Heat conduction enhanced inorganic PCM (phase change material) and preparation method thereof

An inorganic phase change material and a technology for enhancing thermal conductivity. It is used in heat exchange materials, chemical instruments and methods. It can solve the problems of low thermal conductivity and achieve the effects of high heat storage density, fast thermal response speed, and safe raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

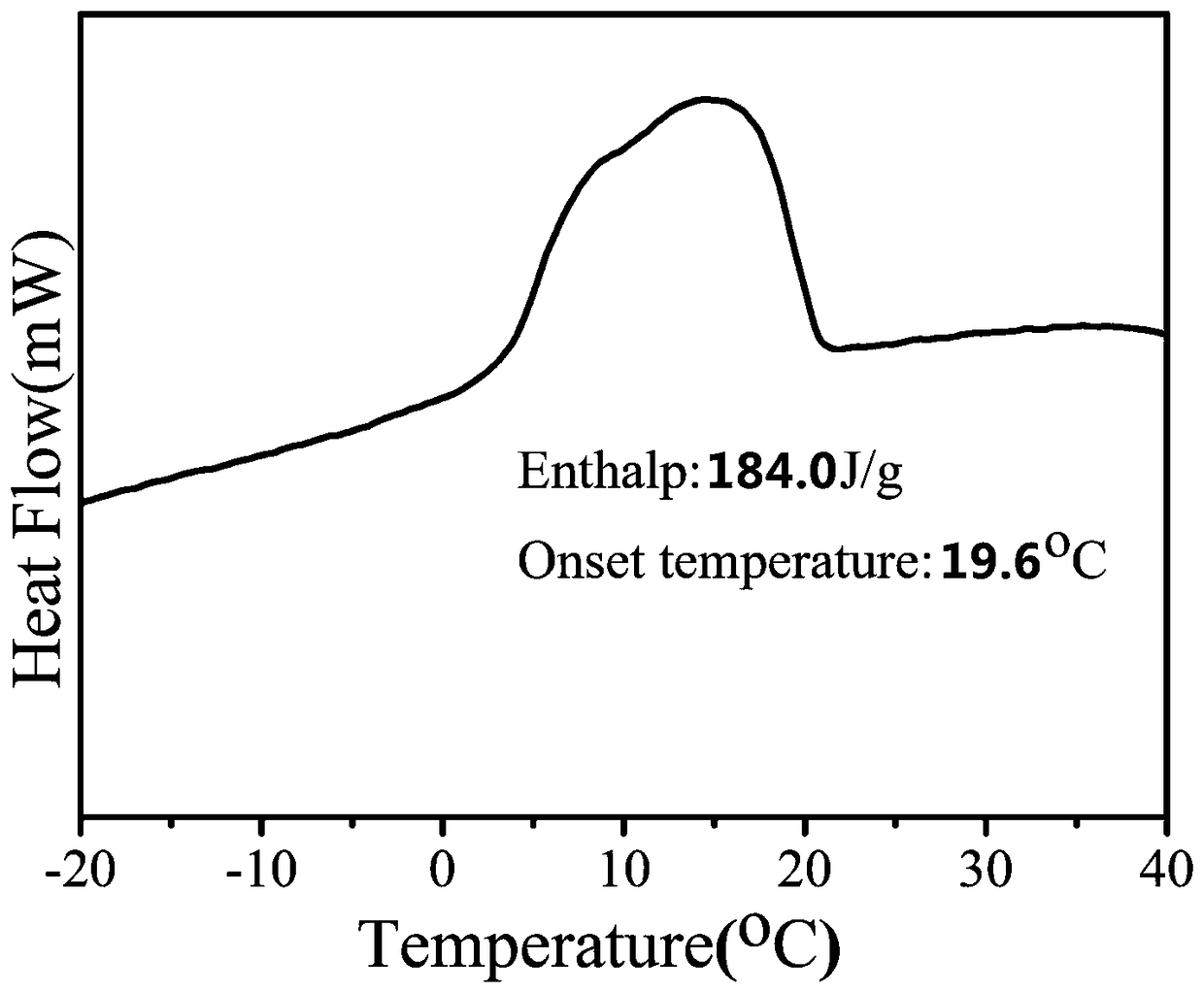

Embodiment 1

[0031] Preparation method of heat conduction enhanced inorganic phase change energy storage material:

[0032] Step 1, the modification treatment of nano thermal conductivity enhancing particles, adding boron nitride to 60% sodium hydroxide solution, filtering in water bath at 90°C for 2 hours, and drying at 90°C for 20 hours;

[0033] Step 2, the preparation of the wall material prepolymer by adding the modified nano heat conduction enhancing particles, mixing the nano heat conduction enhancing particles with the monomer melamine and formaldehyde of the melamine resin, and ultrasonically forming the prepolymer;

[0034] Step 3, melting the inorganic phase change material, mixing the inorganic phase change material with a nucleating agent with a mass fraction of 1% and heating until the inorganic phase change material is completely melted;

[0035] Step 4, preparation of heat conduction-enhanced inorganic phase-change energy storage materials, adding the melted inorganic phase...

