Method and device for preparing graphene based on detonation process

A graphene and detonation technology, which is applied in the field of large-scale graphene preparation based on detonation technology, can solve the problems of high cost restricting the development of graphene materials, expensive single crystal SiC substrates, and harsh preparation process conditions, etc., to achieve large-scale The effect of large-scale production, good consistency and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

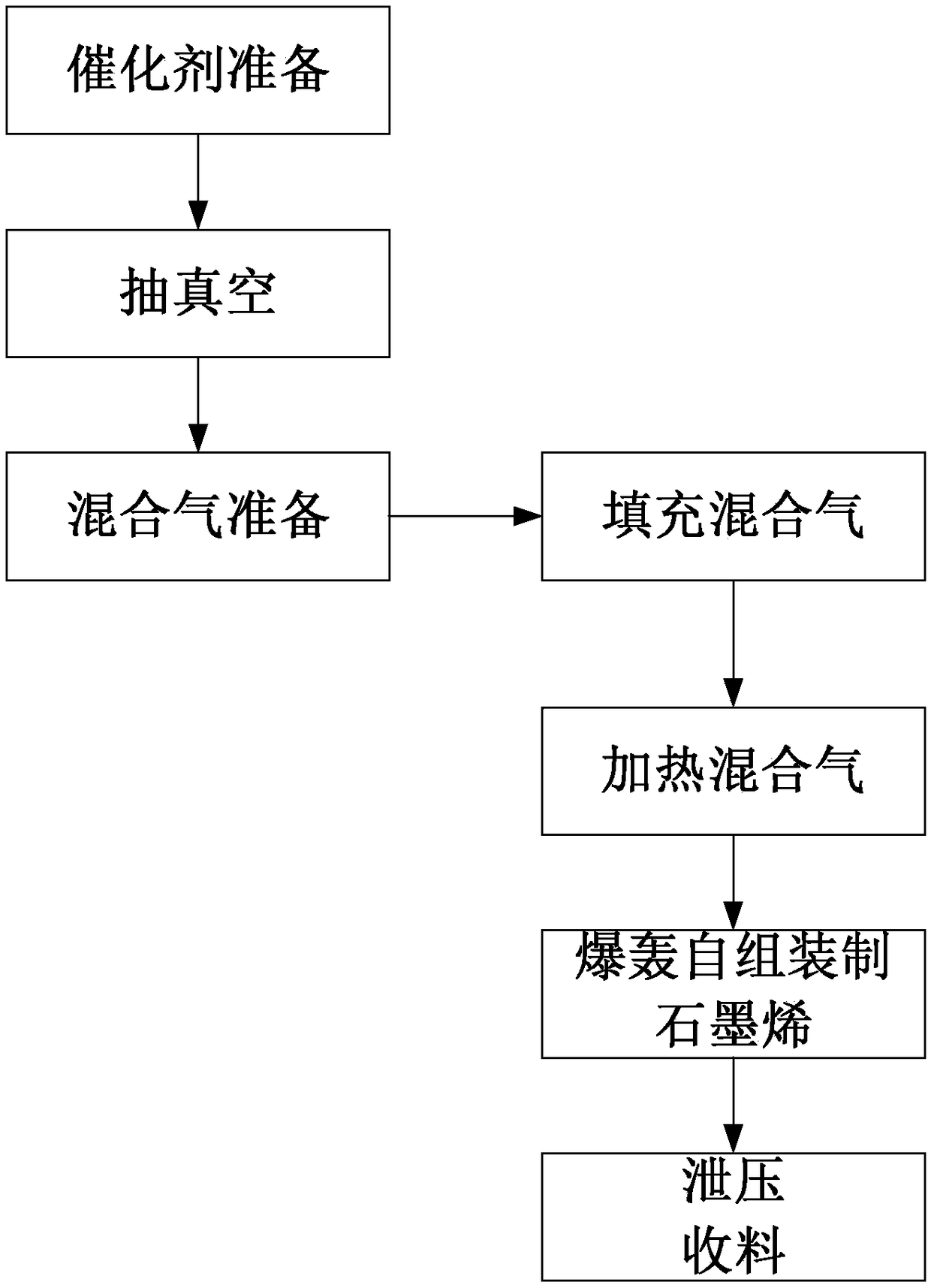

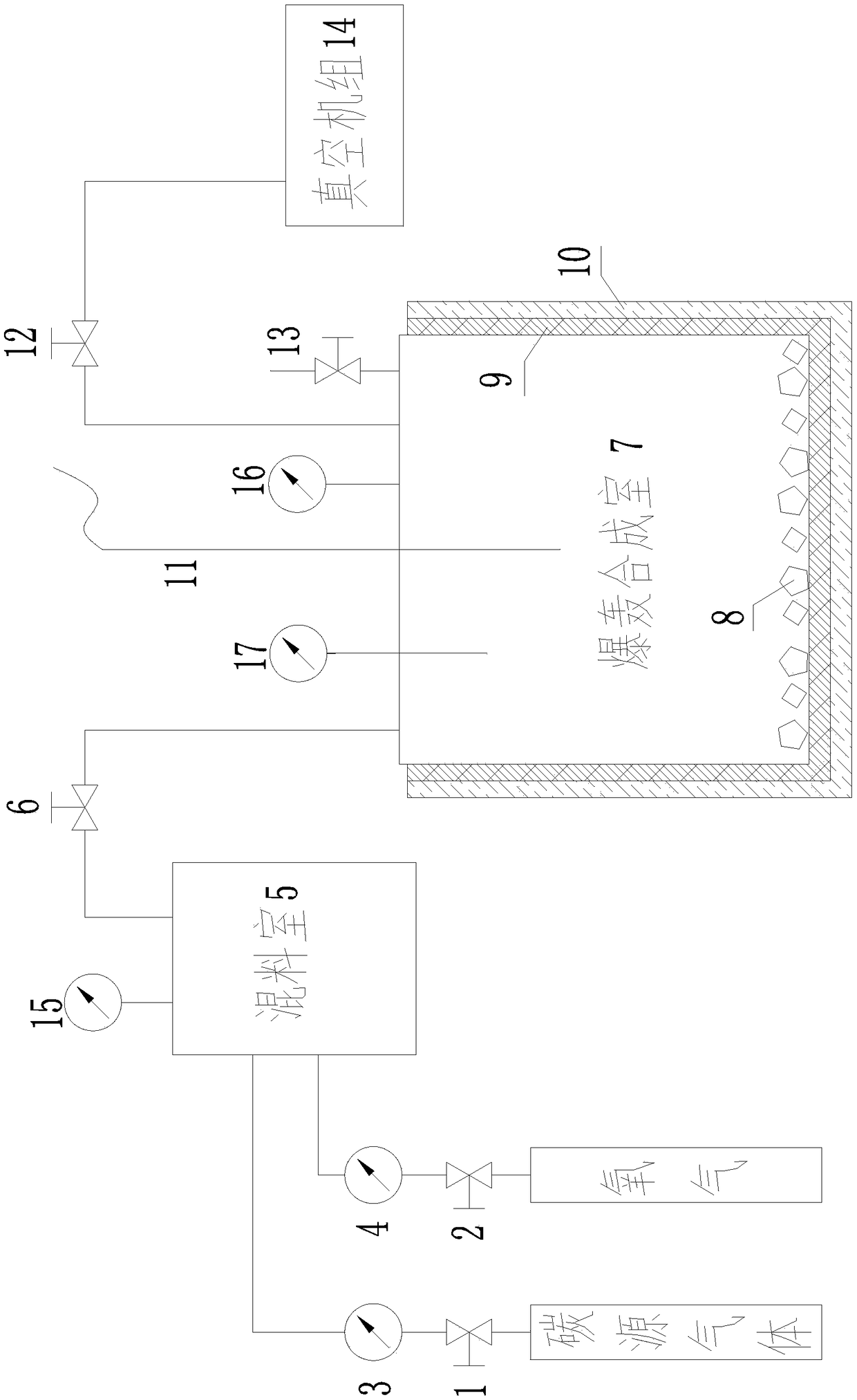

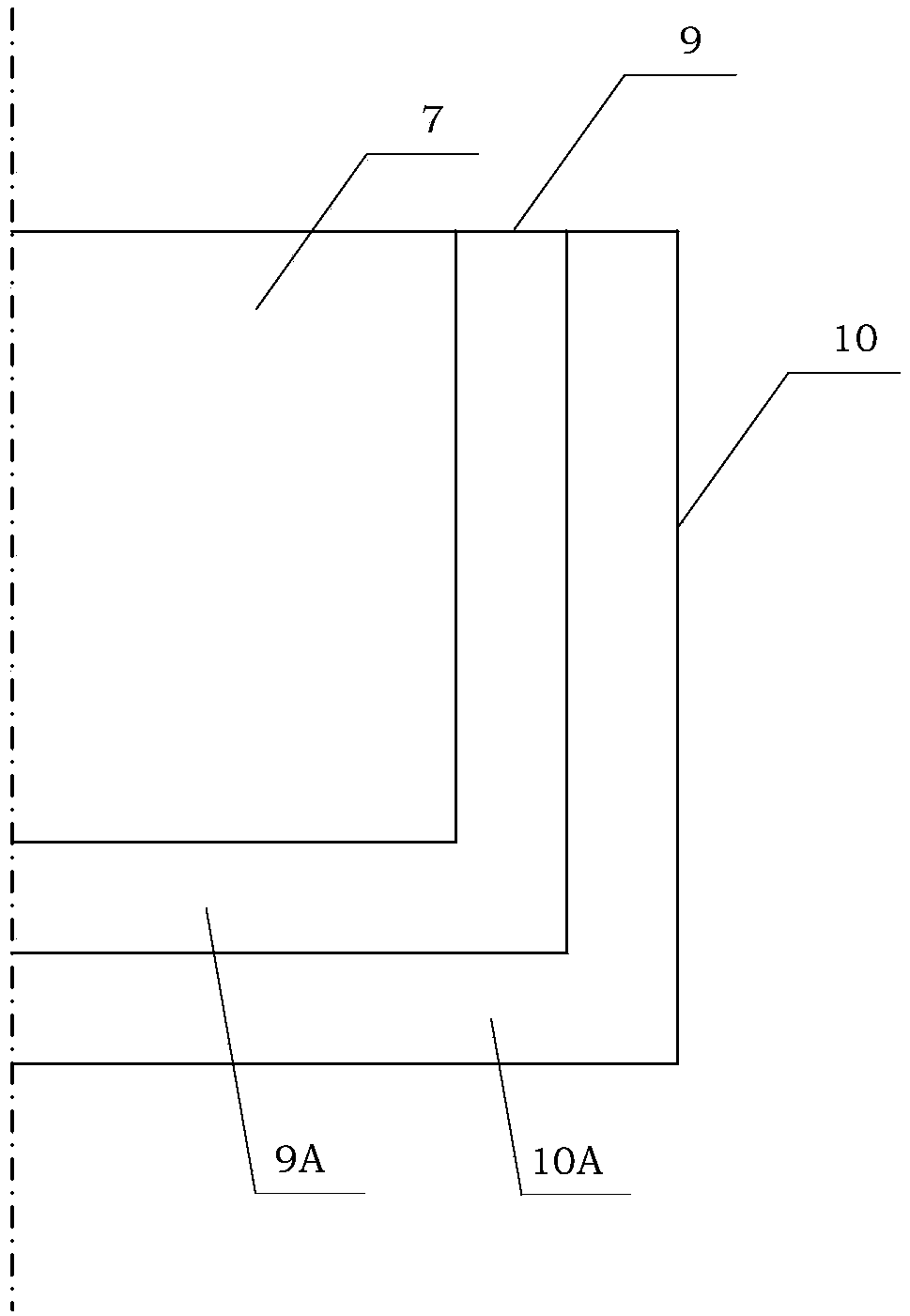

[0095] see figure 1 , figure 2 , Figure 2A , Figure 2B As shown, using acetylene gas as the carbon source gas to prepare graphene

[0096] Step 1, gas source preparation;

[0097] Acetylene gas with a purity ≥ 99.99% is selected as the carbon source, and oxygen with a purity ≥ 99.99% is selected as the deflagration aid;

[0098] Open the carbon source gas valve 1 and the oxygen valve 2; adjust the flow rate of the carbon source gas flow meter 3 and the flow rate of the oxygen flow meter 4;

[0099] Close material valve 6;

[0100] The air pressure in the mixing chamber 5 monitored by the first air gauge 15 is 1MPa;

