Two-dimensional ultra-thin SAPO-34 molecular sieve sheeting material and preparation method thereof

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, nanotechnology for materials and surface science, etc., to achieve no environmental pollution, universal method and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

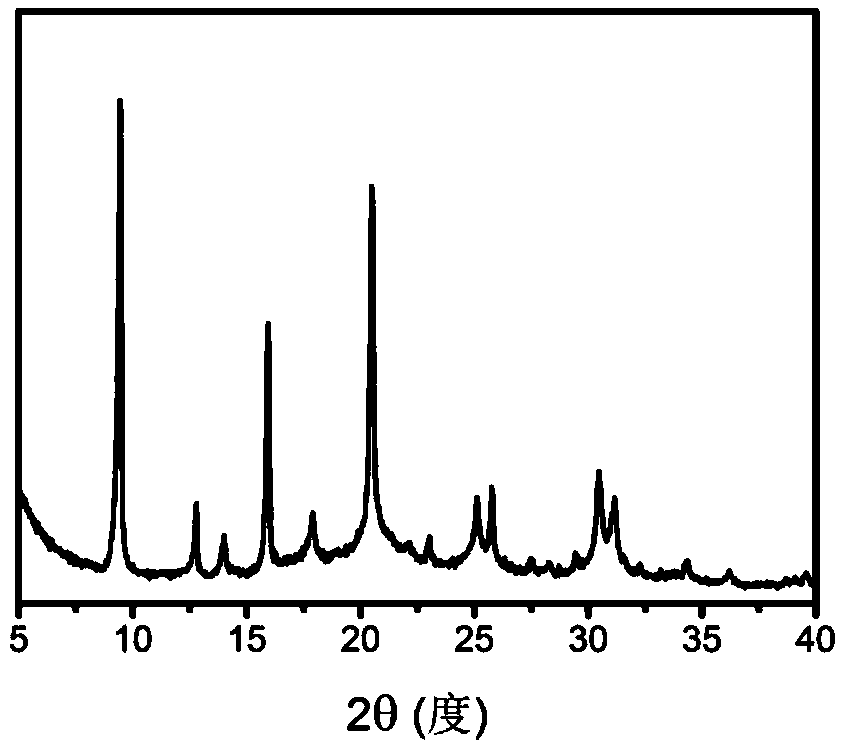

[0029] Get 0.500 gram of aluminum phosphate nano-volume powder, add 0.050 gram of tetraethyl orthosilicate and 0.550 gram of methanol, stir at room temperature into a uniform paste, leave it for 24 hours; after that, add 0.100 gram of tetraethylammonium hydroxide (25% ) solution, stirred into a uniform paste, and left for 24 hours; after that, it was transferred to a hydrothermal kettle with 0.100 gram of water, 0.200 gram of tetraethylammonium hydroxide (25%) solution and 0.400 gram of triethylamine In the polytetrafluoroethylene lining, seal; after that, hydrothermal at 160 ° C for 72 hours; after that, naturally cool to room temperature, filter to obtain the precipitate, and use water and absolute ethanol to wash the precipitate several times, and dry at 60 ° C for 24 hours , to obtain a dry white powder; then, put the obtained white powder into a muffle furnace, and raise the temperature from room temperature to 550° C. under an air atmosphere, and keep it for 5 hours. Fin...