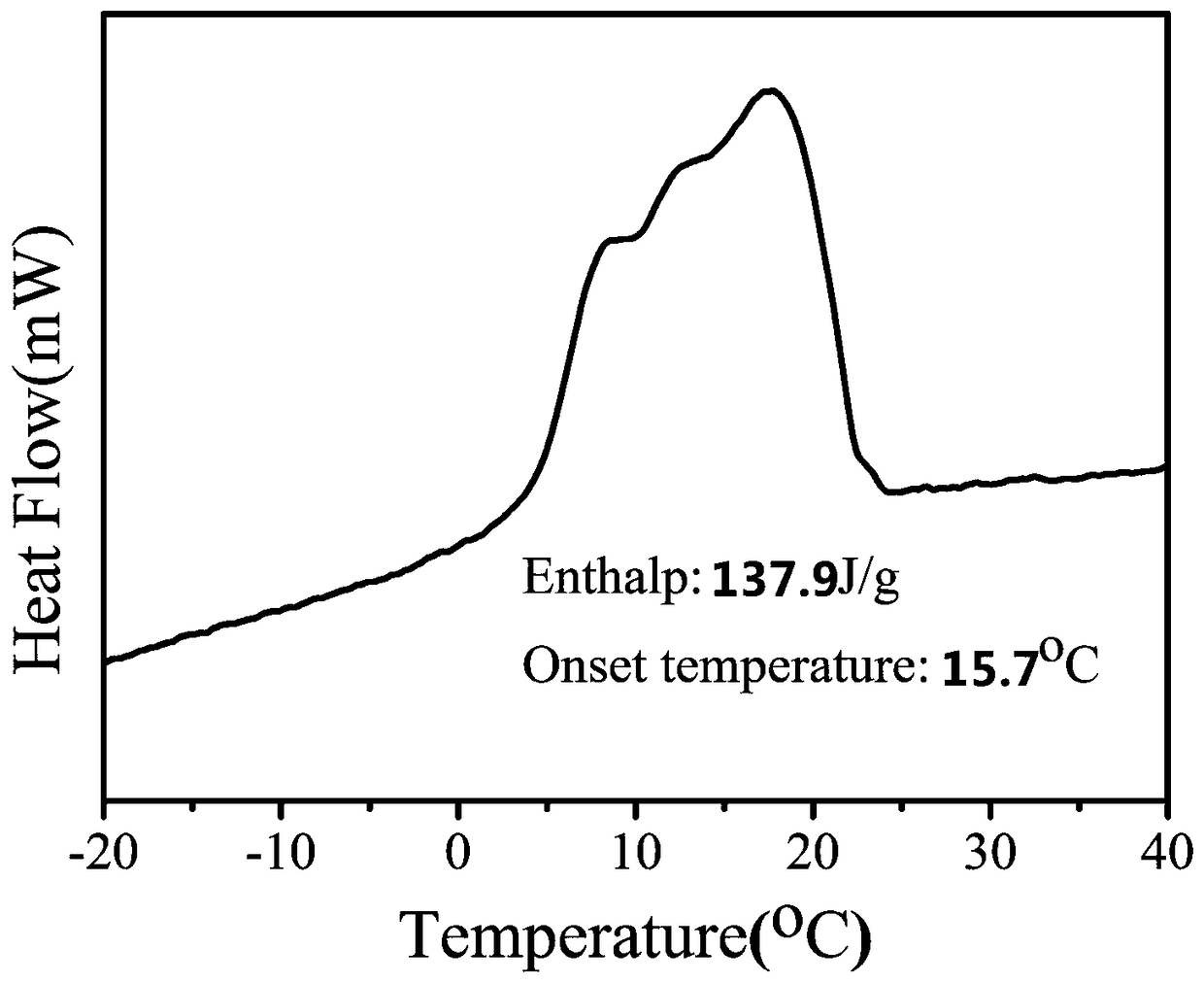

Embodiment 2

[0038] Preparation method of heat conduction enhanced inorganic phase change energy storage material:

[0039] The steps not specifically described are the same as in Example 1, the difference is that: Step 1, modification of nano thermal conductivity enhancing particles, 1.2 grams of carbon nanotubes are added to 50 mL of concentrated sulfuric acid, mixed with magnetic force for 30 minutes, ultrasonicated for 2 hours, and then added Mix 50mL of concentrated nitric acid with magnetic stirring for 30min, react at 130°C for 2h, cool, dilute, filter and dry.

