Polylactic acid oriented microcellular foaming material and preparation method thereof

A technology of microporous foam material and polylactic acid, which is applied in the field of material synthesis, can solve problems such as poor mechanical properties, achieve the effect of reducing product density and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

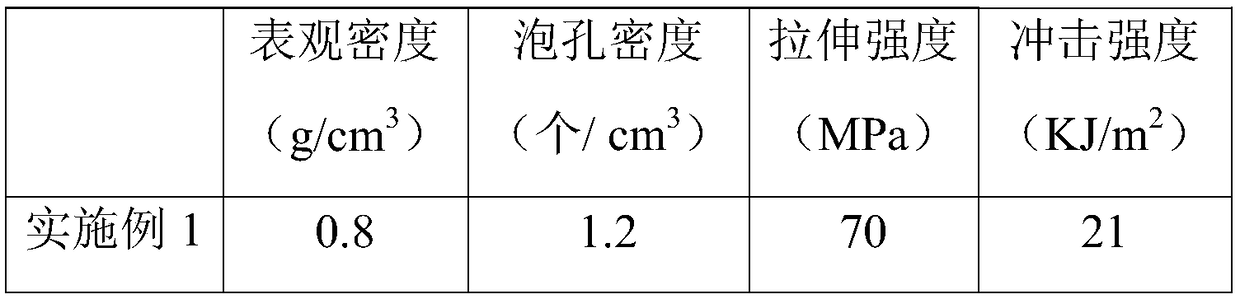

Embodiment 1

[0027] A preparation method of polylactic acid oriented microporous foam material, comprising the following steps:

[0028] (1) The weight average molecular weight of 99.5 parts is 1×10 5 g / mol linear polylactic acid, mixed with 0.5 parts of antioxidant 1010, then dried in a vacuum oven at 80°C for 6 hours, and then placed in a high-speed blender to mix evenly;

[0029] (2) Put the product in step (1) in a co-rotating twin-screw extruder for melt blending, wherein the temperature of each section of the extruder screw is 150°C, 170°C, 180°C, 185°C, 185°C ℃, 170℃, 160℃, the screw speed is 150r / min; then the granules obtained by the extruder are dried in a vacuum oven at 80℃ for 8 hours, and then hot-pressed into dumbbell-shaped splines in a flat vulcanizer , the hot-pressing procedure is: preheating for 5 minutes, hot-pressing for 3 minutes, and cold-pressing for 5 minutes, wherein the hot-pressing temperature is 190°C and the pressure is 10MPa;

[0030] (3) The dumbbell-shape...

Embodiment 2

[0033] A preparation method of polylactic acid oriented microporous foam material, comprising the following steps:

[0034] (1) The weight average molecular weight of 79.5 parts is 1×10 5 g / mol linear polylactic acid, 20 parts weight average molecular weight is 3×10 5 g / mol linear polylactic acid and 0.5 parts of antioxidant 1010 were mixed, then dried in a vacuum oven at 80°C for 6 hours, and then placed in a high-speed blender to mix evenly;

[0035] (2) Put the product in step (1) in a co-rotating twin-screw extruder for melt blending, wherein the temperature of each section of the extruder screw is 160°C, 180°C, 185°C, 190°C, 190°C ℃, 180℃ and 170℃, the screw speed is 150r / min; then the pellets obtained by the extruder are dried in a vacuum oven at 80℃ for 8 hours, and then hot-pressed into a dumbbell-shaped spline in an injection molding machine. Among them, the temperature of each section of the screw of the injection molding machine is 160°C, 170°C, 190°C, and 190°C; ...

Embodiment 3

[0039] A preparation method of polylactic acid oriented microporous foam material, comprising the following steps:

[0040] (1) The weight average molecular weight of 79.5 parts is 1×10 5 g / mol linear polylactic acid, 20 parts weight average molecular weight is 2.1×10 5 g / mol three-arm star-shaped polylactic acid and 0.5 part of antioxidant 1010 were mixed, then dried in a vacuum oven at 80°C for 6 hours, and then placed in a high-speed blender to mix evenly;

[0041] (2) Put the product in step (1) in a co-rotating twin-screw extruder for melt blending, wherein the temperature of each section of the extruder screw is 150°C, 160°C, 170°C, 175°C, 175°C ℃, 170℃, 150℃, the screw speed is 150r / min; then put the pellets made by the extruder in a vacuum oven at 80℃ and dry for 8 hours, and then heat press them into dumbbell-shaped splines in a flat vulcanizer , the hot-pressing procedure is: preheating for 5 minutes, hot-pressing for 3 minutes, and cold-pressing for 5 minutes, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com