High-strength paint and preparation method thereof

A high-strength, coating technology, applied in polyamide coatings, epoxy resin coatings, coatings, etc., can solve the problems of low strength, low hardness, difficult material protection, etc., to improve service life, high strength and hardness, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

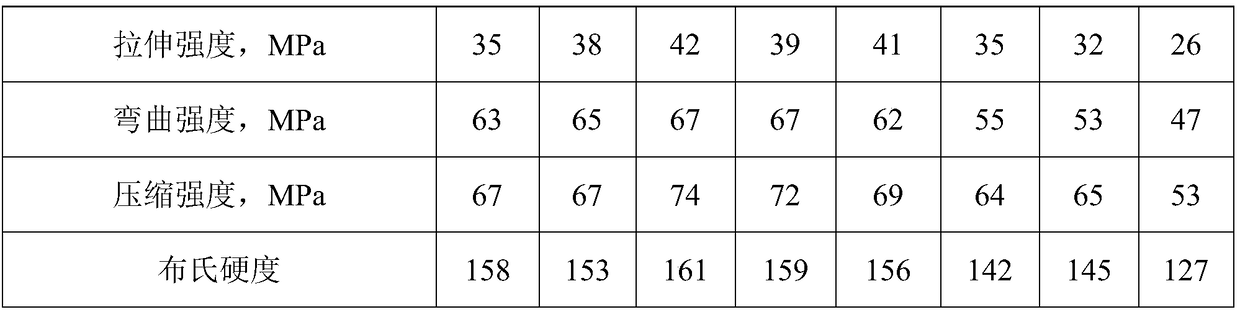

Examples

Embodiment 1

[0021] A high-strength paint, comprising the following raw materials in parts by weight: 30 parts of epoxy resin, 10 parts of acrylic emulsion, 10 parts of polybutylene adipamide, 2 parts of triisooctyl phosphite, 1 part of vitrified microbeads 3 parts, 3 parts of glass fiber, 3 parts of diamond powder, 5 parts of silane coupling agent, 20 parts of polyethylene glycol, 3 parts of methyl tributylketoxime silane, 2-hydroxy-4-n-octyloxybenzidine 2 parts of ketone, 1 part of film-forming aid, 2 parts of adhesive, 30 parts of deionized water.

[0022] Wherein, the acrylic emulsion is composed of pure acrylic emulsion, silicon acrylic emulsion and vinegar acrylic emulsion in a weight ratio of 1:3:2.

[0023] Wherein, the glass fiber is an alkali-free glass fiber with a length of 0.8 mm and a diameter of 2 μm.

[0024] After the paint is applied and dried, it is irradiated with ultraviolet rays for 3 minutes, and the ultraviolet intensity is 300 μW / cm^2.

[0025] In the present emb...

Embodiment 2

[0030] A high-strength paint, comprising the following raw materials in parts by weight: 35 parts of epoxy resin, 12 parts of acrylic emulsion, 12 parts of polybutylene adipamide, 3 parts of triisooctyl phosphite, 1.2 parts of vitrified microbeads 4 parts, 4 parts of glass fiber, 4 parts of diamond powder, 8 parts of silane coupling agent, 35 parts of polyethylene glycol, 5 parts of methyl tributylketoxime silane, 2-hydroxy-4-n-octyloxybenzidine 5 parts of ketones, 1.8 parts of film-forming aids, 2.8 parts of adhesives, and 45 parts of deionized water.

[0031] Wherein, the acrylic emulsion is composed of pure acrylic emulsion, silicon acrylic emulsion and vinegar acrylic emulsion in a weight ratio of 1:3:2.

[0032] Wherein, the glass fiber is an alkali-free glass fiber with a length of 1.2 mm and a diameter of 3 μm.

[0033] After the paint is applied and dried, it is irradiated with ultraviolet rays for 4 minutes, and the ultraviolet intensity is 400 μW / cm^2.

[0034] In ...

Embodiment 3

[0039] A high-strength paint, comprising the following raw materials in parts by weight: 40 parts of epoxy resin, 15 parts of acrylic emulsion, 15 parts of polybutylene adipamide, 3.5 parts of triisooctyl phosphite, 1.5 parts of vitrified microbeads 4.5 parts of glass fiber, 4.5 parts of diamond powder, 7 parts of silane coupling agent, 30 parts of polyethylene glycol, 4.5 parts of methyl tributylketoxime silane, 2-hydroxy-4-n-octyloxydiphenylmethane 4 parts of ketones, 1.5 parts of film-forming aids, 2.5 parts of adhesives, and 40 parts of deionized water.

[0040] Wherein, the acrylic emulsion is composed of pure acrylic emulsion, silicon acrylic emulsion and vinegar acrylic emulsion in a weight ratio of 1:3:2.

[0041] Wherein, the glass fiber is an alkali-free glass fiber with a length of 1.2 mm and a diameter of 3 μm.

[0042] After the paint is applied and dried, it is irradiated with ultraviolet rays for 4 minutes, and the ultraviolet intensity is 400 μW / cm^2.

[0043...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com