Flexible electrode based on flower-like nanogold structure and preparation method thereof

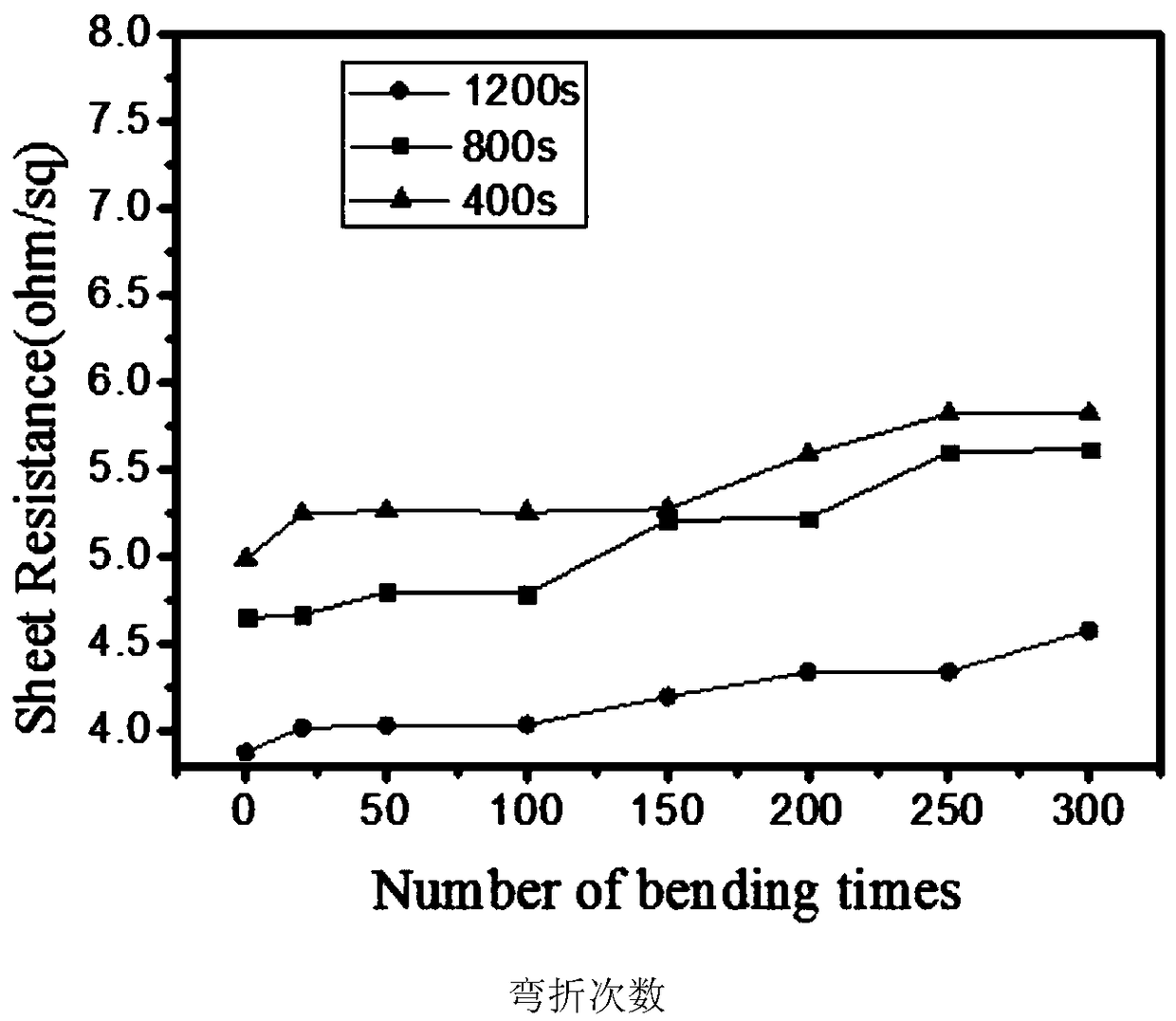

A flexible electrode and flower-like structure technology, applied in the field of flexible electrodes based on flower-like nano-gold structure and their preparation, can solve the problems of poor bending resistance and tensile resistance, and limit wide application, and achieve tensile resistance. and good bending resistance, overcoming difficulties, and reducing the effect of electrode resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

