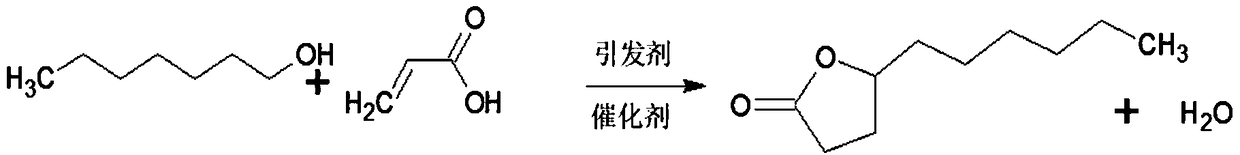

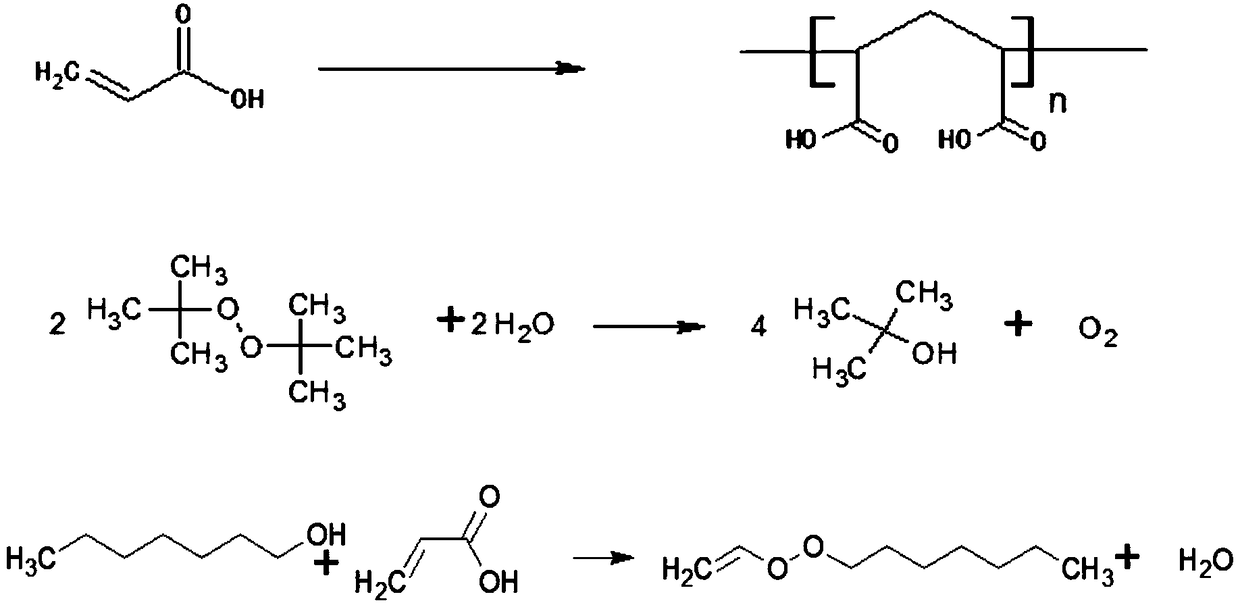

Production method of synthesizing gamma-decalactone synthetic perfume by reactive distillation

A technology for the synthesis of gamma-decalactone and fragrances, which is applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc. It can solve problems such as poor fuel consumption, decreased reaction yield, and prolonged reaction time, so as to save energy Effects of energy consumption, reduction of reaction time, and improvement of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of production method of reactive distillation synthesis gamma-decalactone synthesis fragrance, comprises the following steps:

[0046] a) From the heptanol head tank, methyl acrylate head tank and di-tert-butyl peroxide head tank respectively, using the high pressure difference, through the pipeline discharge, 1200kg of heptanol, 860kg of methyl acrylate and di-tert-butyl 140kg of base peroxide is added to the batching pot according to the batching ratio, and 15kg of sodium borohydride is added into the batching pot according to the batching ratio from the feeding port of the batching pot, and mixed evenly.

[0047] b) Use the high pressure difference from the heptanol head tank to discharge 3200kg heptanol into the preheater through the pipeline, and the preheater is heated to 150-180°C.

[0048] c) Put the heptanol in the preheater into the high-boiling point feed section of the reaction zone of the reactive distillation column through the material pump, and in...

Embodiment 2

[0057] The present embodiment produces gamma-decalactone synthetic perfume according to the method of Example 1. The difference is that in step (a), the addition of each material is: heptanol 1485kg, di-tert-butyl peroxide 85kg, boron Sodium hydride 8.5kg, methyl acrylate 1000kg;

[0058] In step (b), feed heptanol 4049kg;

[0059] All the other remain unchanged, and the gamma-decalactone product is prepared;

[0060] In the present embodiment, 288 kg of by-product tert-butanol and methanol are separated from the top of the rectifying section of the reactive distillation tower; 1339 kg of crude product of gamma decanolide is separated from the bottom of the reactive distillation tower;

[0061] Add water 670kg for washing;

[0062] Collect low-boiling impurities, by-product 2-octanone 27kg and residual heptanol 106kg that do not participate in the reaction;

[0063] After collecting the by-product heptyl acrylate 13kg, collect the gamma-position decanolactone, obtain the ga...

Embodiment 3

[0065] The present embodiment produces gamma-decalactone synthetic perfume according to the method of Example 1. The difference is that in step (a), the addition of each material is: heptanol 1822kg, di-tert-butyl peroxide 255kg, boron Sodium hydride 64kg, methyl acrylate 750kg;

[0066] In step (b), feed heptanol 5062kg;

[0067] All the other remain unchanged, and the gamma-decalactone product is prepared;

[0068] In the present embodiment, 392 kg of by-product tert-butanol and methyl alcohol are separated from the top of the rectifying section of the reactive distillation tower; 937 kg of the crude product of gamma-decalactone are separated from the bottom of the reactive distillation tower;

[0069] Add water 1405kg for washing;

[0070] Collect low-boiling point impurities, by-product 2-octanone 19kg and residual unreacted heptanol 88kg;

[0071] After collecting the by-product heptyl acrylate 10kg, collect the gamma decanolactone to obtain 816 kg of the gamma decanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com