Embodiment 2

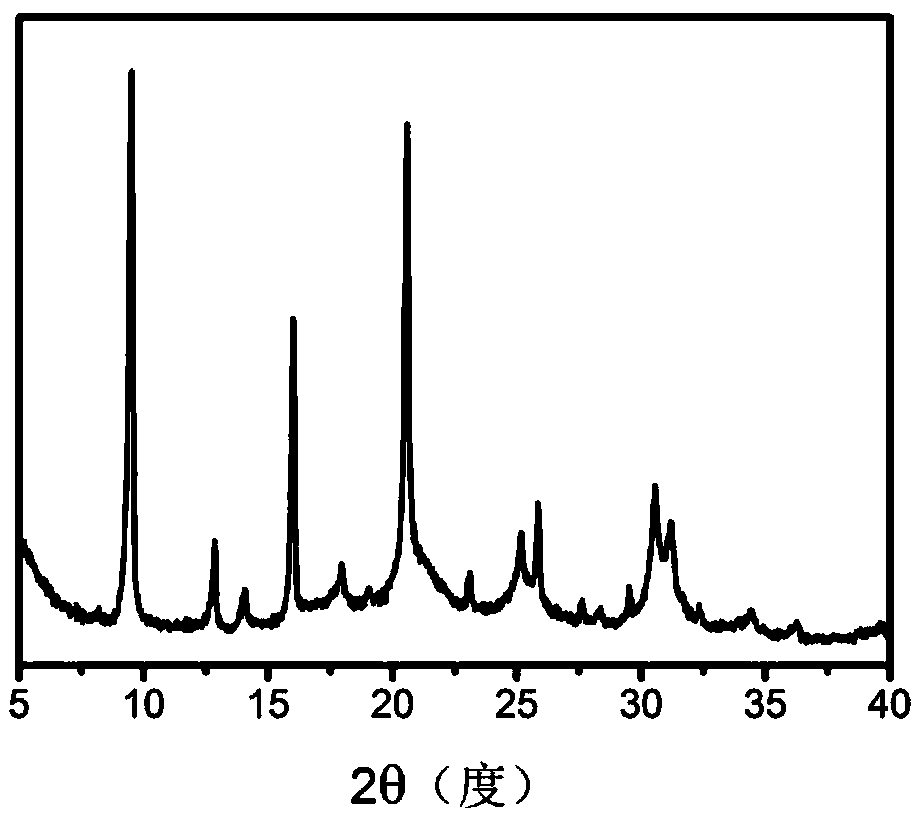

[0032] Get 1.000 gram of aluminum phosphate nano-volume powder, add 0.500 gram of tetraethyl orthosilicate and 0.700 gram of ethanol, stir into a uniform paste at room temperature, and leave it for 24 hours; after that, add 0.400 gram of tetraethylammonium hydroxide (25% ) solution, stirred into a uniform paste, and left for 24 hours; after that, it was transferred to a hydrothermal kettle with 0.400 gram of water, 0.800 gram of tetraethylammonium hydroxide (25%) solution and 2.000 gram of triethylamine In the polytetrafluoroethylene lining, seal; after that, hydrothermal at 180 ° C for 48 hours; after that, naturally cool to room temperature, filter to obtain the precipitate, and use water and absolute ethanol to wash the precipitate several times, and dry at 60 ° C for 24 hours , to obtain a dry white powder; then, put the obtained white powder into a muffle furnace, and raise the temperature from room temperature to 550° C. under an air atmosphere, and keep it for 5 hours. ...

Embodiment 3

[0035] Get 2.000 grams of aluminum phosphate nanovolume powder, add 0.40 grams of tetrapropyl orthosilicate and 2.000 grams of methanol, stir at room temperature into a uniform paste, and leave it for 24 hours; after that, add 0.500 grams of tetraethylammonium hydroxide (25% ) solution, stirred into a uniform paste, and left for 24 hours; after that, it was transferred to a hydrothermal kettle with 0.600 grams of water, 1.000 grams of tetraethylammonium hydroxide (25%) solution and 2.400 grams of triethylamine In the polytetrafluoroethylene lining, seal; after that, 200 ℃ water heating for 20 hours; after that, naturally cool to room temperature, filter to get the precipitate, and use water and absolute ethanol to wash the precipitate several times, and dry at 60 ℃ for 24 hours , to obtain a dry white powder; then, put the obtained white powder into a muffle furnace, and raise the temperature from room temperature to 550° C. under an air atmosphere, and keep it for 5 hours. Fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com