Silane/rare-earth composite protective film on aluminum or aluminum alloy surface and preparation method thereof

A technology of aluminum alloy surface and rare earth compounding, applied in the coating process of metal materials, etc., can solve the problems of complex composition of treatment liquid and process, unsatisfactory protective performance of silane film self-healing ability, thin protective film layer, etc., and achieve surface structure Dense, simple process, and the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of treatment solution A: Mix absolute ethanol and distilled water at a ratio of 5:95 to prepare an alcoholic aqueous solution, add 60ml of γ-APS to 940ml of alcoholic aqueous solution, adjust the pH value of the solution to 13 with ammonia water, stir and hydrolyze, and the hydrolysis temperature The temperature is 25°C, the hydrolysis time is 10h, and the solution becomes clear.

[0042] Preparation of treatment solution B: mix 1g sodium hydroxide, 60g CeCl 3 ·7H 2 O and 120ml of hydrogen peroxide solution with a mass concentration of 30% were sequentially added to 820ml of distilled water, mixed evenly, and the distilled water was increased to a volume of 1L, and the pH value of the solution was adjusted to 4 with glacial acetic acid, and placed in a constant temperature water bath at 30°C for later use.

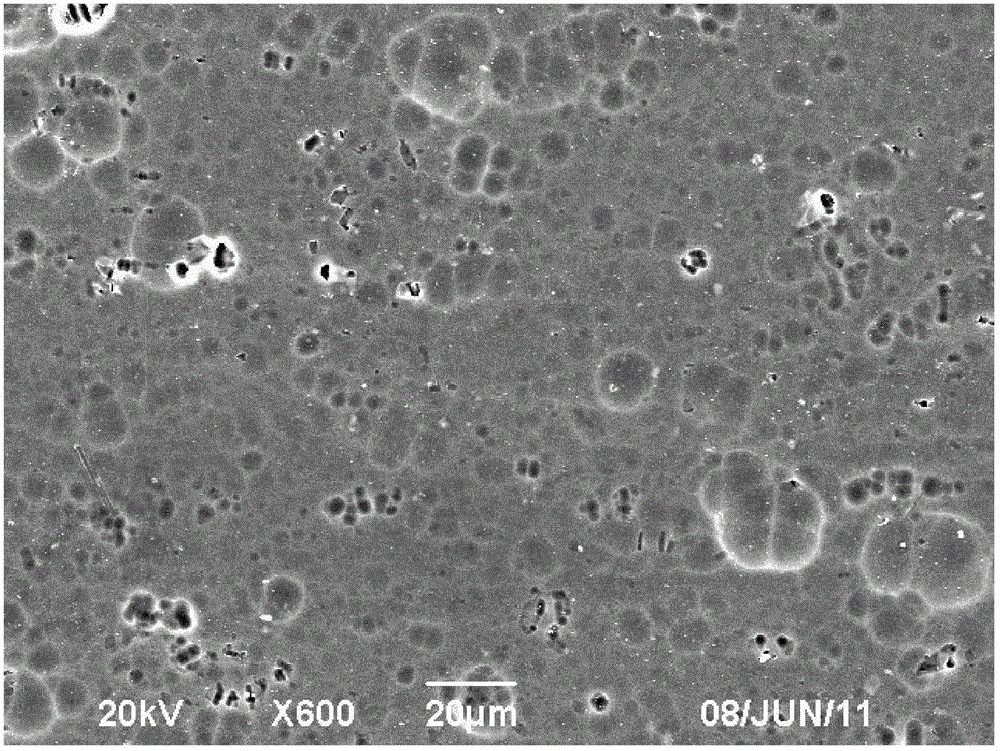

[0043] After conventional pretreatment of 6063 aluminum alloy (sandpaper polishing→water washing→oil removal→water washing→removal of oxide layer→water...

Embodiment 2

[0046] Preparation of treatment solution A: Mix absolute ethanol and distilled water at a ratio of 10:90 to prepare an alcoholic aqueous solution, add 65ml of γ-APS to 935ml of alcoholic aqueous solution, adjust the pH value of the solution to 13 with ammonia water, stir and hydrolyze, and the hydrolysis temperature The temperature is 30°C, the hydrolysis time is 9.5h, and the solution becomes clear.

[0047] Preparation of treatment solution B: mix 3g sodium hydroxide, 70g CeCl 3 ·7H 2 O and 130ml of hydrogen peroxide solution with a mass concentration of 30% were sequentially added to 800ml of distilled water, mixed evenly, and the distilled water was increased to a volume of 1L, and the pH value of the solution was adjusted to 4.5 with glacial acetic acid, and placed in a constant temperature water bath at 35°C for later use.

