Medium-thick epitaxial preparation method

A thick epitaxy and epitaxy technology used in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

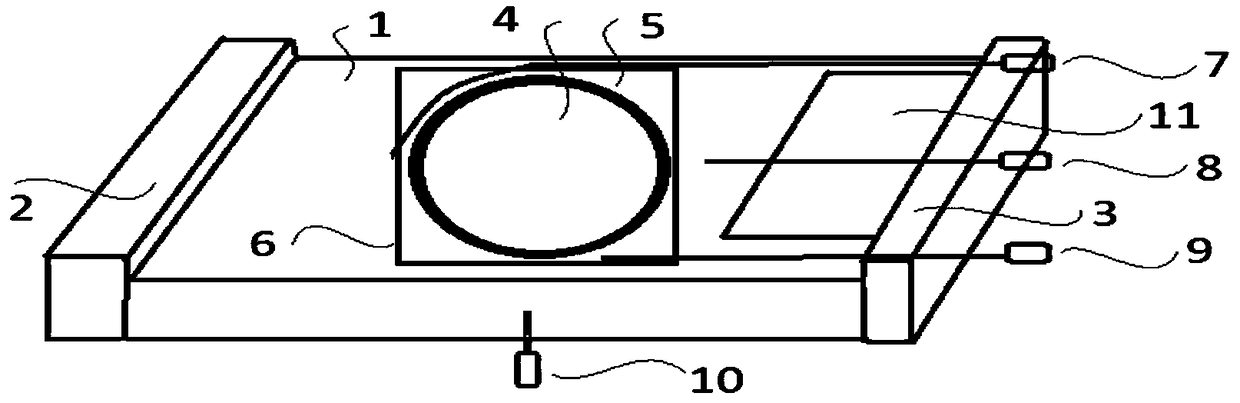

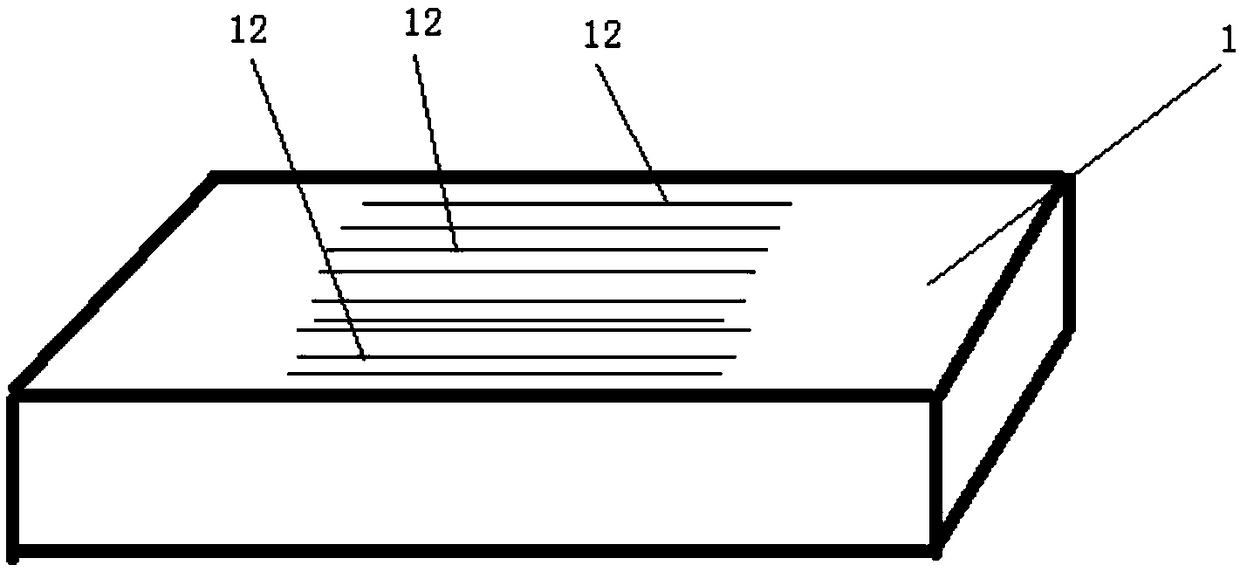

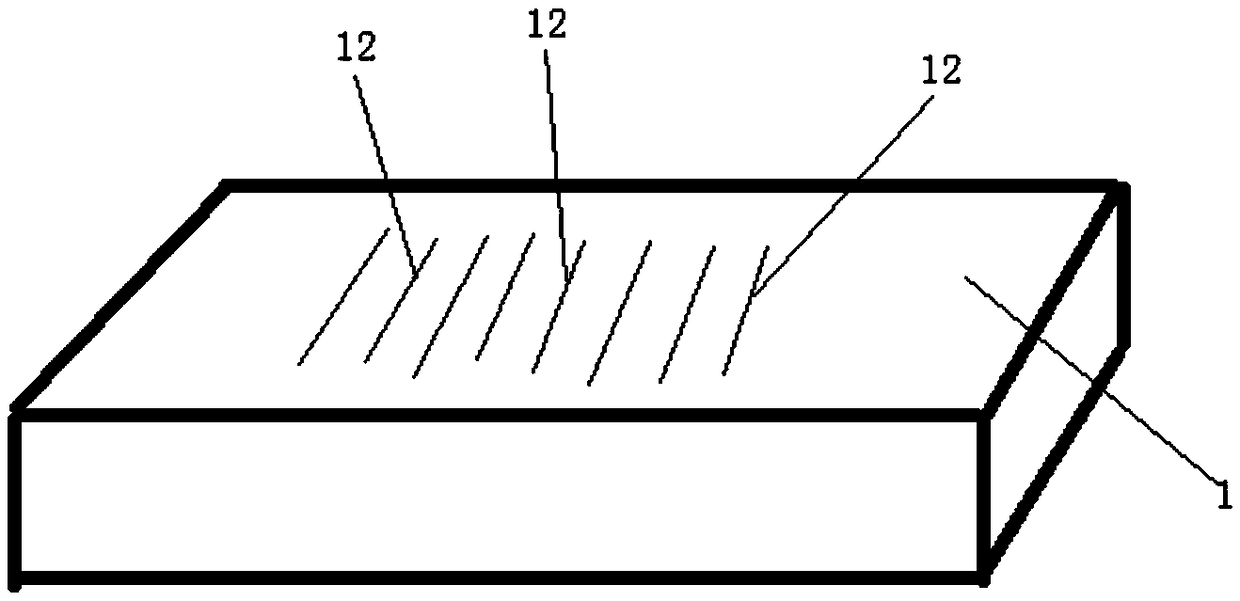

[0025] The preparation method of thick epitaxy in this embodiment includes the following steps: Step one, etching the cavity 1, wherein a heat absorption device is provided between the base of the cavity 1 and the air outlet,

[0026] Step a: First, perform a 15-second temperature increase to increase the temperature of the cavity 1 to 1120°C. During this process, 3 liters of hydrogen gas per minute is passed;

[0027] Step b. Then perform the first step of etching. The duration is 10 seconds, the temperature is maintained at 1120°C, the hydrogen is 3 liters / minute, and the hydrogen chloride is 15 liters / minute;

[0028] Step c. Then perform the second step of etching. The duration is 8*(T-4) seconds, and the duration is at least 15 seconds. T is the epitaxial thickness that needs to be grown on the silicon wafer in the cavity 1, such as a certain type of customer The product epitaxial thickness specification is 6 microns or 30 microns, T is correspondingly set to 6 or 30, the temper...

Embodiment 2

[0036] The preparation method of thick epitaxy in this embodiment includes the following steps: step one, etching the cavity 1, wherein a heat absorption device is provided between the base of the cavity 1 and the air outlet,

[0037] Step a: First, perform a temperature increase for 20 seconds to increase the temperature of the cavity 1 to 1170°C. During this process, 5 liters of hydrogen gas per minute is passed;

