Light-emitting material for plant light-controlled development, preparation method of light-emitting material, and light-emitting device

The technology of a luminescent material and a luminescent device is applied in the field of luminescent materials for light-controlled development of plants and their preparation, which can solve the problems of expensive plant growth lamps and lack of luminescent materials, and achieve the effects of simple manufacturing process, low production cost and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

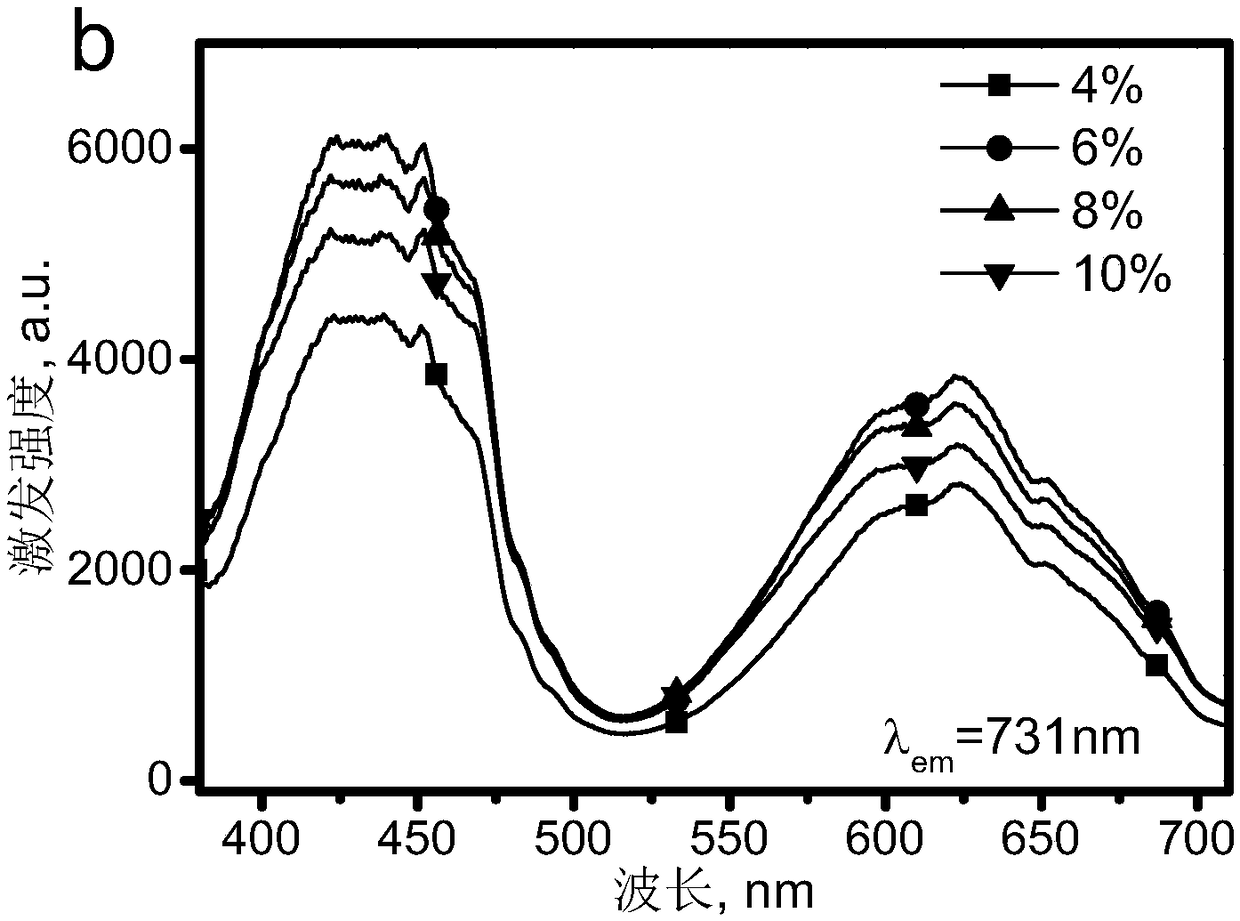

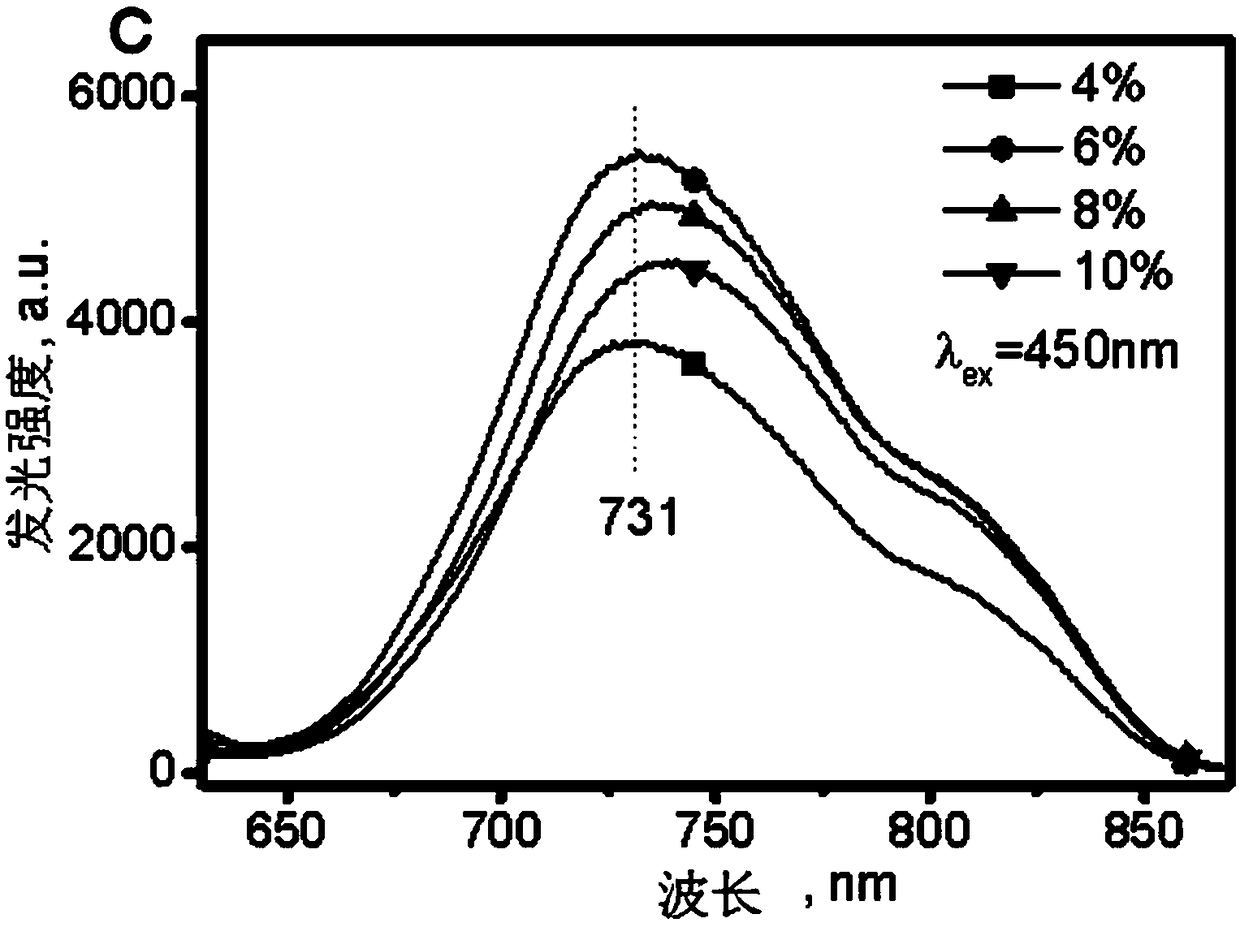

[0055] Cr 3+ Concentration optimization:

[0056] (1) According to the chemical formula [K 3 (Al 1-x Cr x )]F 6 , the values of x are 0.04, 0.06, 0.08, 0.10, KF and K 3 BF 6 The molar ratio of 2:1, respectively weighed CrF 3 , KF and K 3 AlF 3 ;

[0057] (2) CrF 3 Pour into polyvinyl fluoride reactor, according to CrF 3 , KF and K 3 AlF 3 The mass ratio of total mass to hydrofluoric acid is 40%, add hydrofluoric acid, stir to make it dissolve;

[0058] (3) Add KF to the product of step (2), and then add K after KF dissolves 3 AlF 6 , the reactor was sealed and kept stirring for 30 min;

[0059] (4) After step (3) stops stirring, carry out suction filtration to reaction product, use acetone to wash reaction product repeatedly, until no acidity is detected;

[0060] (5) Take the filter cake and dry it under vacuum at 70°C, and the obtained luminescent material is K 3 AlF 6 : Cr phosphor.

[0061] Experimental results: use X-ray diffractometer (Panalytical, ...

Embodiment 2

[0063] Optimization of the solid-liquid ratio of the reaction system: the solid-liquid ratio in the reaction system is K 3 AlF 6 , KF and CrF 3 The ratio of the mass of all solids to the mass of hydrofluoric acid liquid

