Nonlinear Optical Devices Containing Peroborite Crystals

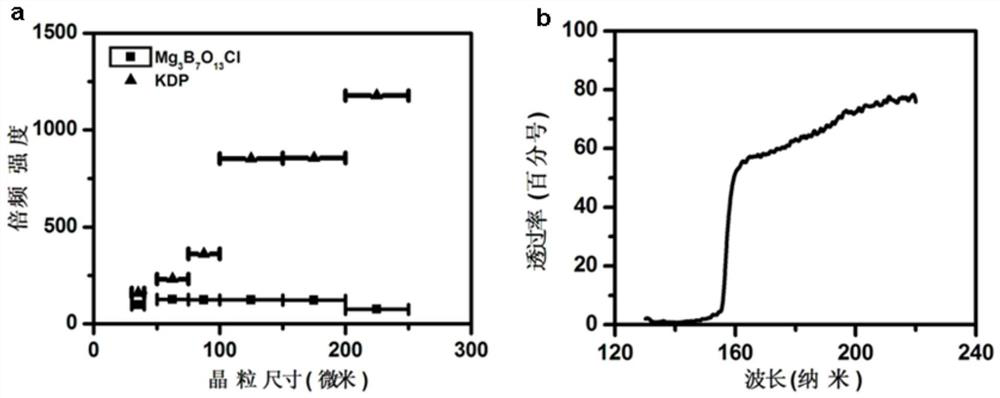

A technology of nonlinear optics and boronite, which is applied in the field of nonlinear optical devices containing boronite crystals, and can solve problems such as the difficulty of deep ultraviolet nonlinear optical crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 molten salt method grows boborite crystal

[0067] (1) Pre-calcined boronite: using analytically pure MgCl 2 、H 3 BO 3 As the initial raw material, according to Mg 3 B 7 o 13 Cl stoichiometry, MgCl 2 and H 3 BO 3 Excess 1wt% and 3wt% respectively carry out weighing, mixing, grinding, tabletting, and then put into a furnace, and pre-fire at 800-900° C. for two hours.

[0068] (2) crystal growth: adopt molten salt method to grow boborite crystal, comprise the following steps: pre-burned boborite and flux (flux is MgCl 2 and H 3 BO 3 According to the mixture of 1:1 in molar ratio, to ensure that the impurity phase is not introduced), weigh and mix according to the molar ratio of 1:1, put it into a platinum crucible, put the crucible into the center of the molten salt furnace, and cover the furnace cover; The temperature was raised to 1200°C at a rate of 50°C per hour, melted, and kept for two days, then lowered to room temperature at a rate of 50°C ...

Embodiment 2

[0069] Embodiment 2 molten salt method grows boborite crystal

[0070] (1) Pre-calcined boronite: using analytically pure MgO, MgCl 2 、H 3 BO 3 As the initial raw material, according to Mg 3 B 7 o 13 Cl stoichiometric ratio, MgO, MgCl 2 and H 3 BO 3 Weigh, where MgCl 2 and H 3 BO 3 Excessive 3wt% and 5wt%, respectively, mixed, ground, pressed into a furnace, and pre-fired at 800-900°C for two hours.

[0071] (2) crystal growth: adopt molten salt method to grow boborite crystal, comprise the following steps: pre-burned boborite and flux (flux is MgCl 2 and H 3 BO 3 According to the molar ratio of 3:1 mixture), weigh and mix according to the molar ratio of 1:2, put it into a platinum crucible, put the crucible in the center of the molten salt furnace, and cover the furnace cover; heat up at a rate of 50°C per hour Melt at 1180°C, keep warm for two days, then cool down to room temperature at a rate of 50°C per hour, wash with water, and obtain boronite crystals.

Embodiment 3

[0072] Embodiment 3 molten salt method grows boborite crystal

[0073] (1) Pre-calcined boronite: using analytically pure MgCl 2 、H 3 BO 3 As the initial raw material, according to Mg 3 B 7 o 13 Cl stoichiometric ratio, MgCl 2 and B 2 o 3 Weigh, where MgCl 2 Excess 2wt%, after mixing, grinding and tableting, put into furnace, and pre-fire at 800-900°C for two hours.

[0074] (2) crystal growth: adopt molten salt method to grow boborite crystal, comprise the following steps: pre-burned boborite and flux (flux is MgCl 2 and H 3 BO 3 According to the molar ratio of 3:1 mixture), weigh and mix according to the molar ratio of 1:4, put it into a platinum crucible, put the crucible in the center of the molten salt furnace, cover the furnace cover; heat up at a rate of 50 ° C per hour Melt at 1150°C, keep warm for two days, then cool down to room temperature at a rate of 50°C per hour, wash with water, and obtain boronite crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com