Special antibacterial textile fabric for infants and preparation method thereof

A technology for textile fabrics and babies, which is applied in the field of antibacterial textile fabrics for babies and its preparation, can solve problems such as lack of antibacterial functions, and achieve good market application prospects and good antibacterial capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

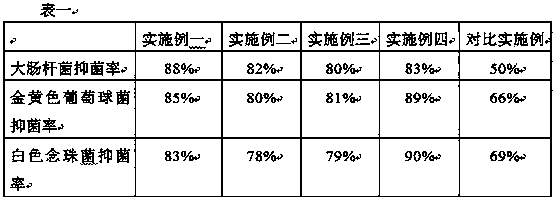

Examples

preparation example Construction

[0032] The present invention also proposes a preparation method of a baby-specific antibacterial textile fabric, wherein the method comprises the steps of:

[0033] (1) Add modal fiber, viscose fiber, acetate fiber, wool fiber and zein fiber to the drawing frame according to the corresponding preset weight ratio for mixing and processing to obtain cooked sliver.

[0034]Among them, the added modal fiber is 20-30 parts by weight, viscose fiber is 5-8 parts by weight, acetate fiber is 3-6 parts by weight, wool fiber is 40-50 parts by weight, corn The protein fiber has 15-20 parts by weight.

[0035] The above-mentioned modal fiber has a diameter of 41~43um and a fineness of 397~415dtex, a viscose fiber has a diameter of 42~44um and a fineness of 406~415dtex, and an acetate fiber has a diameter of 48~49um and a fineness of 415~422dtex. Among them, the cellulose acetate is diacetate spinning grade cellulose acetate. The above-mentioned wool fiber has a diameter of 30-35um and a ...

Embodiment 1

[0044] (1) Add modal fiber, viscose fiber, acetate fiber, wool fiber and zein fiber to the drawing frame according to the corresponding preset weight ratio for mixing and processing to obtain cooked sliver.

[0045] Wherein, the weight portion of the modal fiber that adds is 20 parts, the weight portion of viscose fiber is 3 parts, the weight portion of acetate fiber is 3 parts, the weight portion of wool fiber is 40 parts, the weight portion of zein fiber is 20 parts .

[0046] The modal fiber has a diameter of 41um and a fineness of 397dtex, the viscose fiber has a diameter of 42um and a fineness of 406dtex, and the acetate fiber has a diameter of 48um and a fineness of 415dtex. Among them, the cellulose acetate is diacetate spinning grade cellulose acetate. The above-mentioned wool fiber has a diameter of 30um and a fineness of 407dtex. The zein fiber has a diameter of 33um and a fineness of 411dtex.

[0047] (2) Use a roving frame to stretch the cooked sliver to obtain ...

Embodiment 2

[0055] (1) Add modal fiber, viscose fiber, acetate fiber, wool fiber and zein fiber to the drawing frame according to the corresponding preset weight ratio for mixing and processing to obtain cooked sliver.

[0056] Wherein, the weight portion of the modal fiber that adds is 30 parts, and the weight portion of viscose fiber is 8 parts, and the weight portion of acetate fiber is 6 parts, and the weight portion of wool fiber is 50 parts, and the weight portion of zein fiber is 20 parts .

[0057] The modal fiber has a diameter of 43um and a fineness of 415dtex, the viscose fiber has a diameter of 44um and a fineness of 415dtex, and the acetate fiber has a diameter of 49um and a fineness of 422dtex. Among them, the cellulose acetate is diacetate spinning grade cellulose acetate. The above-mentioned wool fiber has a diameter of 35um and a fineness of 425dtex. The zein fiber has a diameter of 36um and a fineness of 423dtex.

[0058] (2) Use a roving frame to stretch the cooked s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com