WO3 nano-particle, as well as preparation method and application in sensor thereof

A nanoparticle and sensor technology, which is applied in the field of WO3 nanoparticles and its preparation, can solve the problems that restrict the gas-sensing performance of nanoparticles, and achieve the effects of fast response/recovery, high porosity, reversibility and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

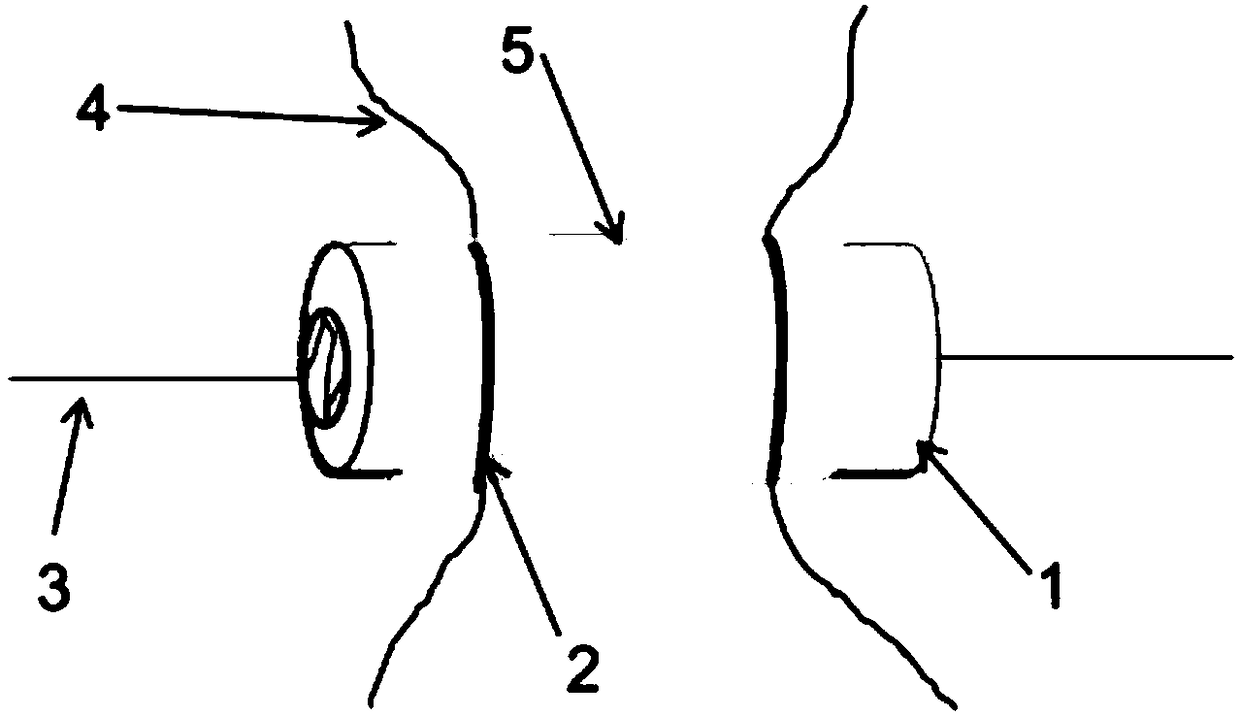

[0039] A gas-sensitive coating is WO 3 The gas sensor of nanoparticles, the schematic diagram of its structure is shown in figure 1 As shown, the heating wire 3 traverses from the ceramic tube 1 and is welded on the heating electrode of the base, the gold electrode 2 covers the outer surface of the ceramic tube 1 and is welded on the measuring electrode of the base through the platinum wire 4, the gas-sensitive coating Layer 5 is coated on gold electrode 2 and Al 2 o 3 Ceramic tube 1 surface.

