directly printed on the back aluminum electrode, and after drying, a matching back electrode is printed on it The silver paste is dried and sintered to form the back electrode.

[0049] The barrier layer slurry includes the following in parts by weight: a total of 60 parts of metal nitride powder, silicon nitride compound powder, oxide powder or low-melting point metal powder, 5 parts of lead-free glass powder, organic bonding 34 parts of additives, 1 part of organic additives.

[0050] The back silver paste used in combination includes the following in parts by weight: 40 parts of hollow spherical silver powder with a purity greater than 99.99%, 20 parts of flake silver powder, 4 parts of lead-free glass powder, 35 parts of organic binder, 1 part of organic auxiliary agent; wherein, the parti...

specific Embodiment 3

[0066] A method for preparing the back electrode of a solar cell, printing or spraying a layer of conductive barrier layer slurry on the back aluminum paste, the barrier layer slurry is directly printed on the back aluminum electrode, and after drying, a matching back electrode is printed on it The silver paste is dried and sintered to form the back electrode.

[0067] The barrier layer slurry includes the following in parts by weight: a total of 58 parts of metal nitride powder, silicon nitride compound powder, metal oxide powder or low melting point metal powder, 3.5 parts of lead-free glass powder, organic adhesive 37.8 parts of binder, 0.7 parts of organic additives.

[0068] The back silver paste used in combination includes the following parts by weight: 45 parts of hollow spherical silver powder with a purity greater than 99.99%, 18 parts of flake silver powder, 3 parts of lead-free glass powder, 33.4 parts of organic binder, 0.6 parts of organic auxiliary agent; where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com