Fly ash-based mullite closed-cell ceramic and preparation method thereof

A technology of fly ash and mullite, which is applied in the field of fly ash-based mullite closed-cell ceramics and its preparation, can solve the problems of high thermal conductivity, low closed porosity of materials, unfavorable thermal insulation and other problems, and achieve high strength High efficiency, simple operation and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of fly ash-based mullite closed-cell ceramics, the components are proportioned by mass, fly ash clinker: high alumina bauxite: ammonium bicarbonate: potassium feldspar=100:100:5:10.

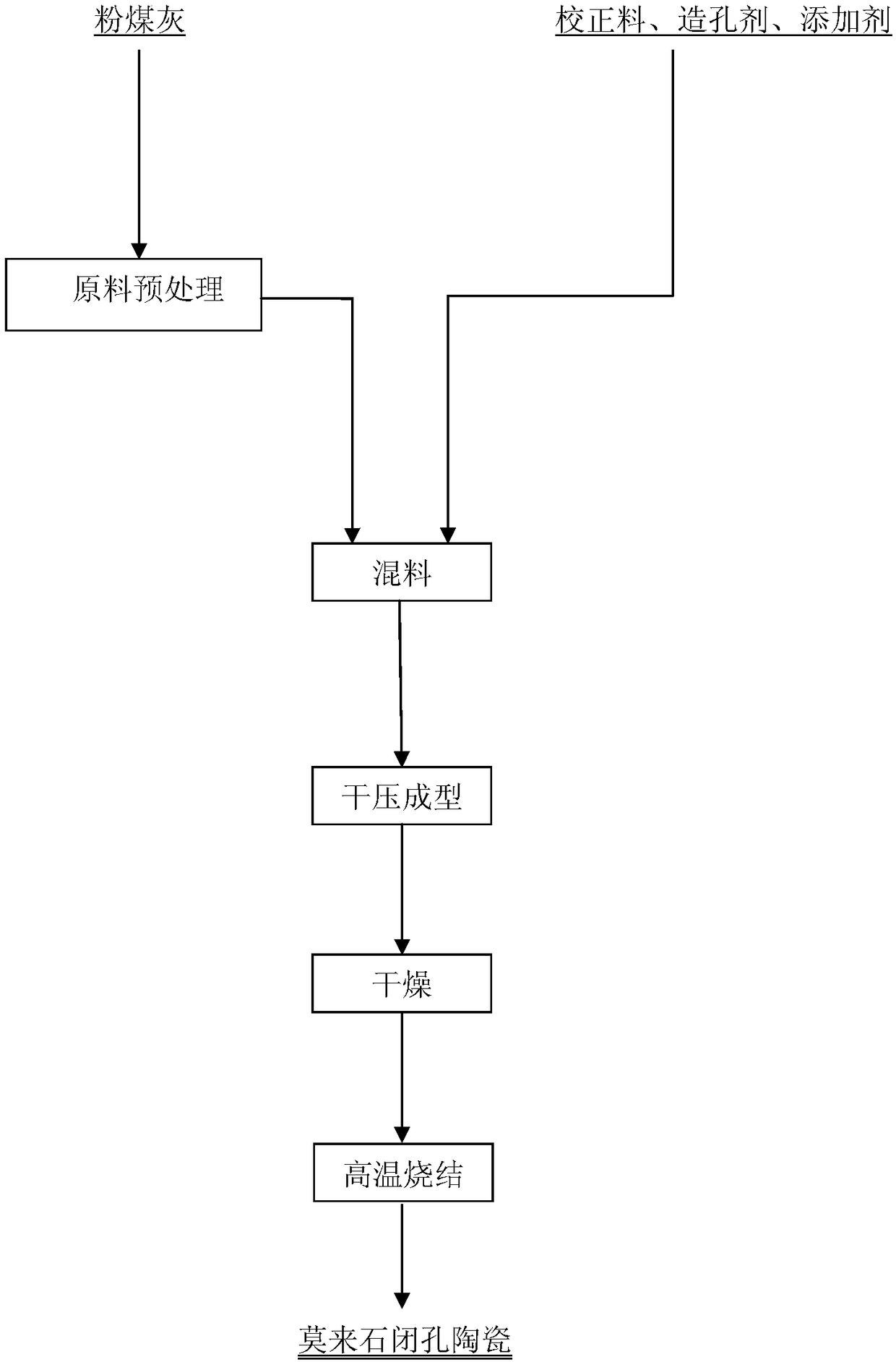

[0037] A preparation method of fly ash-based mullite closed-cell ceramics, the process flow chart is as follows figure 1 shown, proceed as follows:

[0038] Step 1: Raw material pretreatment

[0039] (1) Put the fly ash in a box-type resistance wire furnace and calcinate at 1000°C for 5 hours to obtain fly ash clinker with good stability;

[0040] (2) According to the component distribution ratio of mullite, high-alumina vanadium soil is prepared; wherein, the quality of high-alumina clay is the same as that of fly ash clinker;

[0041] Step 2: Weighing and mixing

[0042] Weigh fly ash clinker, high alumina bauxite, ammonium bicarbonate and potassium feldspar according to the mass ratio of 100:100:5:10, mix and hand grind in an agate crucible for 30 minutes to obtain a mixed mat...

Embodiment 2

[0048] A fly ash-based mullite closed-cell ceramic, the components are proportioned by mass, fly ash clinker: high alumina bauxite: silicon carbide: potassium feldspar=100:100:5:10.

[0049] A preparation method of fly ash-based mullite closed-cell ceramics, the process flow chart is as follows figure 1 shown, proceed as follows:

[0050] Step 1: Raw material pretreatment

[0051] (1) Put the fly ash in a box-type resistance wire furnace and calcinate at 1000°C for 5 hours to obtain fly ash clinker with good stability;

[0052] (2) According to the component distribution ratio of mullite, high-alumina vanadium soil is prepared; wherein, the quality of high-alumina clay is the same as that of fly ash clinker;

[0053] Step 2: Weighing and mixing

[0054] Weigh fly ash clinker, high alumina vanadium, silicon carbide and potassium feldspar according to the mass ratio of 100:100:5:10, mix and hand grind in an agate crucible for 30 minutes to obtain a mixed material;

[0055] S...

Embodiment 3

[0060] A fly ash-based mullite closed-cell ceramic, the components are proportioned by mass, fly ash clinker: alumina powder: ammonium bicarbonate: potassium feldspar=100:100:5:10.

[0061] A preparation method of fly ash-based mullite closed-cell ceramics, the process flow chart is as follows figure 1 shown, proceed as follows:

[0062] Step 1: Raw material pretreatment

[0063] (1) Put the fly ash in a box-type resistance wire furnace and calcinate at 1000°C for 5 hours to obtain fly ash clinker with good stability;

[0064] (2) According to the component distribution ratio of mullite, high-alumina vanadium soil is prepared; wherein, the quality of high-alumina clay is the same as that of fly ash clinker;

[0065] Step 2: Weighing and mixing

[0066] Weigh fly ash clinker, alumina powder, ammonium bicarbonate and potassium feldspar according to the mass ratio of 100:100:5:10, mix and hand grind in an agate crucible for 30 minutes to obtain a mixed material;

[0067] Step 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com