UV-LED packaging adhesive and preparation method thereof

A UV-LED, encapsulating adhesive technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low refractive index, easy to produce yellowing, poor anti-vulcanization performance, etc., to achieve high refractive index rate, excellent UV resistance, good vulcanization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A UV-LED encapsulant, which is made by mixing component A and component B at a mass ratio of 1:1;

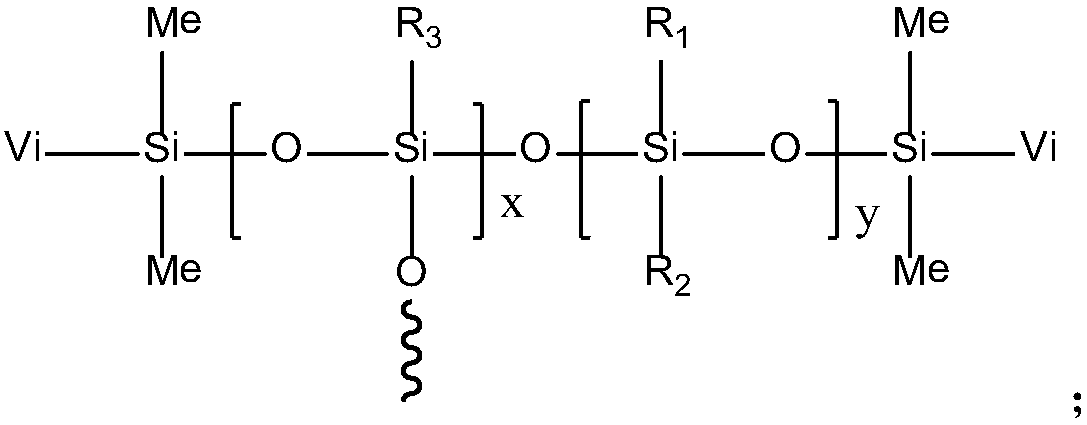

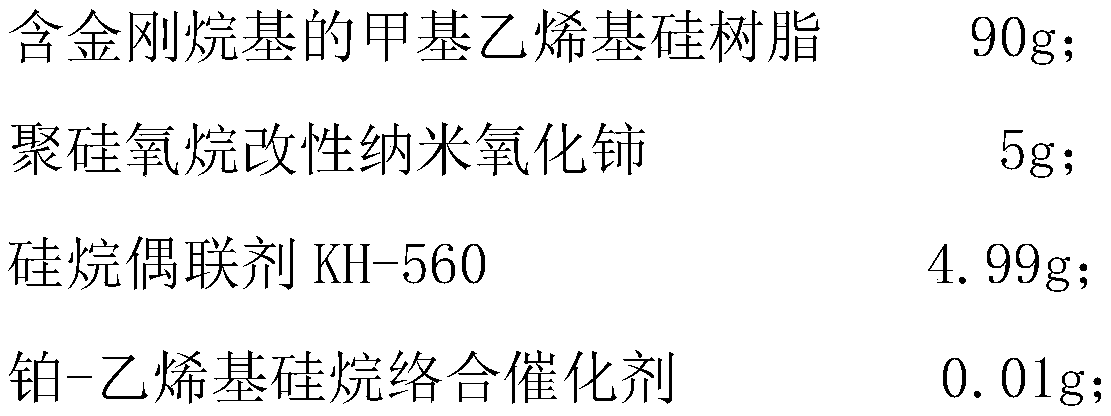

[0054] Component A includes the following ingredients:

[0055]

[0056] Component A includes the following ingredients:

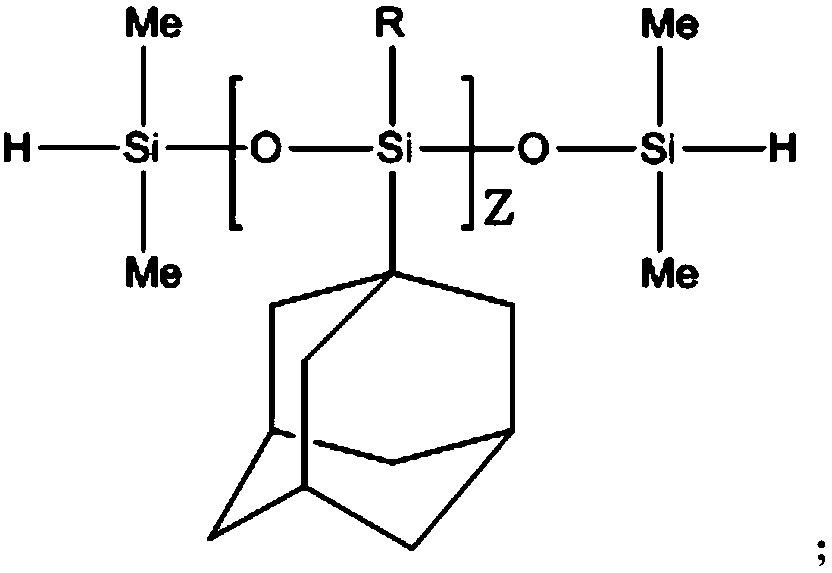

[0057] 30g of adamantyl-containing methyl vinyl silicone resin;

[0058] 69.99g of adamantyl-containing methyl hydrogen silicone oil;

[0059] Methylbutynol 0.01g;

[0060] The preparation method of UV-LED encapsulation adhesive in this embodiment comprises the following steps:

[0061] a) Weigh 90g of adamantyl-containing methyl vinyl silicone resin, 5g of polysiloxane-modified nano-cerium oxide (Dongguan Luyue AHR-3), 4.99g of silane coupling agent KH-560 and 0.01g of platinum -Vinylsilane complex catalyst (platinum content: 5000ppm), sequentially added to the vacuum mixer, mixed evenly to obtain A component;

[0062] b) Weigh 30g of adamantyl-containing methyl vinyl silicone resin, 69.99g of adamantyl-containing methyl hydrogen-containing s...

Embodiment 2

[0065] A UV-LED encapsulant, which is made by mixing component A and component B at a mass ratio of 1:1;

[0066] Component A includes the following ingredients:

[0067]

[0068] Component A includes the following ingredients:

[0069] 49.5g of adamantyl-containing methyl vinyl silicone resin;

[0070] 50g of adamantyl-containing methyl hydrogen silicone oil;

[0071] Phenylbutynol 0.5g;

[0072] The preparation method of UV-LED encapsulation adhesive in this embodiment comprises the following steps:

[0073] a) Weigh 97.5g of adamantyl-containing methyl vinyl silicone resin, 1g of polysiloxane-modified nano-cerium oxide (Dongguan Luyue AHR-3), 1g of silane coupling agent KH-561 and 0.5g of platinum -Vinylsilane complex catalyst (platinum content: 5000ppm), sequentially added to the vacuum mixer, mixed evenly to obtain A component;

[0074] b) Weigh 49.5g of adamantyl-containing methyl vinyl silicone resin, 50g of adamantyl-containing methyl hydrogen-containing silicone...

Embodiment 3

[0077] A UV-LED encapsulant, which is made by mixing component A and component B at a mass ratio of 1:1;

[0078] Component A includes the following ingredients:

[0079]

[0080] Component A includes the following ingredients:

[0081] 50g of adamantyl-containing methyl vinyl silicone resin;

[0082] 49.5g of adamantyl-containing methyl hydrogen silicone oil;

[0083] Ethynylcyclohexanol 0.5g;

[0084] The preparation method of UV-LED encapsulation adhesive in this embodiment comprises the following steps:

[0085] a) Weigh 90g of adamantyl-containing methyl vinyl silicone resin, 4.5g of polysiloxane-modified nano-cerium oxide (Dongguan Luyue AHR-3), 5g of silane coupling agent KH-561 and 0.5g of platinum -Vinylsilane complex catalyst (platinum content: 5000ppm), sequentially added to the vacuum mixer, mixed evenly to obtain A component;

[0086] b) Weigh 50g of adamantyl-containing methyl vinyl silicone resin, 49.5g of adamantyl-containing methyl hydrogen-containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com