[0064] (1) According to the chemical formula [K 3 (Al 0.94 Cr 0.06 )]F 6 , KF and K 3 AlF 6 The molar ratio of 2:1 weighs respectively CrF 3 , KF and K 3 AlF 3 ;

[0065] (2) CrF 3 Pour into polyvinyl fluoride reactor, according to CrF 3 , KF and K 3 AlF 3 The concentration ratio of the total mass of the solid powder to the sum of the hydrofluoric acid liquid mass is respectively 20%, 30%, 40%, 50% and 60%, adding hydrofluoric acid and stirring to dissolve it;

[0066] (3) Add KF to the product of step (2), and then add K after KF dissolves 3 AlF 6 , the reactor is sealed, stirred and reacted for 30min;

[0067] (4) After step (3) stops stirring, carry out suction filtration to reaction product, use acetone to wash reaction product repeatedl...

Embodiment 3

[0072] Optimizing Matrix Components:

[0073] (1) with CrF 3 , KF, K 3 AlF 3 and Na 3 AlF 3 as raw material, adjust K 3 AlF 6 with Na 3 AlF 6 The proportion of Cr 3+ The concentration is set to 6%, KF and ((1-x)K 3 AlF 6 +xNa 3 AlF 6 ) The mol ratio is set to 2:1;

[0074] (2) According to the chemical formula (K 1-x Na x ) 3 al 0.94 Cr 0.06 f 6 , the value of x is 0.1, 0.2, 0.3, 0.4, 0.5, weigh CrF 3 、K 3 AlF 3 and Na 3 AlF 3 , and follow KF with K 3 AlF 6 and Na 3 AlF 6 The mol ratio of sum is 2:1 and takes by weighing KF;

[0075] (3) CrF3 is poured into the polyvinyl fluoride reactor, and hydrofluoric acid is added according to the solid-to-liquid ratio of the system being 40%, and stirred to make it dissolve;

[0076] (4) Add KF to the product of step (2), and then add Na after KF dissolves 3 AlF 6 , the reactor was sealed and kept stirring for 30 min;

[0077] (5) After step (3) stops stirring, carry out suction filtration to reaction prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com