Jeans silk-screen printing ink and preparation method thereof

A technology of screen printing and ink, applied in the direction of ink, household appliances, application, etc., can solve the problems of low wear resistance, unwearable clothing, poor ink adhesion, etc., to achieve high wear resistance and increase the effect of wearing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of above-mentioned jeans screen printing ink comprises the following steps:

[0027] (1) At room temperature, put the glue into the mixing container;

[0028] ⑵Put in natural environmental protection resin and epoxy resin and stir evenly;

[0029] ⑶ Add appropriate amount of color essence;

[0030] ⑷Add thickener, hard film agent MA, hard film agent MB and hot melt in turn, and stir evenly to obtain the finished product.

Embodiment

[0032] Denim jacket with yellow text printed on the back, choose yellow color essence, and fix the fabric on the workbench through clamps.

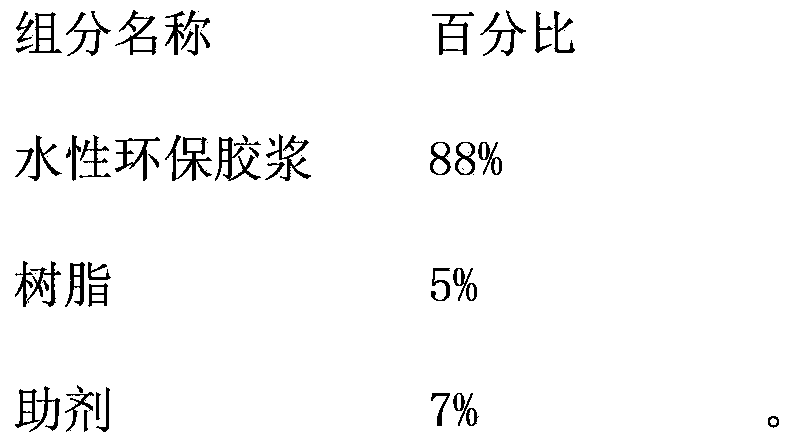

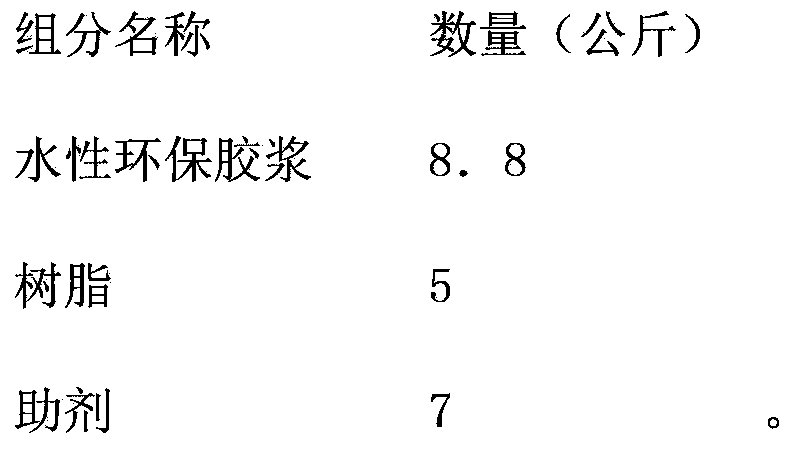

[0033] Inks were prepared according to the following recipe:

[0034]

[0035] Among them, the weight ratio of natural environmental protection resin and epoxy resin in the resin is 3:2, and the weight ratio of thickener HC-902, hard film agent MA, hard film agent MB and hot melt agent EVA360 is 2:2:2:1 .

[0036] Add the prepared ink to the template, and apply a layer evenly; then place the template on the top of the fabric, and use the scraper to scrape off the excess ink evenly; after the 20 patterns on the workbench are printed, start the workbench The heating car, which runs at a constant speed under the drive of the motor, reciprocates heating once at a temperature of 110 degrees Celsius to complete the printing of the pattern.

[0037] In the present invention, the water-based environmental protection glue, natural environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com