Water-based three-arm star-shaped multi-block ultraviolet-curing resin and preparation method thereof

A technology of curing resin and ultraviolet light, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as adverse production effects, affecting coating effects, and difficulty in perfect mutual solubility, and achieves short curing time and reduced coating process difficulty , the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

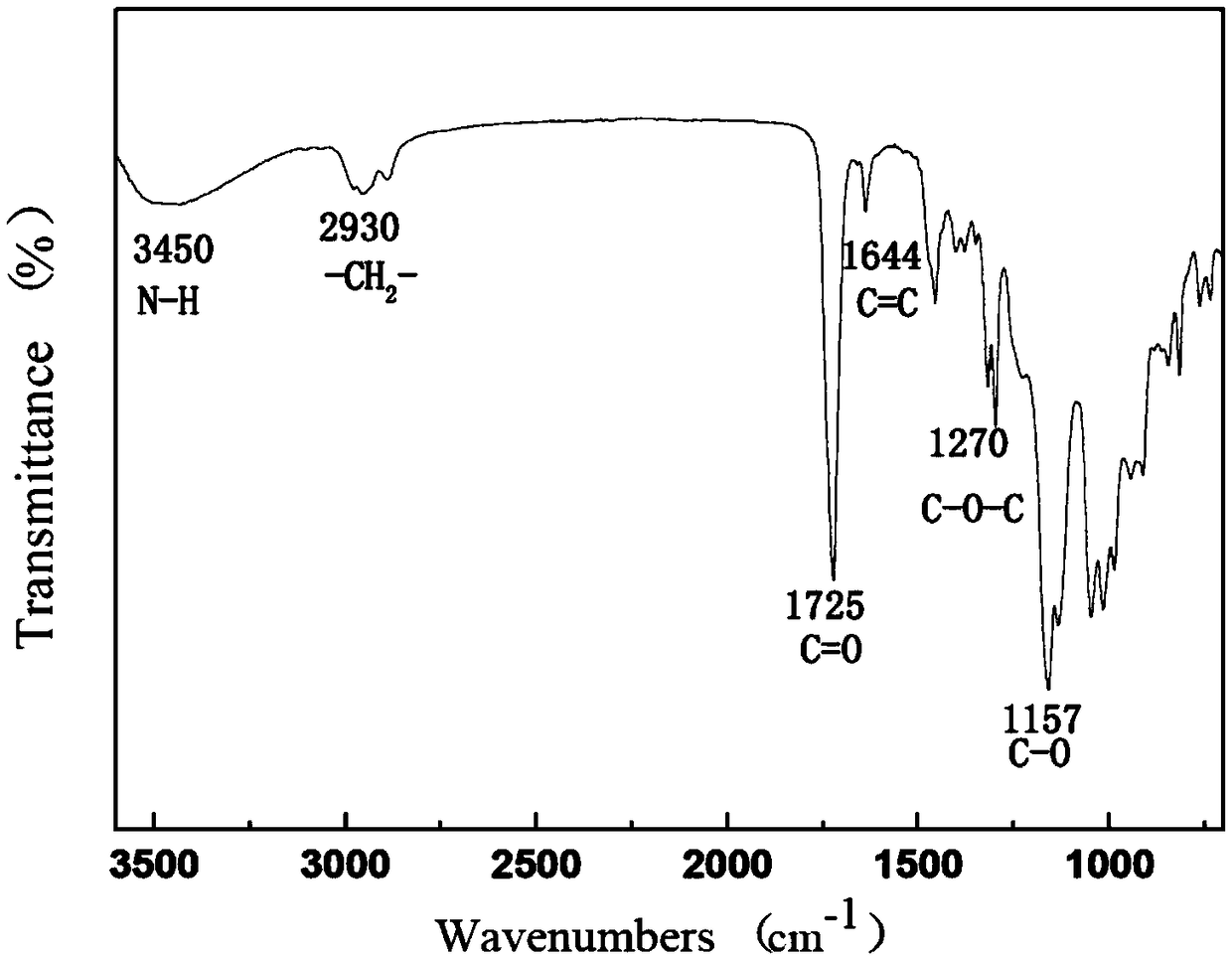

Embodiment 1

[0053] Weigh 13.42g (0.1mol) of trimethylolpropane and place it in a reaction kettle, add 0.01 (changed to 0.0013)g catalyst dibutyltin dilaurate, heat to 60°C, and blow nitrogen. Weigh 66.69 g (0.3 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and the reaction is kept for 3 hours. Weigh 40.24 g (0.3 mol) of 2,2-dimethylolpropionic acid, slowly add it into the reaction kettle, the feeding time is 3 hours, and the reaction is kept for 3 hours. Weigh 66.69 g (0.3 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and the reaction is kept for 3 hours. Weigh 600 g (0.3 mol) of polyethylene glycol with a molecular weight of 2000 g / mol, slowly add it into the reaction kettle, the feeding time is 3 hours, and the reaction is kept for 4 hours. Weigh 66.69 g (0.3 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and the...

