A manufacturing method and application of lightweight battery negative electrode sheet

A battery anode, lightweight technology, used in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve the problems of production cost copper metal resource consumption, price rise and other problems, to improve repeatability, weight reduction, production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] A method for preparing a lightweight battery negative electrode sheet, comprising:

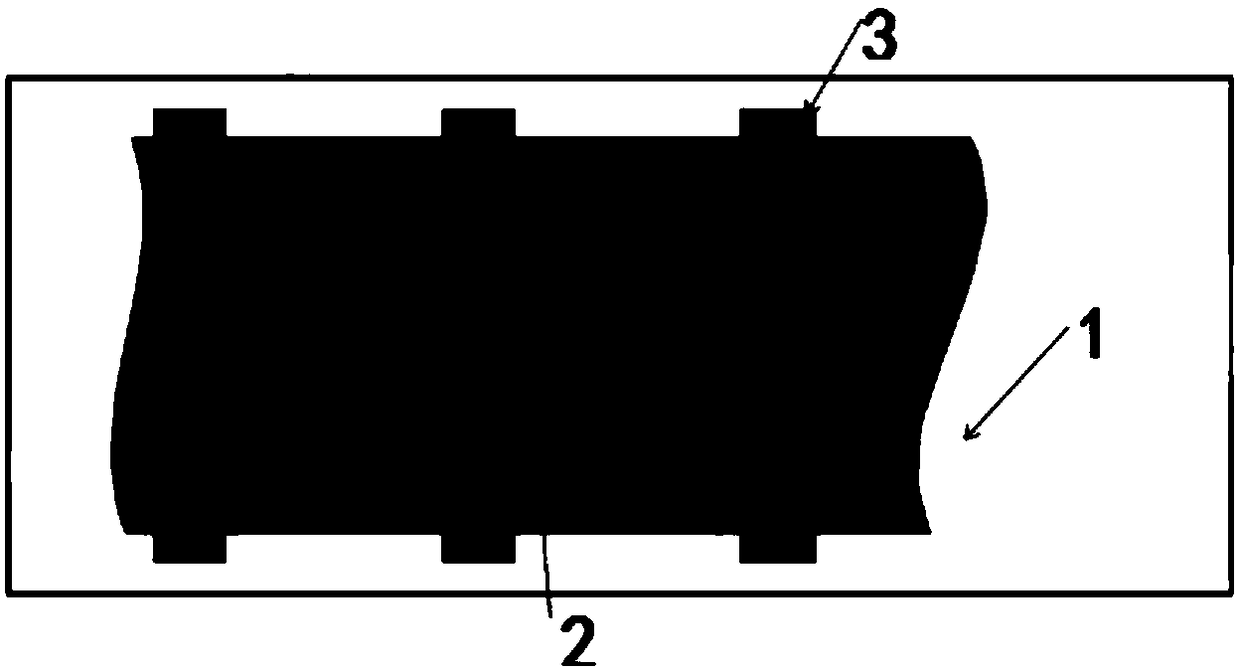

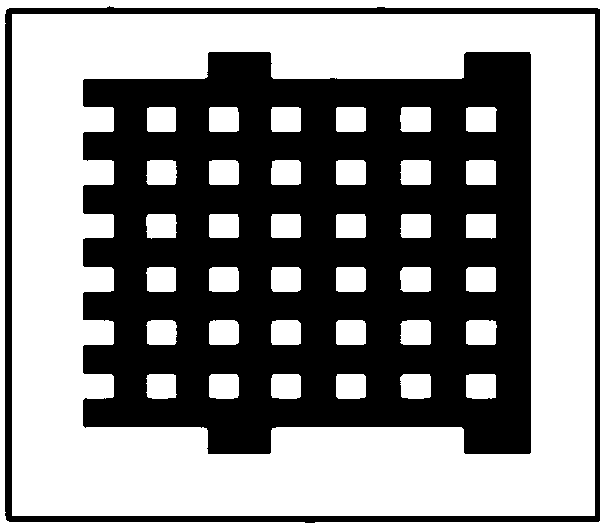

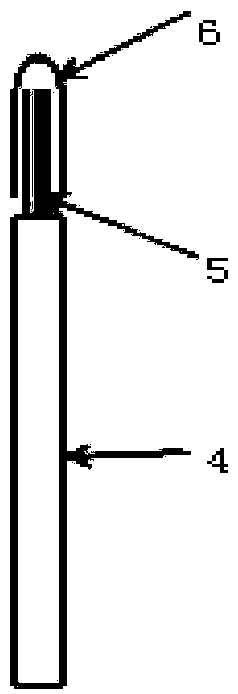

[0028] S1: Preparation of the negative electrode conductive substrate: select a polyester film (PET) with a specification of 10um*390mm and a hardness of 1HB. Print the grid pattern on the screen printing machine with 250-600 mesh screen, such as figure 2 As shown, the silk screen area is 10mm wide in both horizontal and vertical directions, and the blank area is a square with a side length of 10mm. A 2-5um thick acrylic glue solution is coated on the PET film 1, and is cured and dried by ultraviolet light. Put the PET film 1 on a smooth glass surface and fix it, then place the screen on the PET film 1 and press it tightly. The silver paste is scraped back and forth on the screen, the pattern on the screen is printed on the PET film 1, and dried at 60°C to obtain a conductive silver paste coating 3 with a thickness of 5um, and then the PET film 1 obtained above is pressed as follows ...

Embodiment 2

[0038] A method for preparing a lightweight battery negative electrode sheet, comprising:

[0039] S1: Preparation of the negative electrode conductive substrate: select a polyester film (PET) with a specification of 250um*390mm and a hardness of 1HB. Print the grid pattern on the screen printing machine with 250-600 mesh screen, such as figure 2 As shown, the silk screen area is 10mm wide in both horizontal and vertical directions, and the blank area is a square with a side length of 10mm. A 2-5um thick acrylic glue solution is coated on the PET film 1, and is cured and dried by ultraviolet light. Put the PET film 1 on a smooth glass surface and fix it, then place the screen on the PET film 1 and press it tightly. The silver paste is scraped back and forth on the screen, the pattern on the screen is printed on the PET film 1, and dried at 60°C to obtain a conductive silver paste coating 3 with a thickness of 20um, and then the PET film 1 obtained above is pressed as follow...

Embodiment 3

[0046] A method for preparing a lightweight battery negative electrode sheet, comprising:

[0047] S1: Preparation of the negative electrode conductive substrate: select a polyester film (PET) with a specification of 25um*390mm and a hardness of 1HB. Print the grid pattern on the screen printing machine with 250-600 mesh screen, such as figure 2 As shown, the silk screen area is 10mm wide in both horizontal and vertical directions, and the blank area is a square with a side length of 10mm. A 2-5um thick acrylic glue solution is coated on the PET film 1, and is cured and dried by ultraviolet light. Put the PET film 1 on a smooth glass surface and fix it, then place the screen on the PET film 1 and press it tightly. The silver paste is scraped back and forth on the screen, the pattern on the screen is printed on the PET film 1, and dried at 60°C to obtain a conductive silver paste coating 3 with a thickness of 15um, and then the PET film 1 obtained above is pressed as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com