Processing technology of antibacterial aerated brick

A processing technology and technology of aerated bricks, used in applications, household appliances, ceramic products, etc., can solve the problem that aerated bricks do not have antibacterial functions, and achieve good bacteriostatic effect, increase compressive strength, and inhibit mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

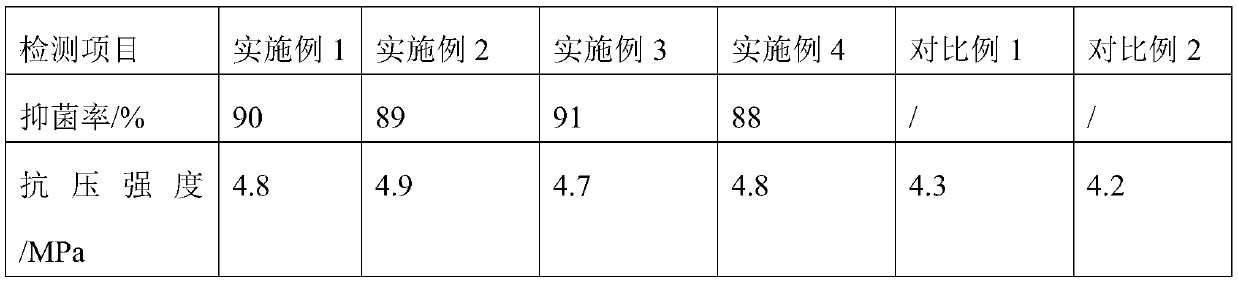

Examples

Embodiment 1

[0020] Embodiment 1, a kind of processing technology of antibacterial aerated brick, comprises the following steps:

[0021] 1) Weigh 70 parts of fly ash, 15 parts of quicklime, 10 parts of cement, 10 parts of gypsum, 9 parts of aluminum powder paste, 8 parts of montmorillonite powder, 6-8 parts of traditional Chinese medicine slag, and 5 parts by weight of steel fiber 12 parts by weight of copper-containing aluminum phosphate, wherein Chinese medicinal dregs contain Coptidis Rhizome, Scutellaria baicalensis and clove, the content of these three Chinese medicinal ingredients in medicinal dregs is more than 30%, and the diameter of steel fibers is 0.08-0.2mm;

[0022] 2) Mix coal ash, quicklime, cement, gypsum, montmorillonite powder, and steel fiber, then add water, mix evenly, add aluminum powder paste to obtain slurry,

[0023] 3) Inject the stirred slurry into the mould, then put it into the resting room and seal it at 55-60°C for heat preservation, resting for 1.8-2 hours,...

Embodiment 2

[0026] Embodiment 2, a kind of processing technique of antibacterial aerated brick, comprises the following steps:

[0027] 1) Weigh 60 parts of fly ash, 10 parts of quicklime, 10 parts of cement, 5 parts of gypsum, 8 parts of aluminum powder paste, 5 parts of montmorillonite powder, 6-8 parts of traditional Chinese medicine slag, and 3 parts by weight of steel fiber 10 parts by weight of copper-containing aluminum phosphate, wherein the traditional Chinese medicine residue contains star anise and rhubarb, the content of these two traditional Chinese medicine ingredients in the medicinal residue is more than 40%, and the diameter of the steel fiber is 0.08-0.2mm;

[0028] 2) Mix coal ash, quicklime, cement, gypsum, montmorillonite powder, and steel fiber, then add water, mix evenly, add aluminum powder paste to obtain slurry,

[0029] 3) Inject the stirred slurry into the mould, then put it into the resting room and seal it at 55-60°C for heat preservation, resting for 1.8-2 h...

Embodiment 3

[0032] Embodiment 3, a kind of processing technology of antibacterial aerated brick, comprises the following steps:

[0033] 1) Weigh 80 parts of fly ash, 15 parts of quicklime, 15 parts of cement, 12 parts of gypsum, 9 parts of aluminum powder paste, 8 parts of montmorillonite powder, 6-8 parts of traditional Chinese medicine slag, and 6 parts by weight of steel fiber 12 parts by weight of copper-containing aluminum phosphate, wherein the dregs of traditional Chinese medicines contain Coptis chinensis, Scutellaria baicalensis and rhubarb, the content of these three traditional Chinese medicine ingredients in the dregs of Chinese medicines is more than 30%, and the diameter of the steel fibers is 0.08-0.2mm;

[0034] 2) Mix coal ash, quicklime, cement, gypsum, montmorillonite powder, and steel fiber, then add water, mix evenly, add aluminum powder paste to obtain slurry,

[0035] 3) Inject the stirred slurry into the mould, then put it into the resting room and seal it at 55-6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com