Embodiment 2

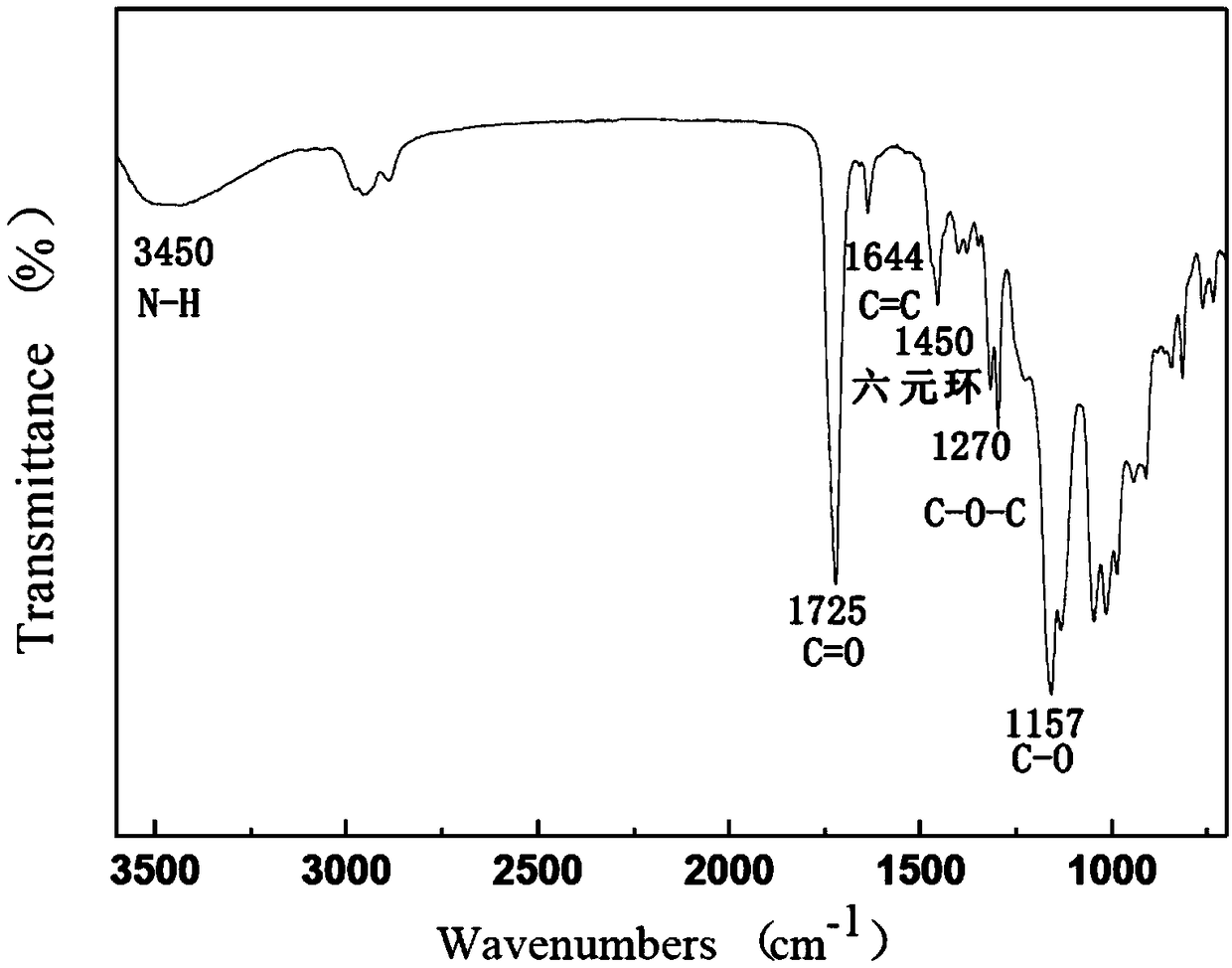

[0058] Weigh 13.42g (0.1mol) of trimethylolpropane and place it in a reaction kettle, add 0.01 (changed to 0.067)g catalyst tetraisopropyl titanate, heat to 60°C, and blow nitrogen. Weigh 66.69 g (0.3 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and the reaction is kept for 3 hours. Weigh 40.24 g (0.3 mol) of 2,2-dimethylolpropionic acid, slowly add it into the reaction kettle, the feeding time is 3 hours, and the reaction is kept for 3 hours. Weigh 66.69 g (0.3 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and the reaction is kept for 3 hours. Weigh 300 g (0.3 mol) of polyethylene glycol with a molecular weight of 1000 g / mol, slowly add it into the reaction kettle, the feeding time is 3 hours, and the reaction is kept for 4 hours. Weigh 66.69 g (0.3 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and t...

