Preparation method for super-hydrophobic bamboo/wood

A technology of wood and water bamboo, which is applied in the field of superhydrophobic bamboo/wood preparation, can solve problems such as single method, high cost, and unstable structure, and achieve the effect of high surface roughness, high static contact angle, and excellent waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

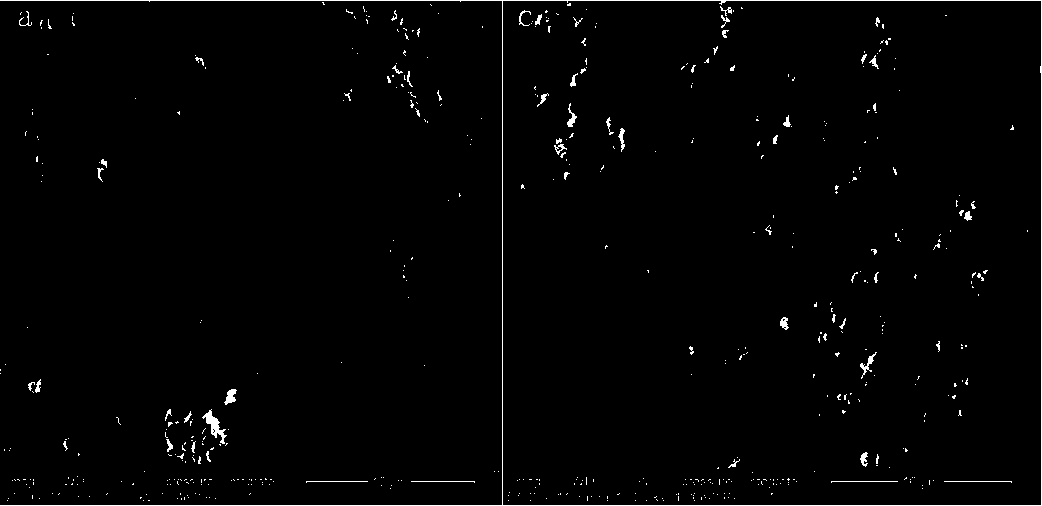

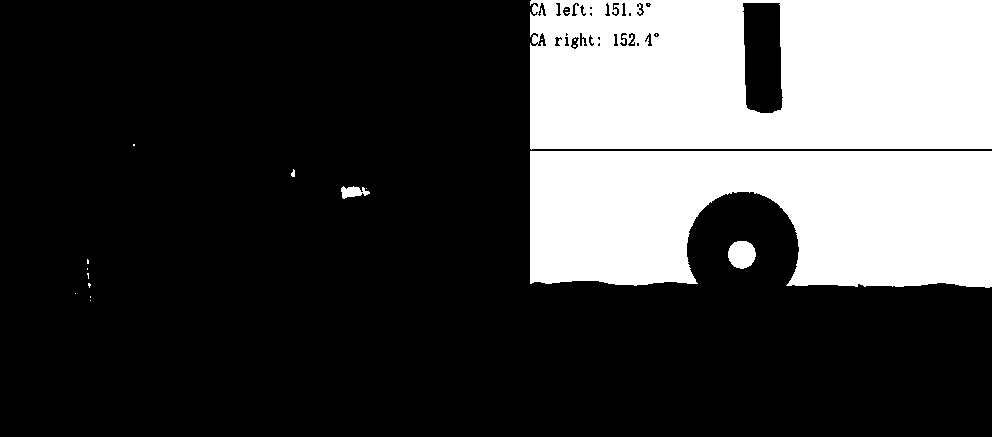

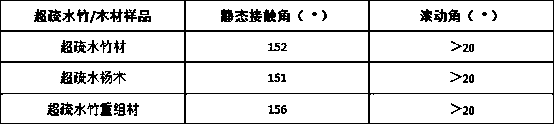

Image

Examples

preparation example Construction

[0017] A preparation method of superhydrophobic bamboo / wood, comprising the following steps:

[0018] (1) Dry the bamboo and wood until the water content is 6-8%, then immerse them in a toluene-ethanol mixture with a mass ratio of (1-3):1 and vacuum soak for 24 hours, take them out and dry them to dryness, and then Ultrasonic cleaning in absolute ethanol for 15 to 30 minutes, and finally vacuum drying at 80 to 100°C for 1 to 2 hours, and put it in a vacuum desiccator for later use;

[0019] (2) Add 0.02M zinc acetate dihydrate crystal particles into 300mL diethylene glycol, stir at room temperature until completely dissolved, stir and heat to 160°C, keep constant temperature reaction for 4 hours, stop, cool to room temperature, and centrifuge to obtain ZnO nanoparticles, then ultrasonically cleaned with absolute ethanol for 10-20 minutes, repeating the above process 2-4 times, finally centrifuged and dried to obtain spherical ZnO nanoparticles with a diameter of 100-200nm;

...

Embodiment 1

[0029] A preparation method of superhydrophobic bamboo, comprising:

[0030] (1) Dry the bamboo to a moisture content of 8%, then immerse it in a toluene-ethanol mixture (mass ratio: 2:1) and vacuum soak for 24 hours, take it out, dry it to absolute dryness, and then ultrasonically clean it in absolute ethanol for 15 minutes , and finally vacuum-dried at 80°C for 2 hours, and placed in a vacuum desiccator for later use;

[0031] (2) Add 0.02M zinc acetate dihydrate crystal particles into 300mL diethylene glycol, stir at room temperature until completely dissolved, stir and heat to 160°C, keep constant temperature for 4 hours, stop, cool to room temperature and centrifuge to obtain ZnO nanoparticles were then ultrasonically cleaned with absolute ethanol for 15 minutes, and this process was repeated three times, and finally centrifuged and dried to obtain spherical ZnO nanoparticles with a diameter of 100-200 nm;

[0032] (3) Disperse the spherical ZnO nanoparticles prepared in...

Embodiment 2

[0037] A preparation method of super-hydrophobic poplar wood, comprising:

[0038] (1) Dry the poplar wood to a moisture content of 6%, then immerse it in a toluene-ethanol mixture (mass ratio: 3:1) and vacuum soak for 24 hours, take it out, dry it until it is absolutely dry, and then ultrasonically clean it in absolute ethanol 10min, and finally vacuum-dried at 80°C for 2h, and placed in a vacuum desiccator for later use;

[0039] (2) Add 0.02M zinc acetate dihydrate crystal particles into 300mL diethylene glycol, stir at room temperature until completely dissolved, stir and heat to 160°C, keep constant temperature reaction for 4 hours, stop, cool to room temperature, and centrifuge to obtain ZnO nanoparticles, then ultrasonically cleaned with absolute ethanol for 15 minutes, repeating this process 3 times, finally centrifuged and dried to obtain spherical ZnO nanoparticles with a diameter of 100-200nm;

[0040] (3) Disperse the spherical ZnO nanoparticles prepared in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com