Double-layer die pressing machine and die pressing system

A molding machine, double-layer technology, applied in the field of molding equipment, can solve the problems of high production cost, low processing efficiency, large energy, etc., and achieve the effect of improving hot pressing processing efficiency, reducing steam consumption, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

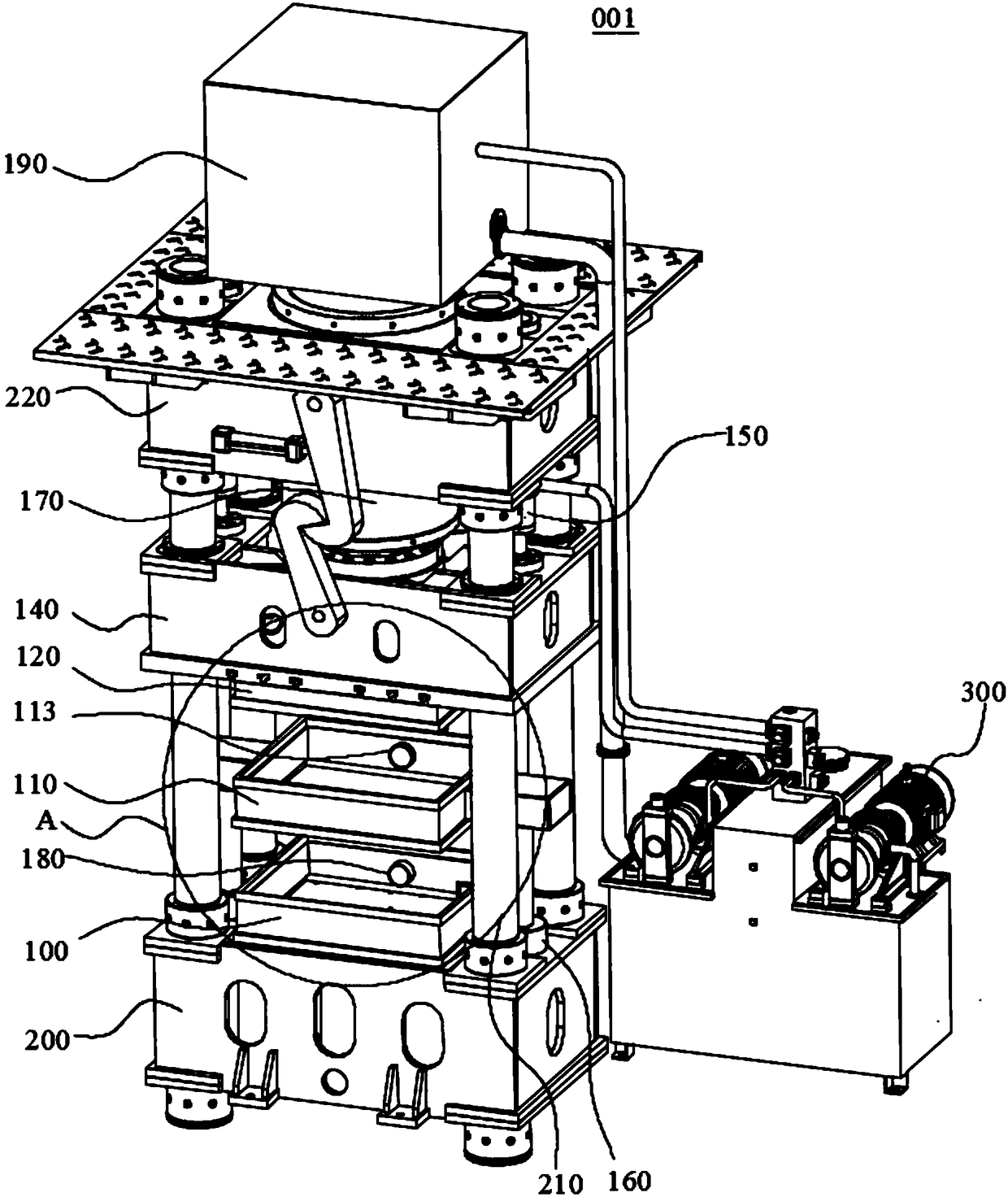

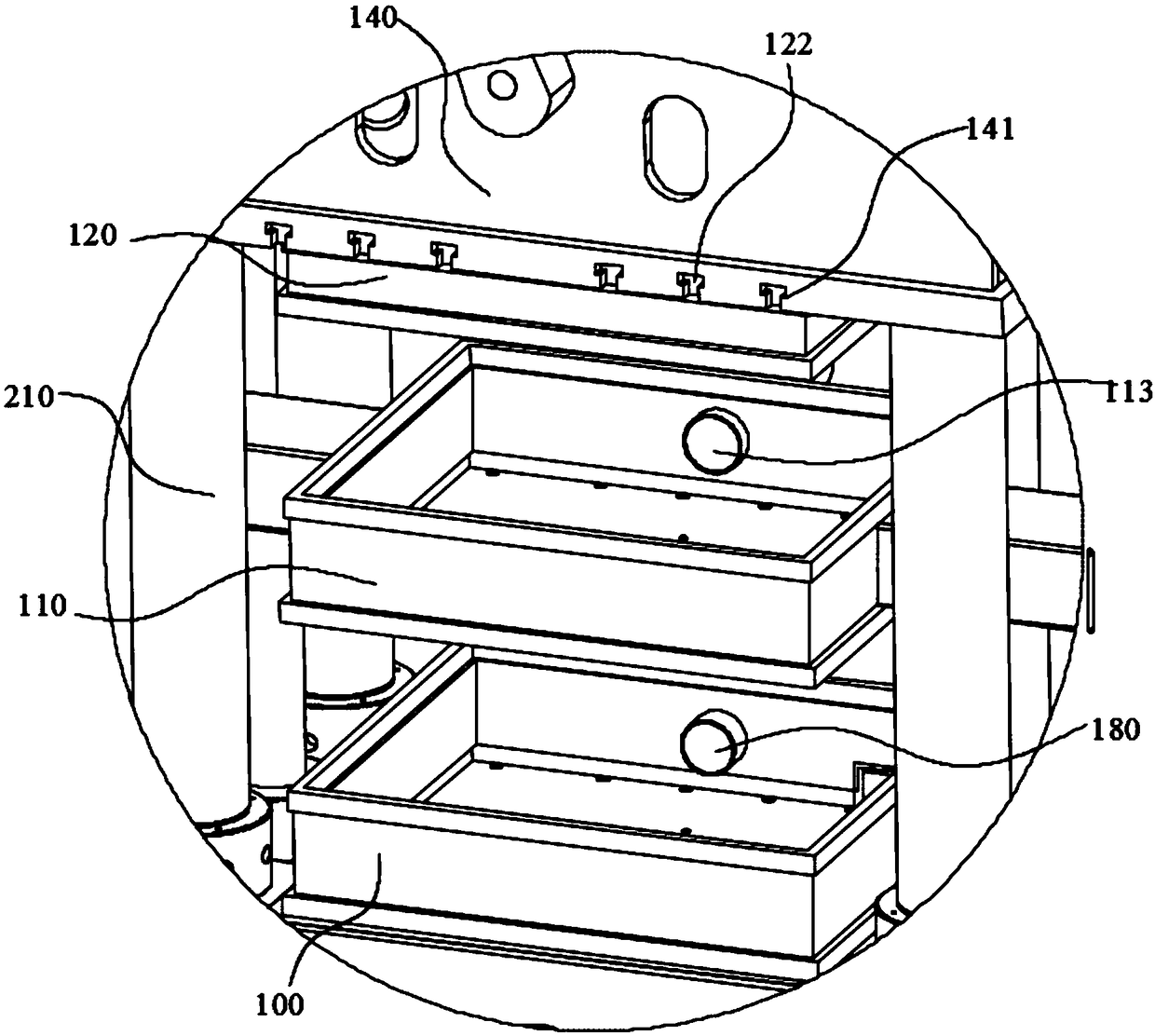

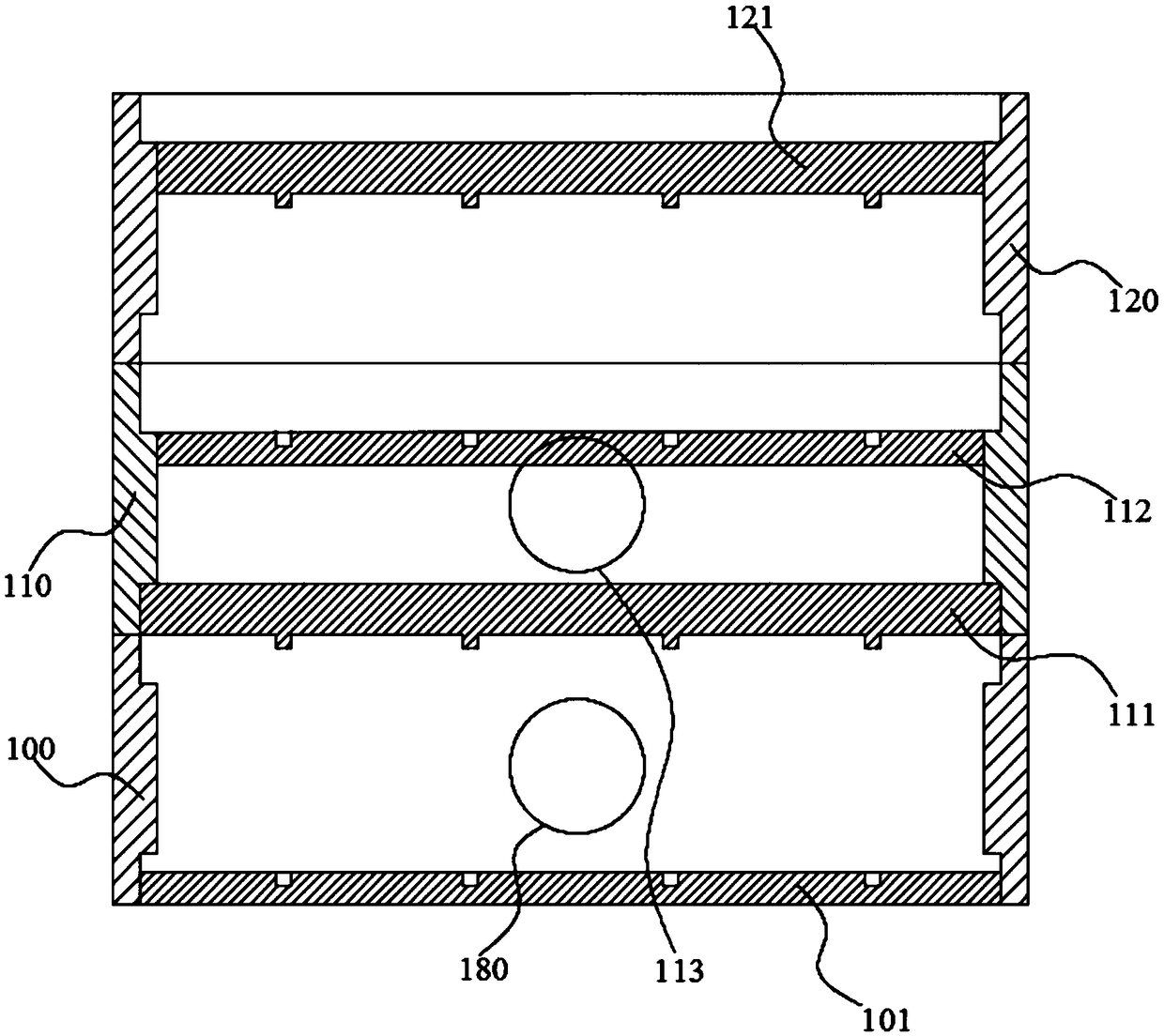

[0032] Please refer to figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment provides a double-layer molding machine 001, which includes a lower mold frame 100, a middle mold frame 110, and an upper mold frame 120 arranged in sequence from bottom to top, and the middle mold frame 110 and the upper mold frame 120 are configured The lower mold frame 100 is provided with a first concave mold 101, the upper mold frame 120 is provided with a first convex mold 121, and the middle mold frame 110 is provided with a first concave mold 101 and a first convex mold 121 respectively. Corresponding to the second male mold 111 and the second female mold 112, the middle mold frame 110 is also connected with a steam pipe 113.

[0033] The double-layer molding machine 001 provided by the embodiment of the present invention can perform molding processing on two polyethylene parts at the same time, and reduce the steam consumption required for processing. When the double-lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com