[0038] Step b. Then perform the first step of etching, which lasts for 15 seconds, maintains the temperature at 1170°C, blows 5 liters / min of hydrogen, and blows 20 liters / min of hydrogen chloride;

[0039] Step c. Then perform the second step of etching. The duration is 8*(T-2) seconds, and the duration is at least 20 seconds. T is the epitaxial thickness that needs to be grown on the silicon wafer in the cavity 1, and the temperature is maintained at 1170°C. 20 liters of hydrogen per minute and 20 liters of hydrogen chloride per minute;

[0040] The heat absorption devi...

Embodiment 3

[0052] The preparation method of thick epitaxy in this embodiment includes the following steps: step one, etching the cavity 1, wherein a heat absorption device is provided between the base of the cavity 1 and the air outlet,

[0053] Step a. First, perform a temperature increase of 17 seconds to increase the temperature of the cavity 1 to 1150°C. During this process, 4 liters of hydrogen gas per minute is passed;

[0054] Step b. Then perform the first step of etching, the duration is 12 seconds, the temperature is maintained at 1150°C, the hydrogen gas is 4 liters / min, and the hydrogen chloride is 17 liters / min;

[0055] Step c. Then perform the second step of etching. The duration is 8*T seconds and the duration is at least 18 seconds. T is the epitaxial thickness that needs to be grown on the silicon wafer in the cavity 1, the temperature is maintained at 1150°C, and the hydrogen gas is 18 liters / Minutes, and 18 liters of hydrogen chloride per minute;

[0056] The heat absorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com