Warehousing carrying robot and wireless automatic charging method thereof

A technology for handling robots and robots. It is used in current collectors, electric vehicles, electrical components, etc. It can solve the problems of large occupation volume, low work efficiency, slow moving speed, etc., so as to reduce personnel investment, reduce the probability of damage, promote effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

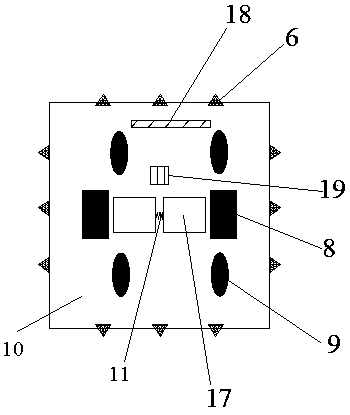

[0031] Please refer to figure 1 , figure 2 and image 3, a storage handling robot in this specific embodiment adopts an embedded design, including a chassis, a casing, a lifting mechanism and a carried sensor, and the lifting mechanism is provided with a bracket for placing objects to be carried; The skeleton and the bottom plate are used to support the overall structure of the robot. The bottom plate is made of steel plates; the main skeleton is set inside the shell, which is composed of upper and lower layers. The inside of the shell is also equipped with obstacle avoidance devices, driving devices, navigation and positioning modules, and control units. , communication unit, lifting mechanism, and charging receiver interface; the control unit, obstacle avoidance device, and lifting mechanism are placed on the second layer of the main frame, and the driving device, navigation positioning module, and charging receiver interface are placed on the first layer of the main frame...

Embodiment 2

[0038] A wireless automatic charging method for the storage and handling robot in Embodiment 1, specifically comprising the following steps:

[0039] S01: Turn on the main switch of the storage robot, insert the charging receiver into the storage handling robot, and connect the charging transmitter to the socket;

[0040] S02: The storage and handling robot automatically monitors the remaining power of the charging receiver. When it is detected that the power of the charging receiver of the storage and handling robot is lower than 50%, the control unit sends an instruction, and the charging receiver and the charging transmitter are automatically connected wirelessly, and then charged after connection The electromagnetic wave receiver of the receiver receives the electromagnetic wave emitted by the charging transmitter and converts the electromagnetic wave into a current, and the rectifier rectifies the current to provide electric energy for the storage and handling robot;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com