Preparation method and application method of pour point depressant for industrial oleic acid

An application method and technology of pour point depressant, applied in the preparation and application field of industrial oleic acid pour point depressant, to achieve the effect of operability and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Preparation of industrial oleic acid pour point depressant A.

[0030] Add C to a four-neck round bottom flask 20 ~C 24 108 grams of α-olefins, 32 grams of maleic anhydride, equipped with a stirrer, thermometer, condenser, and a feeding funnel with a switch, heat and melt the materials in the flask with an electric heating mantle, start stirring, when the temperature of the materials rises to 150-160 ° C , start to drop 2.8 grams of di-tert-butyl peroxide, the time for adding di-tert-butyl peroxide is 3.5 hours, during the dropping process, the temperature of the material is controlled at 150-180°C, after the addition is completed, Continue to stir at 150-180°C for 0.5 hour, take a copolymer sample, then add 173 grams of industrial oleic acid to terminate the polymerization reaction and dilute the copolymer, stir well to obtain industrial oleic acid pour point depressant A.

[0031] The melting point of the copolymer sample was determined to be 90°C.

[0032] The aci...

example 2

[0035] Preparation of industrial oleic acid pour point depressant B.

[0036] Add C to a four-neck round bottom flask 20 ~C 28 110 grams of alpha olefin, 30.8 grams of maleic anhydride, equipped with a stirrer, thermometer, condenser, and a feeding funnel with a switch, heat and melt the contents of the flask with an electric heating mantle, start stirring, when the temperature of the contents rises to 155-170 ° C , start to drop 2.7 grams of di-tert-butyl peroxide. The time for adding di-tert-butyl peroxide is 4 hours. , continue stirring at 150-180° C. for 0.5 hour, take a copolymer sample, then add 170 grams of industrial oleic acid, stir well to obtain industrial oleic acid pour point depressant B.

[0037] The melting point of the copolymer sample was determined to be 85°C.

[0038] The acid values of the industrial oleic acid sample and the pour point depressant B sample used in the test were measured respectively. The acid value of the industrial oleic acid was 196...

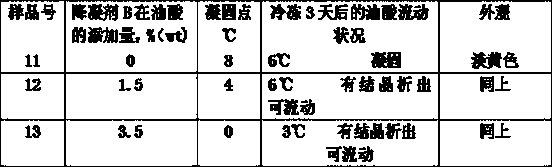

example 3

[0041] Add the pour point depressant A prepared in Example 1 to industrial oleic acid 1 and industrial oleic acid 2 at 15°C, mix well, measure the freezing point of industrial oleic acid, and freeze industrial oleic acid for 3 days at 6°C and 3°C. Observe its mobility, and the test results are listed in Table 1 and Table 2.

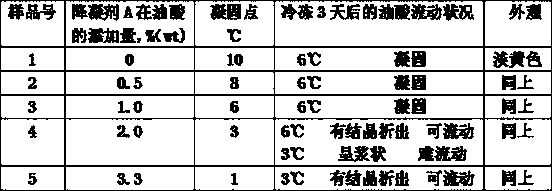

[0042] Table 1 Application test of pour point depressant A in industrial oleic acid I

[0043]

[0044] Note: The precipitated crystals are in the form of dispersed particles

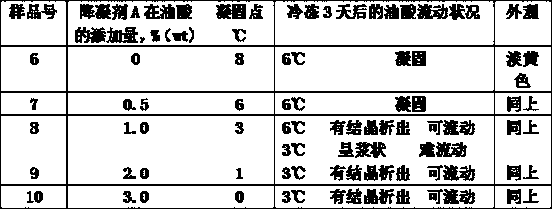

[0045] Table 2 Application test of pour point depressant A in industrial oleic acid II

[0046]

[0047] Note: The precipitated crystals are in the form of dispersed particles

[0048] The results in Table 1 and Table 2 show that adding the pour point depressant A prepared in Example 1 to the industrial oleic acid whose temperature is 5°C and 7°C higher than its own freezing point can lower the freezing point of the industrial oleic acid. When the amount is appropriate, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com