Dysprosium-activated crystal material capable of achieving yellow laser output

A crystalline material and single crystal technology, applied in the field of inorganic crystalline materials, can solve problems such as complex systems, and achieve the effects of high thermal conductivity, high mechanical strength, and high laser damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation of embodiment 1 crystal material sample

[0049] Weigh CaCO according to the ratio in the following chemical reaction formula 3 , La 2 o 3 , Ga 2 o 3 and Dy 2 o 3 , mix well to get the raw material:

[0050] 2CaCO 3 +(1-x)La 2 o 3 +3Ga 2 o 3 +xDy 2 o 3 →2CaGy y La (1-x) Ga 3 o 7 +2CO 2 ↑

[0051] Press the raw material into a sheet, put it into a corundum crucible, put it into a high-temperature sintering furnace, slowly raise the temperature to 1000-1100 at a certain rate, and keep it for a period of time; then raise the temperature to the sintering temperature and sinter at a constant temperature for a period of time, take out the sample; repeat the above sintering step until X-ray powder diffraction with CaLaGa 3 o 7 Until the XRD standard JCPDS card of the crystal completely matches, a polycrystalline sample of the crystal material is obtained.

[0052] Put the raw materials into the iridium crucible of Ф53mm×30mm. In order to a...

Embodiment 2

[0056] The optical property measurement of embodiment 2 gained sample

[0057] Take sample S1 separately # ~S3 # , the processed size is 3.0×5.0×1.0mm 3 The crystal slices were tested for spectral properties.

