Multilayered compound yoga mat and production process thereof

A multi-layer composite and yoga mat technology, which is applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of poor comfort and softness of yoga

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] 1) Preparation of PP / EPDM masterbatch

[0088] a. Weigh polypropylene resin PP, EPDM EPDM, dicumyl peroxide DCP, vulcanizing agent, auxiliary crosslinking agent, composite antioxidant and activated carbon according to the ratio of raw materials of the above-mentioned PP / EPDM substrate ;

[0089] b. First, dry the polypropylene resin PP and EPDM at a temperature of 70-90°C for 2-4 hours, and then dry the dicumyl peroxide DCP, vulcanizing agent, co-crosslinking agent, and composite antioxidant Fully mix with activated carbon in a high-speed mixer to obtain a mixture, and then add the dried polypropylene resin PP and EPDM and the mixture to the internal mixer to fully mix, and single-screw extrusion granulation to obtain PP / EPDM masterbatch;

[0090] 2) Preparation of POE foam substrate

[0091] a. Take by weighing ethylene-octene copolymer POE, polyethylene, ethylene-vinyl acetate copolymerized EVA, foaming agent, modifier and composite antioxidant by weight and number ...

Embodiment 1

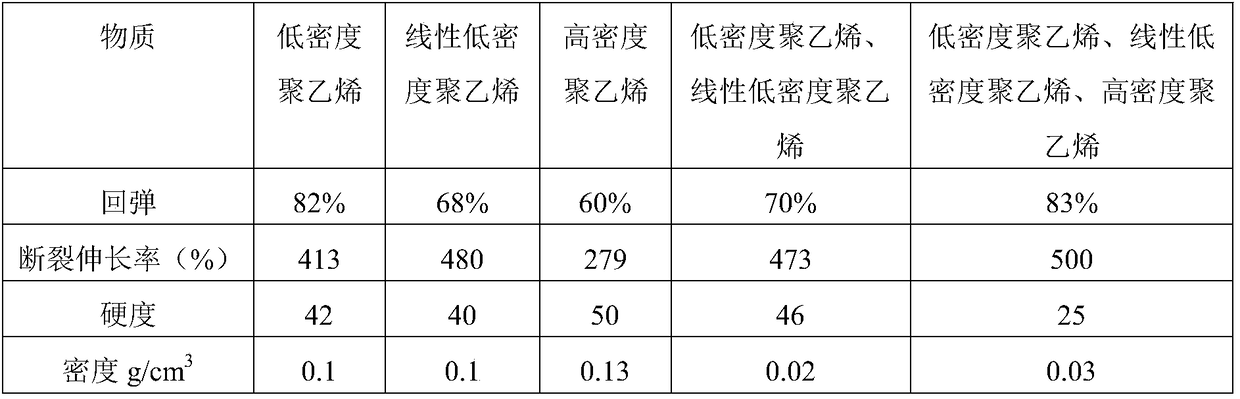

[0178] Multi-layer composite yoga mat 1, said multi-layer composite yoga mat 1 comprises polyethylene foam layer, POE foam layer and PP / EPDM substrate successively from top to bottom, wherein,

[0179] The raw materials of the PP / EPDM substrate include 60 parts by weight of polypropylene resin PP, 40 parts of EPDM terpolymer, 1.5 parts of dicumyl peroxide DCP, 2 parts of vulcanizing agent, 6 parts Auxiliary cross-linking agent, 0.8 parts of composite antioxidant and 1.2 parts of activated carbon; wherein,