[0101] Control makes acetylene and oxygen flow in the mixing chamber 5 according to the molar volume ratio of 2:1; The volume of mixing chamber 5 is 50 liters;

[0102] Step 2, catalyst installation;

[0103] Select the detonation synthesis chamber 7 with a volume of 20 liters; open the top cover of the detonation synthesis chamber 7, take by weighing 2...

Embodiment 2

[0123] Preparation of graphene using methane gas as carbon source gas

[0124] Step 1, gas source preparation;

[0125] Choose methane gas with a purity of ≥99.99% as the carbon source, and oxygen with a purity of ≥99.99% as the deflagration aid;

[0126] Open the carbon source gas valve 1 and the oxygen valve 2; adjust the flow rate of the carbon source gas flow meter 3 and the flow rate of the oxygen flow meter 4;

[0127] Close material valve 6;

[0128] It is 0.8MPa to monitor the air pressure in the mixing chamber 5 by the first air gauge 15;

[0129] Control makes methane and oxygen flow in the mixing chamber 5 according to the molar volume ratio of 4:1;

[0130] Step 2, catalyst installation;

[0131] Select the detonation synthesis chamber 7 of volume 20 liters for use; Open the top cover of detonation synthesis chamber 7, 15 grams of purity 99.5%, the iron powder of particle diameter 30~50 microns is evenly sprinkled on the bottom of detonation synthesis chamber a...

Embodiment 3

[0147] Preparation of Graphene Using Cyclohexane as Carbon Source Gas

[0148] Step 1, gas source preparation;

[0149] Choose cyclohexane with a purity ≥99.99% as the carbon source, first heat the cyclohexane to 95°C to make it completely vaporized into gas, and the gas pipeline components and mixing chamber 5 also need to be preheated with an electric heating belt auxiliary heating system to 95°C; choose oxygen with a purity ≥99.99% as a deflagration aid;

[0150] Open the carbon source gas valve 1 and the oxygen valve 2; adjust the flow rate of the carbon source gas flow meter 3 and the flow rate of the oxygen flow meter 4;

[0151] Close material valve 6;

[0152] The air pressure in the mixing chamber 5 monitored by the first air gauge 15 is 1MPa;

[0153] Hexanaphthene and oxygen controlled to vaporize into gas flow into the mixing chamber 5 according to the molar volume ratio of 2:1;

[0154] Step 2, catalyst installation;

[0155] Open the top cover of the detonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com