Embodiment 3

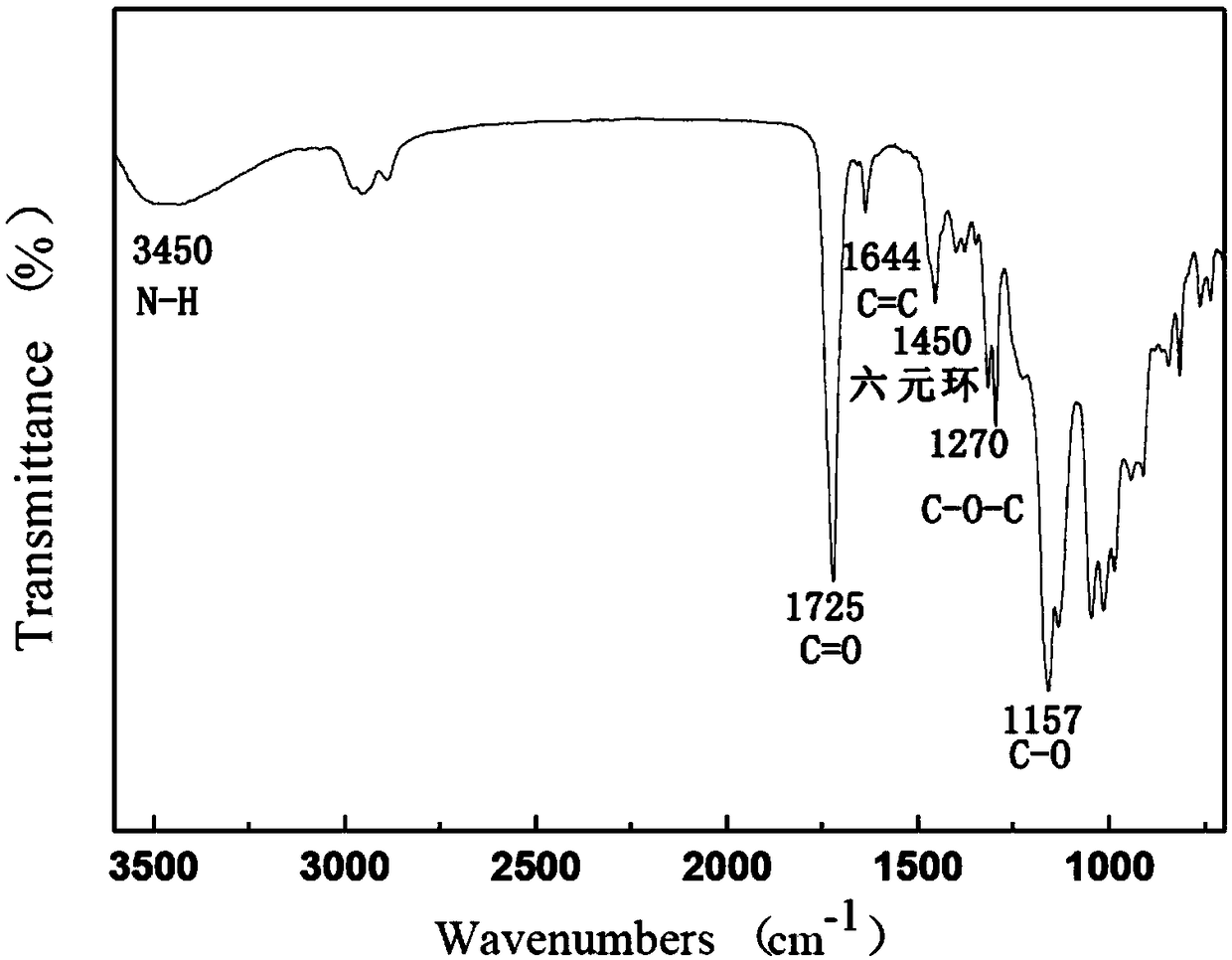

[0063] Weigh 13.42g (0.1mol) of trimethylolpropane and place it in a reaction kettle, add 0.01g of catalyst dibutyltin dilaurate, heat to 60°C, and blow nitrogen. Weigh 66.69 g (0.3 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and the reaction is kept for 3 hours. Weigh 41.14g (0.3mol) of diaminobenzoic acid, slowly add it into the reaction kettle, the feeding time is 3 hours, and keep warm for 3 hours. Weigh 66.69 g (0.3 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and the reaction is kept for 3 hours. Weigh 900 g (0.3 mol) of polyethylene glycol with a molecular weight of 3000 g / mol, slowly add it into the reaction kettle, the feeding time is 3 hours, and the reaction is kept for 4 hours. Weigh 66.69 g (0.3 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and the reaction is kept for 3 hours. Weigh 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com