[0040] The obtained thermal conductivity enhanced organic phase change energy storage material was determined by DSC experiment, and the results are as follows: figure 2 As shown, the latent heat of phase change is 137.9J / g.

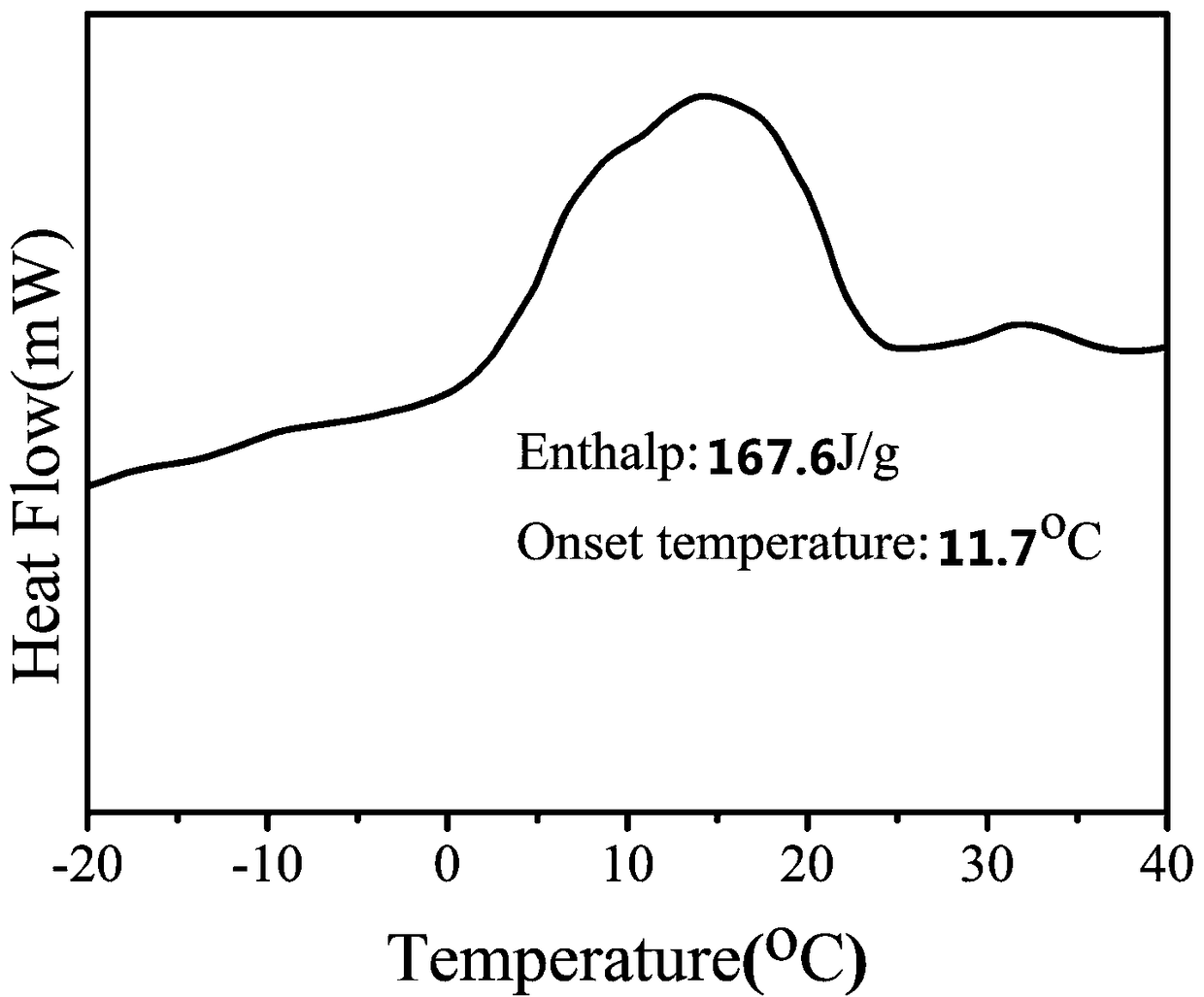

Embodiment 3

[0042] Preparation method of heat conduction enhanced inorganic phase change energy storage material:

[0043] The steps not specifically described are the same as in Example 1, except that: Step 1, the modification treatment of nano thermal conductivity enhancing particles, adding 3 grams of natural graphite to a mixture of 20 grams of potassium permanganate, 350 mL of concentrated sulfuric acid and 50 mL of concentrated phosphoric acid The solution was reacted at 80°C for 10 h, cooled to room temperature, and then added 5 mL of 30% hydrogen peroxide until the solution turned light yellow, washed with hydrochloric acid and distilled water for 3 times, and then dried at 90°C.

[0044] The obtained thermal conductivity enhanced organic phase change energy storage material was determined by DSC experiment, and the results are as follows: image 3 As shown, the latent heat of phase change is 167.6J / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com