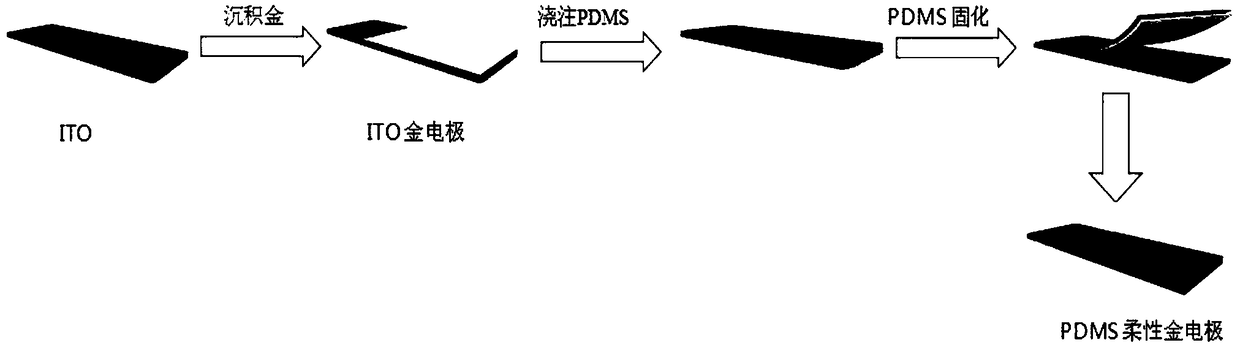

[0023] (1) Ultrasonic clean the ITO glass with absolute ethanol, then place it in a UV ozone cleaner for 30 minutes, then place the cleaned ITO with the conductive surface facing up, soak it in 5mg / mL PDDA solution for 5min, take it out , washed with distilled water several times in a small amount, and then blown dry with nitrogen.

[0024] (2) Using the same procedure, PSS assembly was performed on the ITO glass assembled with PDDA layer. After completion, a (PDDA / PSS) self-assembled layer can be produced. Repeat above-mentioned process 6 times, can prepare with (PDDA / PSS) 6 Multilayer self-assembled film of ITO glass. Finally, it was sealed in a petri dish with nitrogen gas for use.

