A kind of metal sheet metal parts image mirrorless processing method

A technology of metal sheet metal parts and processing methods, which is applied in the field of metal sheet metal parts manufacturing, can solve problems such as the inability to form parts with steep side walls, the inability of materials to flow, and the excessive thinning of sheet metal, etc., to achieve rapid response to market demand, Satisfy the product innovation design requirements, the effect of good forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

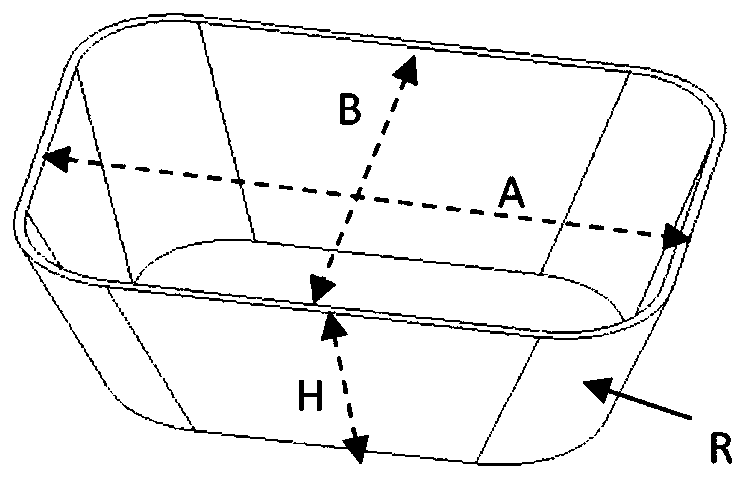

[0021] In this embodiment, the workpiece to be formed is a square box with inclined walls, and the specific shape is as follows: figure 1 As shown, the opening length is represented by A, the width is represented by B, the sidewall fillet radius is represented by R, and the height is represented by H.

[0022] The mirror image processing method of metal sheet metal parts of the present embodiment includes the following steps:

[0023] first step, such as image 3 As shown, the four boundaries of the rectangular sheet are fixed on the forming machine tool through the flexible fixture 1, and the two diagonals of the sheet divide the sheet into four areas, which are respectively marked as I and II in the figure , III, and IV areas, the flexible clamp 1 can adjust the clamping force.

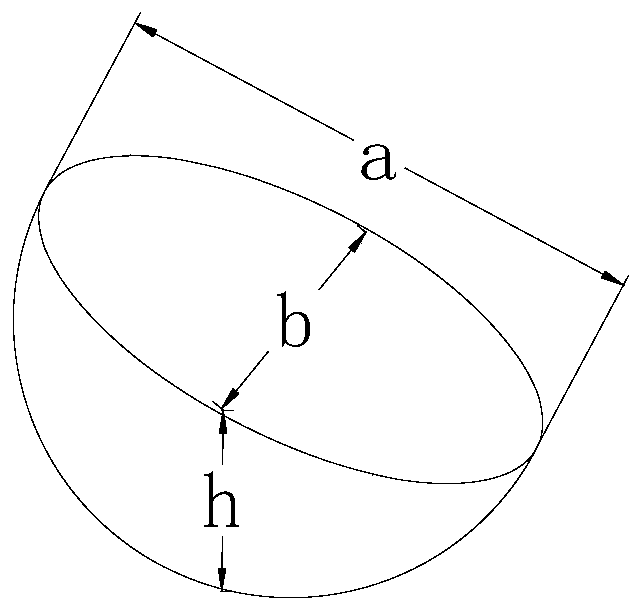

[0024] The second step is to build a figure 2 An intermediate configuration in the shape of a semi-ellipsoid is shown, the two equatorial radii (major and minor axes) of the semi-ellipsoid are h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com