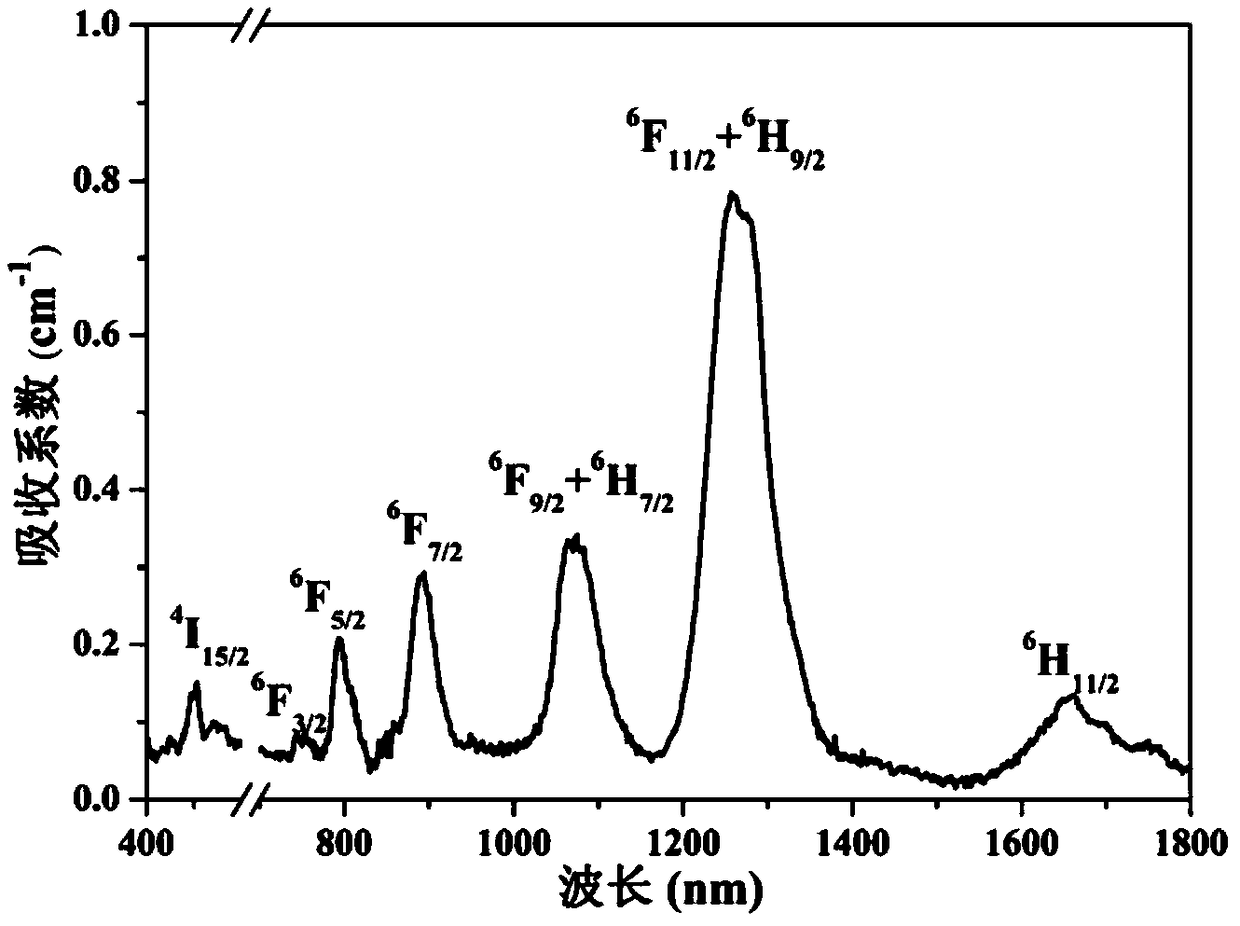

[0058] The results showed that sample S1 # ~S3 # The absorption spectrum of Dy shows 3+ The characteristic absorption peaks of , where the peak wavelengths are 453, 756, 799, 894, 1075, 1257 and 1662nm, respectively, corresponding to Dy: 6 h 15 / 2 arrive 4 I 15 / 2 , 6 f 3 / 2 , 6 f 5 / 2 , 6 f 7 / 2 , 6 f 9 / 2 + 6 h 7 / 2 , 6 f 11 / 2 + 6 h 9 / 2 with 6 h 11 / 2 transition, wherein the absorption peak is located in the 435-463nm band, and the peak wavelength is 453nm. This absorption band matches the commercial blue light semiconductor pump source, making Dy:CaLaGa 3 o 7 The crystal is well suited for laser experiments with commercial blue diode pumping.

