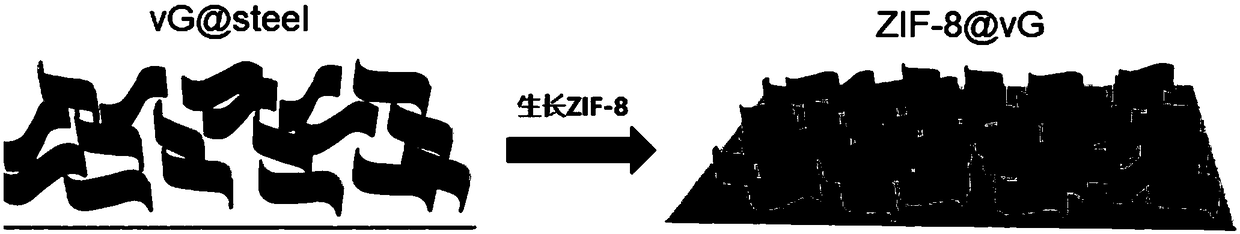

Electrochemical sensor based on metal organic framework-vertical graphene composite structure and preparation method thereof

A metal-organic framework and graphene composite technology, applied in the field of biosensors, can solve the problems of difficulty in performance improvement, relatively large performance limitations of electrochemical sensors, weak conductivity of transition metal complexes, etc., to achieve optimal sensing performance and conduction Performance, possibility of large space extension, effect of increasing adsorption point of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: electrochemical detection NO standard solution

[0054] (1) Using 4.0×10 containing 0.1M KCl -3 M Fe[(CN) 6 ] 3- / 4- The solution is an electrolyte, and the electrochemical properties of ZIF-8@vG electrode materials are characterized by cyclic voltammetry and electrochemical impedance spectroscopy;

[0055] (2) Using 2-(N,N-diethylamino)-diazene-2-oxysodium salt hydrate as a precursor to produce NO, prepare NO standard solution;

[0056] (3) Use the Griess test to determine the concentration of NO in the precursor solution: Nafion was coated on the surface of the ZIF-8@vG composite electrode to improve its specificity. Using cyclic voltammetry to detect different concentrations of NO standard solutions, after determining the best working potential, use chronoamperometry to detect a series of NO solutions with gradient concentrations.

[0057] (4) The electrochemical device constructed by Nafion-coated ZIF-8@vG composite working electrode was tested by a...

Embodiment 2

[0059] First, use polydimethylsiloxane (PDMS) to construct a small cell culture pool on the ZIF-8@vG substrate, and sterilize it with ultraviolet light for more than 30 minutes;

[0060] Then, respectively, will contain approximately 10 5 cells / mL The suspension of PC-12 cancer cells and common HEK-293 cells was added to the culture pool, using DMEM medium (containing 10% fetal bovine serum and 1% antibiotics), in a cell culture box with 5% CO 2 , cultured at 37°C to allow the cells to grow normally on the surface of the electrode material, and the chronoamperometry was used to test the ampere current response curve of the device after adding the polysaccharide solution.

[0061] Finally, cytotoxicity test: After the cells grow normally on the ZIF-8@vG substrate, they are stained with Calcein AM / PI staining agent to evaluate the viability of the cells and ensure that the electrode material will not be toxic to the cells.

Embodiment 3

[0063] (1) Grow vertical graphene on the metal microneedle array, and then prepare ZIF-8@vG nanocomposite structure;

[0064] (2) Integrate the endoscope with the electrochemical sensor-microneedle system to prepare an integrated insertable chip;

[0065] (3) Insert microneedles into mice with tumors, and monitor the concentration of NO in normal cells and cancer cells in the mice.

[0066] Detection of NO concentrations in different tissues and organ sites in mice;

[0067] (4) Effects of injection of different drugs on NO concentration in various tissues and organs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com