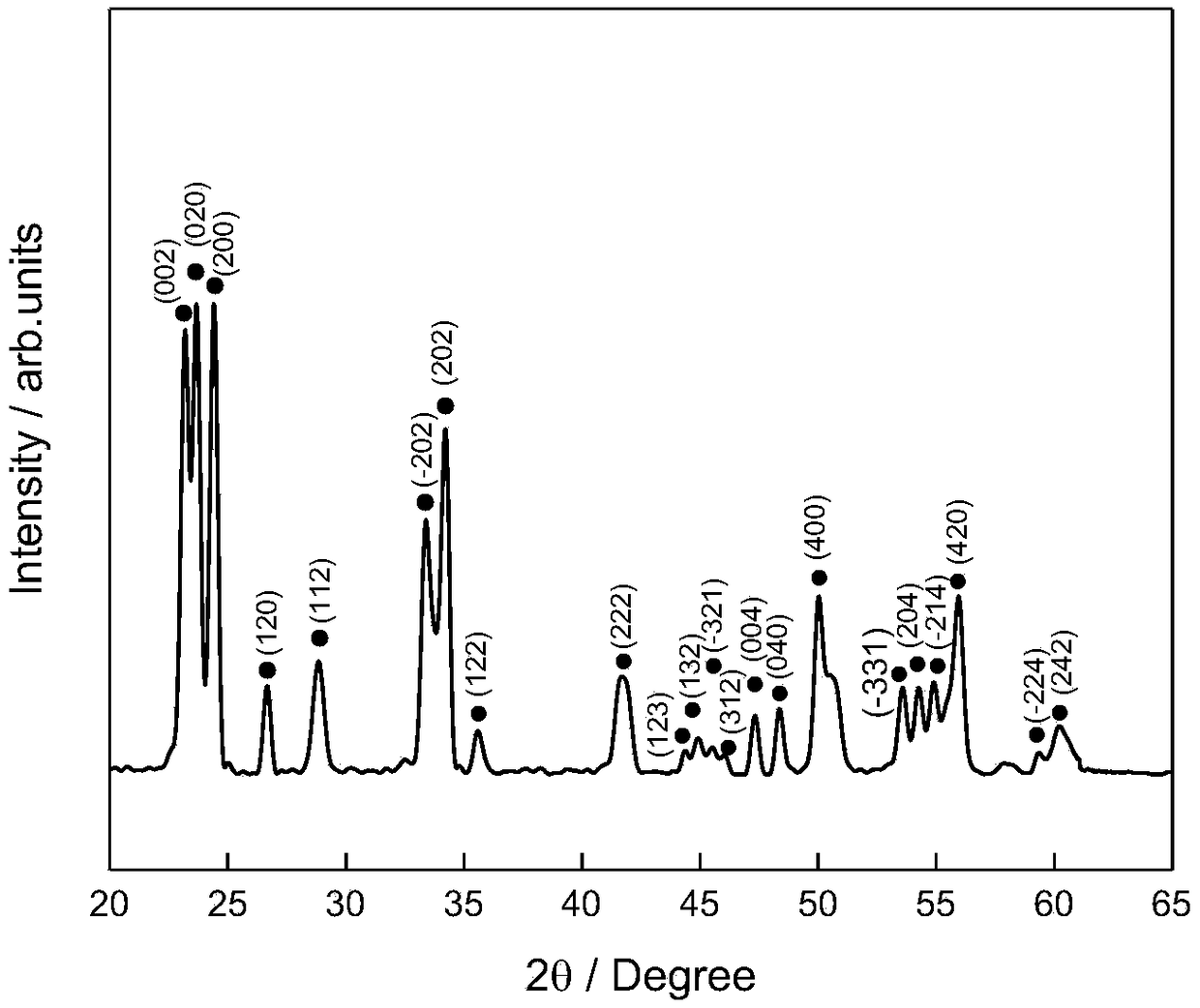

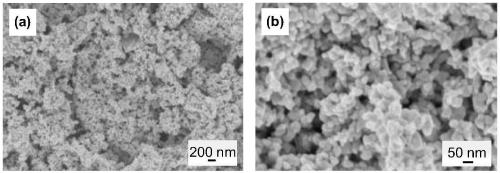

[0040] The composition of the gas-sensitive coating 5 is WO with a single monoclinic crystal structure. 3 Nanoparticles, with a diameter in the range of 10-50nm, have large porosity and specific surface area. Its X-ray diffraction pattern is as figure 2 As shown, the present embodiment prepares WO with a single monoclinic crystal structure. 3 Nanoparticles, without any other impurity diffraction peaks, crystallized in good condition; WO 3 Scanning electron micrographs of nanopa...

Embodiment 2

[0052] A gas-sensitive coating is WO 3 The gas sensor of nanoparticles, the schematic diagram of its structure is shown in figure 1 shown.

[0053] A gas-sensitive coating is WO 3 Nanoparticle NO 2 The preparation method of the gas sensor is carried out according to the following steps:

[0054] ① Weigh 0.10g polyethyleneimine (PEI) and dissolve it in deionized water, stir it magnetically for 10min to ensure full dissolution, and get 6mL concentration of 0.03mol.L -1 Polyethyleneimine (PEI) solution; Weigh 1.48g Na 2 WO 4 2H 2 O was dissolved in deionized water, and magnetically stirred for 5 minutes to obtain a concentration of 0.30mol.L in 15mL-1 Na 2 WO 4 2H 2 O solution; the above two solutions were mixed, and magnetically stirred for 20 minutes to obtain a mixed solution; the concentration of 13mL was 3mol.L -1 The HCl solution was added into the mixed solution, and magnetically stirred for 10 min;

[0055] ② Transfer the mixed solution obtained in step ① to a...

Embodiment 3

[0060] A gas-sensitive coating is WO 3 The gas sensor of nanoparticles, the schematic diagram of its structure is shown in figure 1 shown.

[0061] A gas-sensitive coating is WO 3 Nanoparticle NO 2 The preparation method of the gas sensor is carried out according to the following steps:

[0062] ①Weigh 0.66g Na 2 WO 4 2H 2 Dissolve O in deionized water, stir magnetically for 10 minutes to ensure full dissolution, and obtain a concentration of 0.10mol.L in 20mL -1 Na 2 WO 4 2H 2 O solution; weigh 0.96g polyethyleneimine (PEI) and dissolve it in deionized water, and stir it magnetically for 10min to obtain 16mL with a concentration of 0.10mol.L -1 polyethyleneimine solution; the above two solutions were mixed, and magnetically stirred for 20min to obtain a mixed solution; the concentration of 9mL was 3mol.L -1 The HCl solution was added to the mixed solution, and magnetically stirred for 10 min;

[0063] ② Transfer the mixed solution obtained in step ① to a 100mL po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com