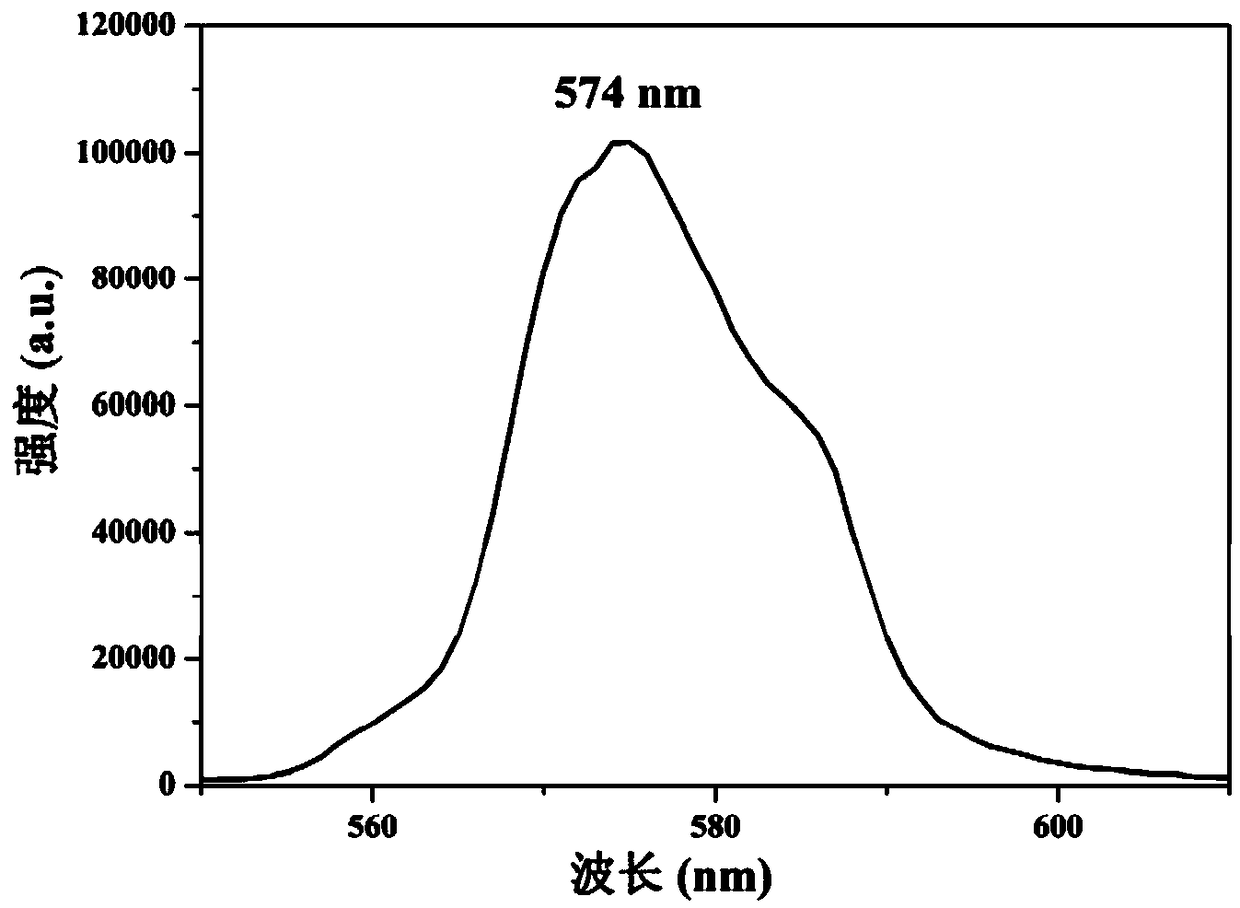

[0059] The room temperature fluorescence spectrum under pumping at 453nm shows that sample S1 # ~S3 # T...

Embodiment 3

[0062] The application of embodiment 3 gained sample in laser device

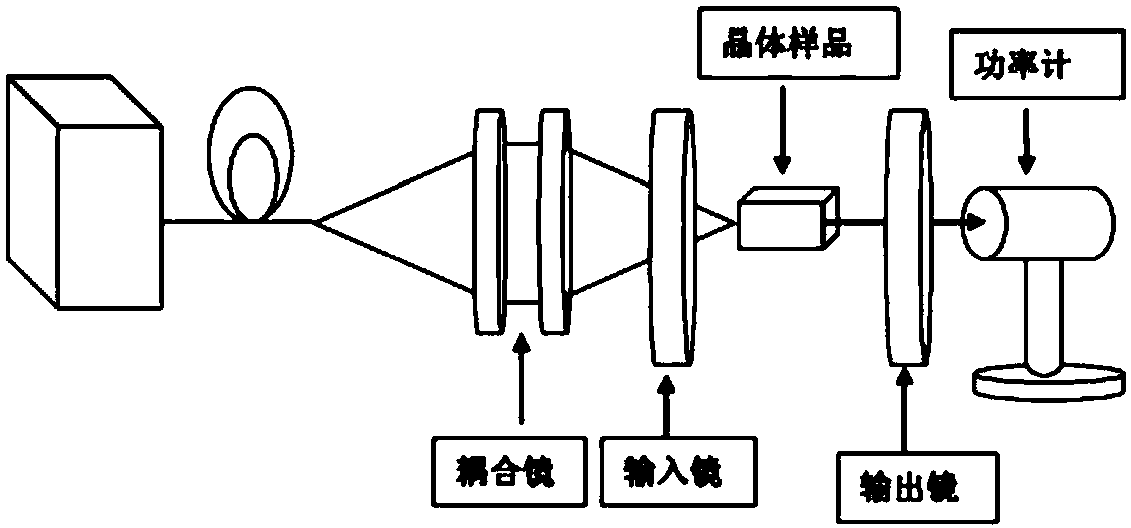

[0063] Take sample S1 separately # ~S3 # , the processed size is 2mm×2mm×(5~10)mm, the two ends of the crystal are 2mm×2mm polished, and it is applied to the laser device. The device diagram of the laser device is shown in image 3 As shown, the crystal sample is put into a water-sealed copper tube, the pump source used is 453nm blue light LD, and the end-pump mode is adopted. The input mirror is a concave mirror with a diameter of 200mm, which is highly transparent at 453nm and highly reflective at 574nm. The coupling mirrors are plane mirrors with transmittances of 1%, 2% and 3% at the laser wavelength. The laser spectrum is measured by a laser wavelength meter, the model is 821B-IR, Bristol, and the laser power is measured by a power meter, the model is LPE-1B.

[0064] The results showed that the samples S1 were applied respectively # ~S3 # All laser devices can achieve 574nm yellow laser output. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com