Cell culture plate for analyzing biological function of bone

A cell culture and functional analysis technology, applied in animal cells, cell culture supports/coatings, vertebrate cells, etc., can solve the problems of limiting cell differentiation and functional research, expensive products, etc., to improve osteoinductive effect and The ability to carry cells, excellent biocompatibility, and the effect of thin coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

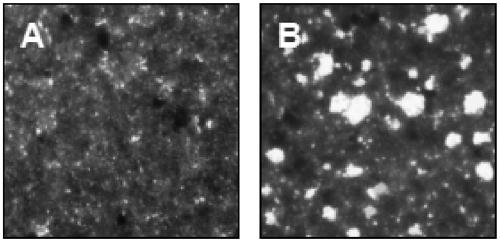

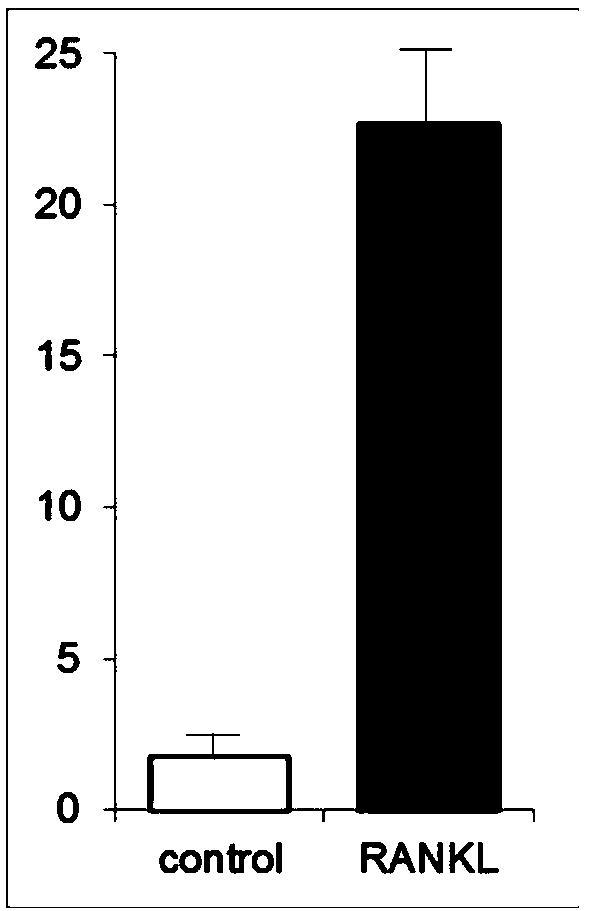

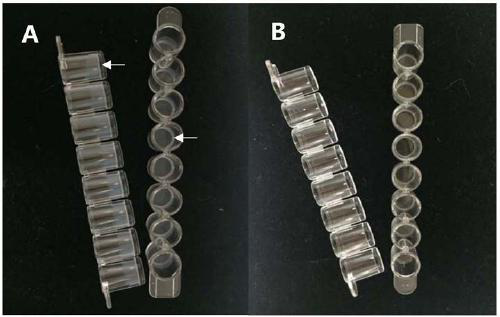

[0029] Anhydrous calcium hydrogen phosphate and calcium carbonate with a weight ratio of 136.06:100.09 are calcined at 1500°C to form tetracalcium phosphate, which is ground, stirred and sieved to obtain tetracalcium phosphate particles with a diameter of 1-80 μm. Grinding, stirring and sieving to obtain calcium hydrogen phosphate particles with a diameter of 0.4-3.0 μm. Tetracalcium phosphate (MW=366.254g / mol) / calcium hydrogen phosphate (MW=136.057g / mol) is mixed in a molar mass ratio of 1 / 3 to prepare calcium phosphate composite powder, and 1%-5% of mass percentage of citric acid tri Sodium, building bone substitute material. ddH 2 O (2.5% W / V) double distilled water was used as the liquid phase. Add 100mLddH to 250mg bone substitute material 2 O (2.5% W / V) double distilled water to obtain 2.5mg / mL bone substitute material stock solution, ultrasonically stirred (50% vibration amplitude, 20 seconds) to form a uniform bone substitute material suspension, measure the microsp...

Embodiment 2

[0031] Anhydrous calcium hydrogen phosphate and calcium carbonate with a weight ratio of 136.06:100.09 are calcined at a high temperature of 1400°C to form tetracalcium phosphate, which is ground, stirred and sieved to obtain tetracalcium phosphate particles with a diameter of 1-80 μm. Grinding, stirring and sieving to obtain calcium hydrogen phosphate particles with a diameter of 0.4-3.0 μm. Tetracalcium phosphate (MW=366.254g / mol) / calcium hydrogen phosphate (MW=136.057g / mol) is mixed at a molar mass ratio of 1 / 2.5 to prepare calcium phosphate composite powder, and 1%-5% of mass percentage of citric acid tri Sodium, building bone substitute material. ddH 2 O (2.5% W / V) double distilled water was used as the liquid phase. Add 100mLddH to 250mg bone substitute material 2 O (2.5% W / V) double distilled water to obtain 2.5mg / mL bone substitute material stock solution, ultrasonically stirred (50% vibration amplitude, 20 seconds) to form a uniform bone substitute material suspens...

Embodiment 3

[0033] Anhydrous calcium hydrogen phosphate and calcium carbonate with a weight ratio of 136.06:100.09 are calcined at 1500°C to form tetracalcium phosphate, which is ground, stirred and sieved to obtain tetracalcium phosphate particles with a diameter of 1-80 μm. Grinding, stirring and sieving to obtain calcium hydrogen phosphate particles with a diameter of 0.4-3.0 μm. Tetracalcium phosphate (MW=366.254g / mol) / calcium hydrogen phosphate (MW=136.057g / mol) is mixed at a molar mass ratio of 1 / 2 to prepare calcium phosphate composite powder, and 1%-5% of citric acid tri Sodium, building bone substitute material. ddH 2 O (2.5% W / V) double distilled water was used as the liquid phase. Add 100mLddH to 250mg bone substitute material 2O (2.5% W / V) double distilled water to obtain 2.5mg / mL bone substitute material stock solution, ultrasonically stirred (50% vibration amplitude, 20 seconds) to form a uniform bone substitute material suspension, measure the microsphere diameter and in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com