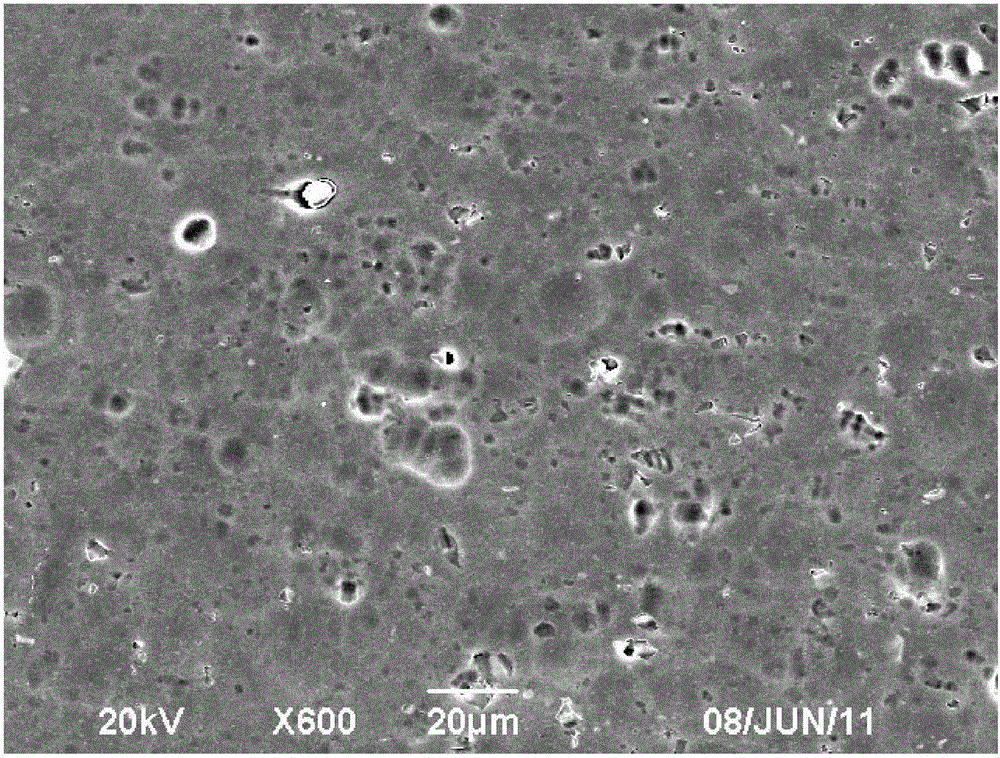

[0048] After conventional pretreatment of 6063 aluminum alloy (sandpaper polishing→water washing→oil removal→water washing→removal of oxide layer→w...

Embodiment 3

[0051] Preparation of treatment solution A: Mix absolute ethanol and distilled water at a ratio of 15:85 to prepare an alcoholic aqueous solution, add 70ml of γ-APS to 930ml of alcoholic aqueous solution, adjust the pH value of the solution to 13 with ammonia water, stir and hydrolyze, and the hydrolysis temperature The temperature was 35°C, the hydrolysis time was 9h, and the solution became clear.

[0052] Preparation of treatment solution B: mix 5g sodium hydroxide, 80g CeCl 3 ·7H 2 O and 140ml of hydrogen peroxide solution with a mass concentration of 30% were sequentially added to 780ml of distilled water, mixed evenly, and the distilled water was increased to a volume of 1L, and the pH value of the solution was adjusted to 5 with glacial acetic acid, and placed in a constant temperature water bath at 40°C for later use.

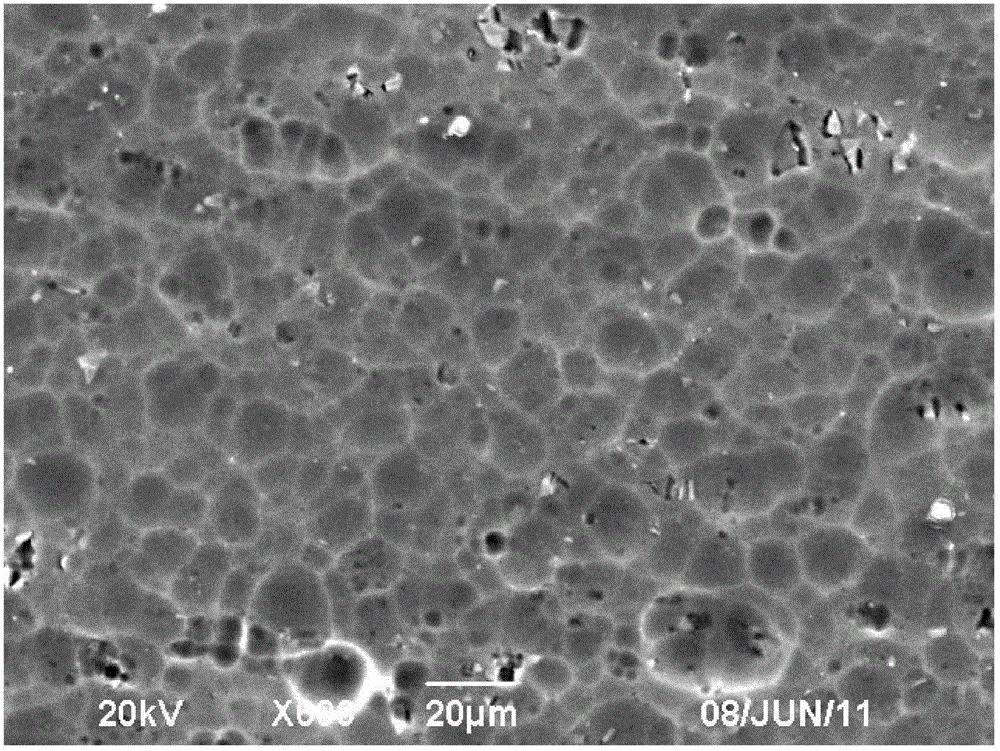

[0053] After conventional pretreatment of 6063 aluminum alloy (sandpaper polishing→water washing→oil removal→water washing→removal of oxide layer→wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com