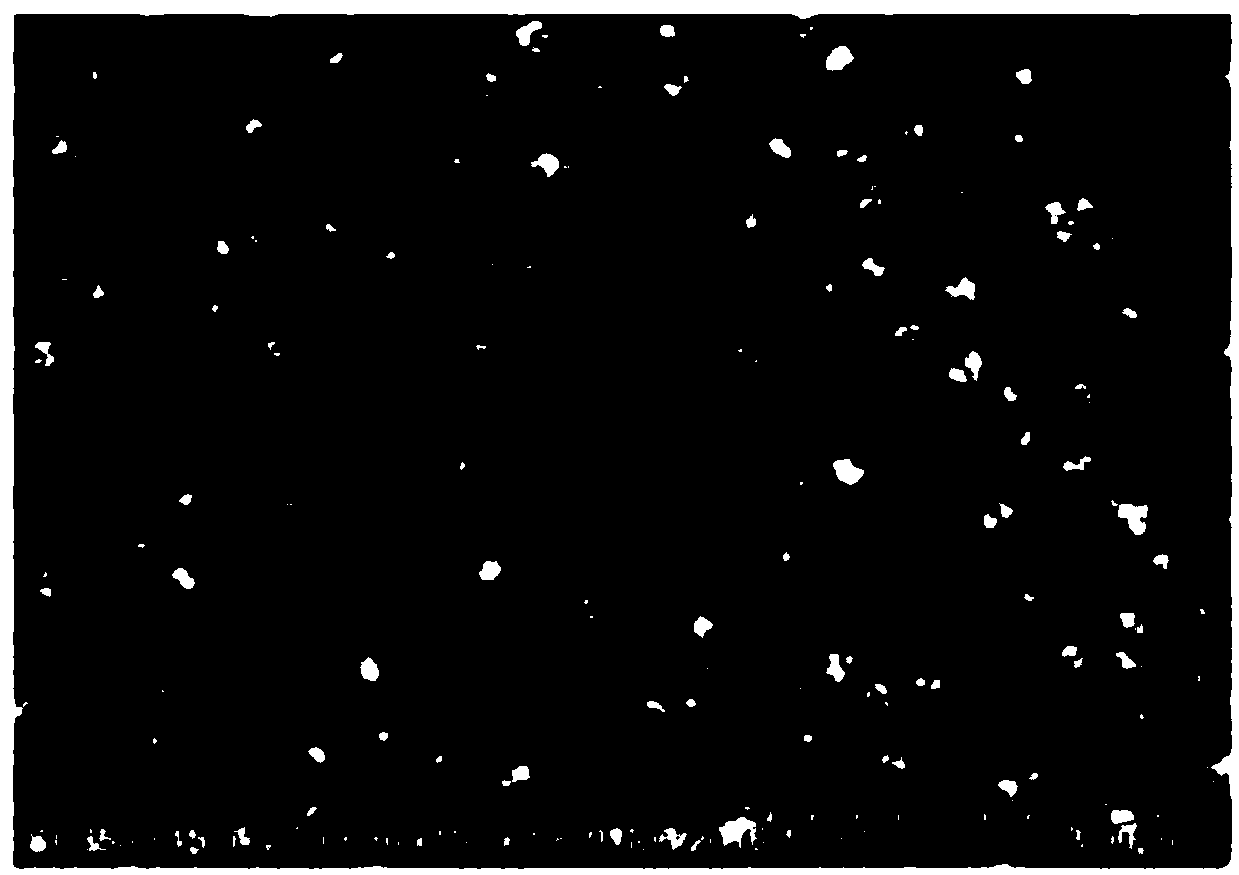

[0025] (3) Deposit flower-shaped nano-gold on the assembled ITO glass, the method adopted is chronoamperometry, the reference electrode is an Ag / AgCl electrode, the counter electrode is a platinum wire, and the working electrode is an assembled ITO glass. The solution is KAuCl 4 (0.01mol / L...

Embodiment 2

[0028] (1) Ultrasonic clean the ITO glass with absolute ethanol, then place it in a UV ozone cleaner for 30 minutes, then place the cleaned ITO with the conductive surface facing up, soak it in 5mg / mL PDDA solution for 5min, take it out , washed with distilled water several times in a small amount, and then blown dry with nitrogen.

[0029] (2) Using the same procedure, PSS assembly was performed on the ITO glass assembled with PDDA layer. After completion, a (PDDA / PSS) self-assembled layer can be produced. Repeat above-mentioned process 6 times, can prepare with (PDDA / PSS) 6 The ITO glass of the multilayer self-assembled film is finally sealed in a petri dish with nitrogen gas for use.

[0030] Deposit flower-shaped nano-gold on the assembled ITO glass, the method adopted is chronoamperometry, the reference electrode is Ag / AgCl electrode, the counter electrode is platinum wire, the working electrode is assembled ITO glass, and the electrolyte is KAuCl 4 (0.01mol / L) and H ...

Embodiment 3

[0033] (1) Ultrasonic clean the ITO glass with absolute ethanol, then place it in a UV ozone cleaner for 30 minutes, then place the cleaned ITO with the conductive surface facing up, soak it in 5mg / mL PDDA solution for 5min, take it out , washed with distilled water several times in a small amount, and then blown dry with nitrogen.

[0034] (2) Using the same procedure, PSS assembly was performed on the ITO glass assembled with PDDA layer. After completion, a (PDDA / PSS) self-assembled layer can be produced. Repeat above-mentioned process 6 times, can prepare with (PDDA / PSS) 6 The ITO glass of the multilayer self-assembled film is finally sealed in a petri dish with nitrogen gas for use.

[0035]Deposit flower-shaped nano-gold on the assembled ITO glass, the method adopted is chronoamperometry, the reference electrode is Ag / AgCl electrode, the counter electrode is platinum wire, the working electrode is assembled ITO glass, and the electrolyte is KAuCl 4 (0.01mol / L) and H 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com