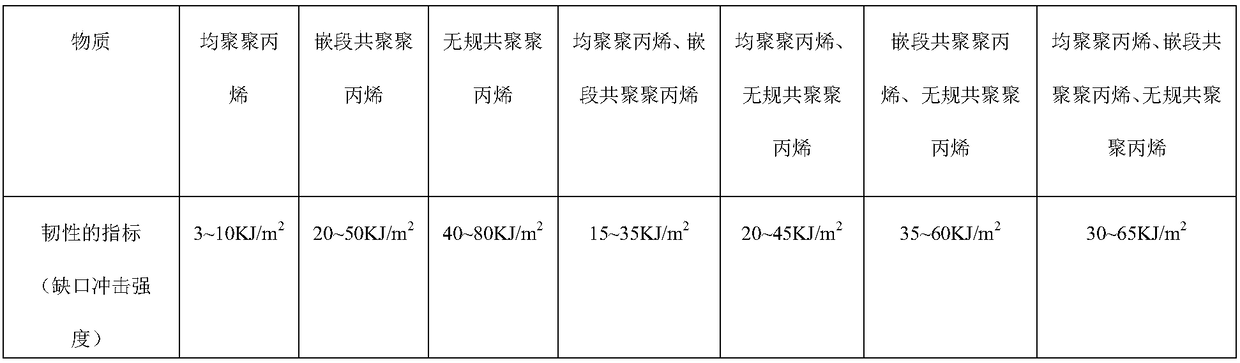

[0180] Polypropylene resin PP is composed of homopolypropylene, block copolymerized polypropylene and random copolymerized polypropylene, wherein the weight ratio of homopolypropylene, block copolymerized polypropylene and random copolymerized polypropylene is 1:3:6; The melting temperature (DSC) of polypropylene resin PP is 145-195°C, and the melt flow rate is 1.0-3.0g / 10min;

[0181] The vulcanizing agent is composed of sulfur and phenolic resin, wherein the weight ratio...

Embodiment 2

[0213] Multi-layer composite yoga mat 2, it comprises polyethylene foam layer, POE foam layer and PP / EPDM substrate successively from top to bottom, wherein,

[0214] The raw materials of the PP / EPDM substrate include 30 parts of homopolypropylene, 70 parts of EPDM, 1.6 parts of dicumyl peroxide DCP, 1 part of phenolic resin, 5 parts Pentaerythritol triacrylate, 2 parts of composite antioxidant and 1 part of activated carbon;

[0215] Wherein, in the compound antioxidant, the weight ratio of antioxidant 1010 and antioxidant DSTP is 2:1;

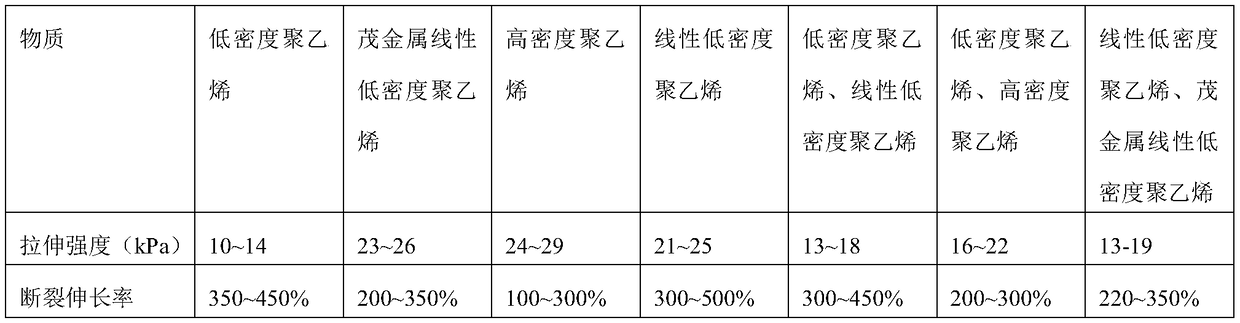

[0216] The raw materials of the POE foam layer include 70 parts by weight of ethylene-octene copolymer POE, 10 parts of mixed low-density polyethylene, 10 parts of ethylene-vinyl acetate copolymerized EVA, and 1 part of POE layer hair. Foaming agent, 2 parts of zinc acetate and 0.5 part of composite antioxidant;

[0217] Among them, mixed low-density polyethylene is formed by mixing low-density polyethylene and linear low-density polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com